DE08TS Diesel Engines Maintenance

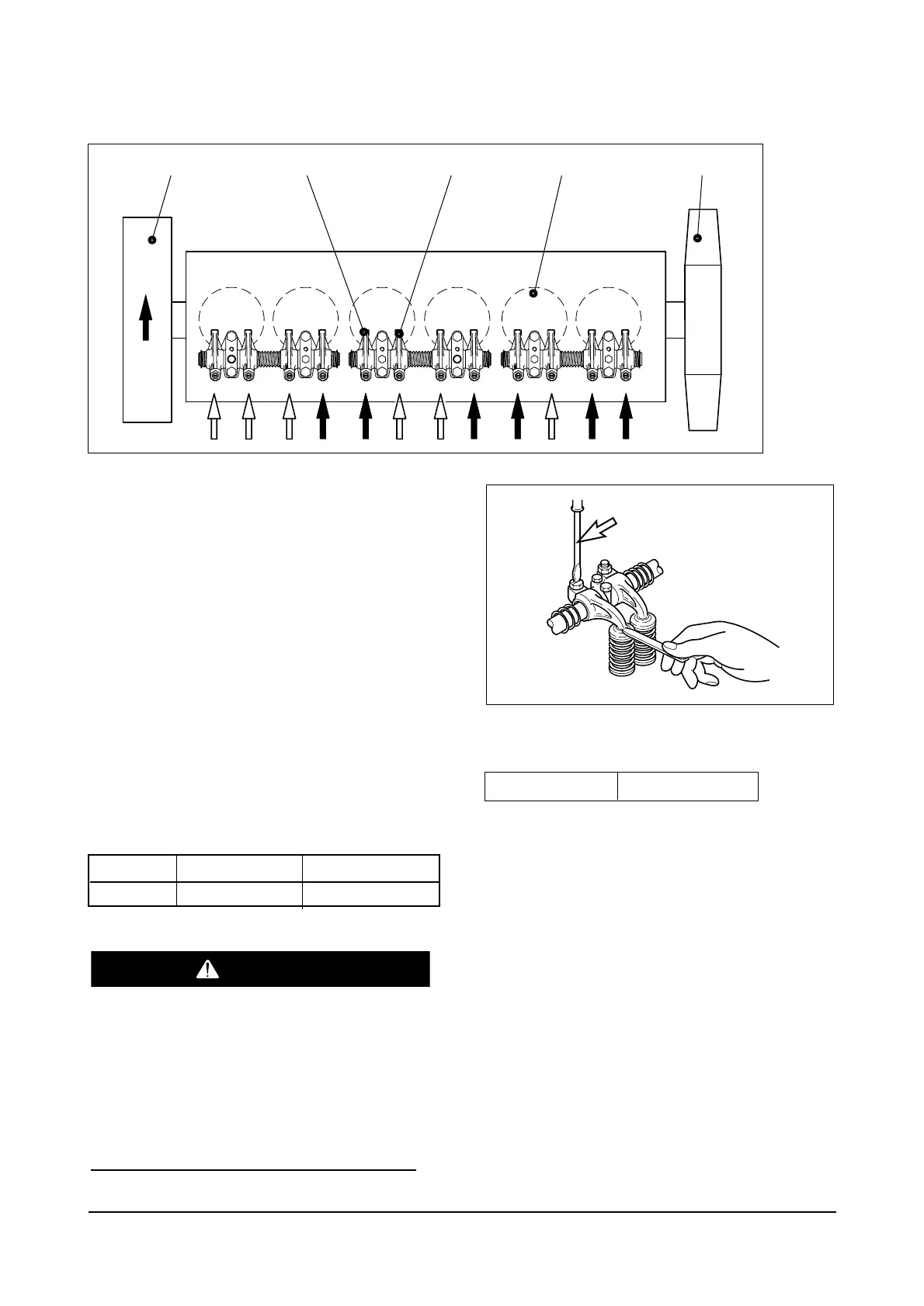

<Guide for valve clearance adjustment>

a. By turning the crankshaft, when the intake and

exhaust of #6 cylinder (the sixth cylinder from the

flywheel) overlap, that is, when #1 cylinder’s pis-

ton come at the compression top dead center

(OT), adjust the valve clearances by mark indicat-

ed.

b. After having turned the crankshaft by 360° and

Intake & exhaust valves of #1 cylinder overlap,

that is, when #6 cylinder is in the state of com-

pression TDC (OT), the clearance indicated by

mark is adjusted.

