DE08TS Diesel Engines Maintenance

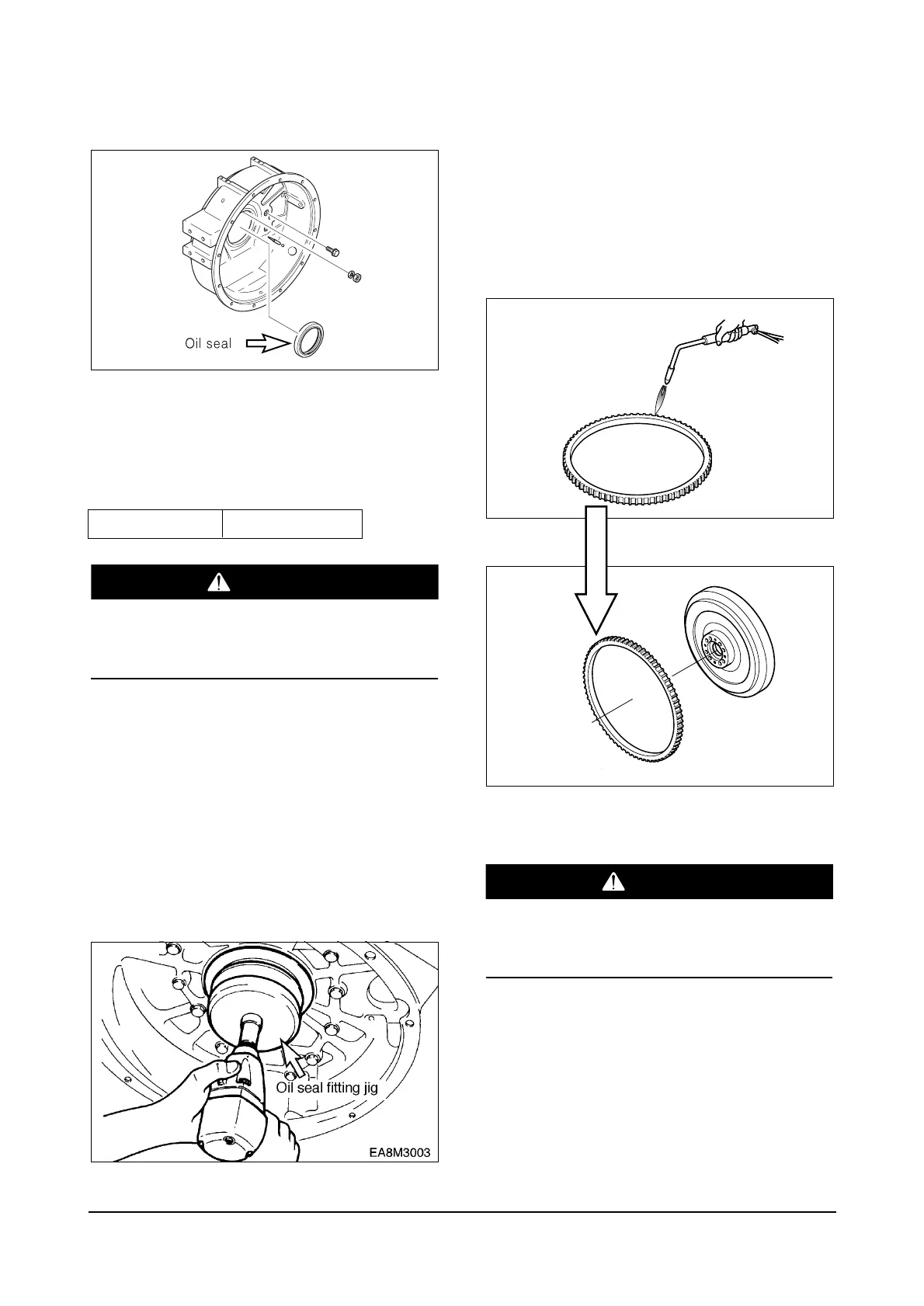

Flywheel housing

1. Temporarily install the guide bar on the cylinder

block.

2. Apply gasket to the cylinder block.

3. Using the dowel pin and guide bar, install the fly-

wheel housing and tighten the fixing bolts in a diag-

onal sequence to specified torque. (Zigzag method)

When the bolts are tightened, remove the guide

bar.

4. The flywheel housing is assembled after the new oil

seal was pressed (Coat engine oil over the outside

of oil seal) before in the housing by a press.

5. If any peripheral scar was generated due to oil seal

at the oil seal contact surface of crankshaft, after

inserting about 1 mm shim or thereabout in front of

oil seal (Direction toward crankshaft.), measure and

adjust.

Oil seal (Rear side)

1. Apply lubricating oil to the outside of the oil seal and

flywheel housing inside diameter and fit them over

the crank shaft, then assemble the oil seal using an

oil seal fitting jig.

Flywheel

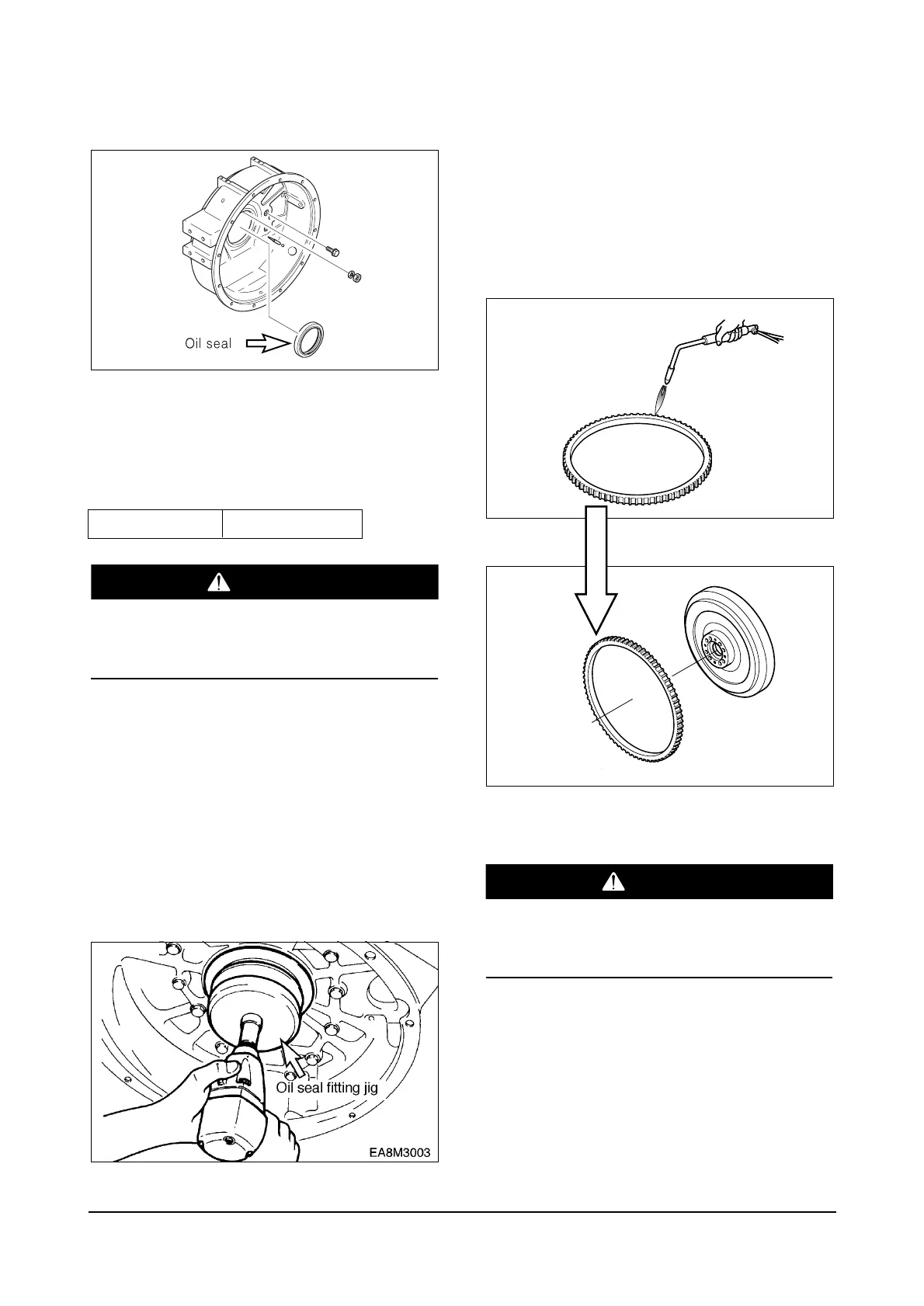

• Installation of flywheel ring gear

With a gas burner, heat the ring gear evenly until heat

expansion takes place, then install it using a hammer.

Do not allow the temperature of the ring gear to

exceed 200 °C (390 °F).

2. By means of mandrel, assemble pilot bearing to the

flywheel.

3. By means of mandrel, press in the wear ring at the

backward face.

WARNING

EA6M2004

Wear ring Ring gear

EA0M4029

WARNING

EB5M3004

52

Torque 8 kg

•

m

Loading...

Loading...