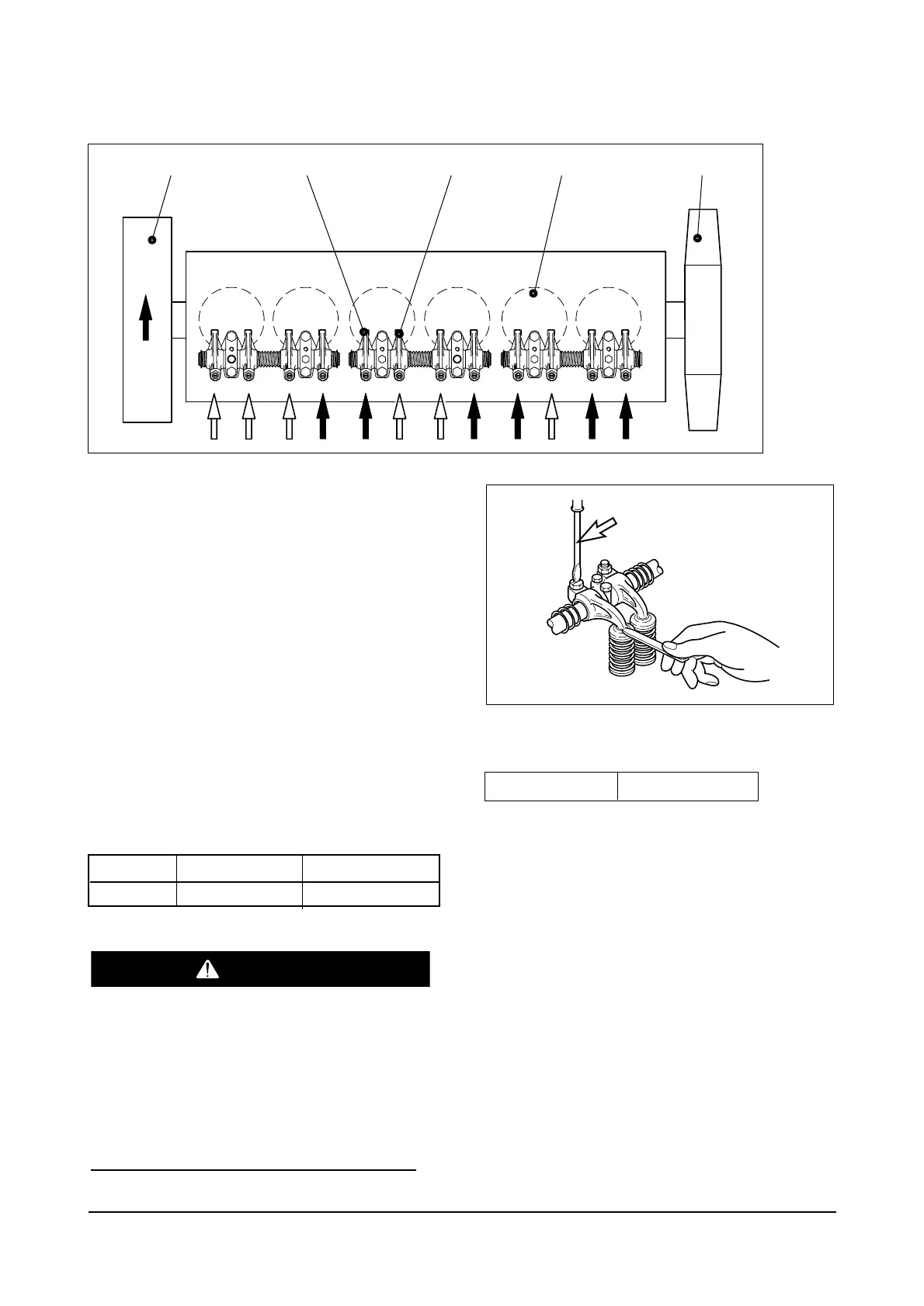

c. To adjust the clearance, loosen the locknuts of

rocker arm adjusting screws and push the feeler

gauge of specified value between a rocker arm

and a valve stem (to measure the clearance of the

valve and rocker arm contacting part) and adjust

the clearance with adjusting screw respectively

and then tighten with the lock nut.

d. As for the valve clearance, adjust it when in cold.

a. Crankshaft revolution is done by hands with-

out using a starting motor.

b. Turn it to the direction of engine rotation, but

do not use the installing bolts at the turn.

c. The cylinder no. and the order of intake and

exhaust can be determined from the crank

shaft pulley.

e. Adjust valve clearance with a feeler gauge and

tighten the fixing nuts to specified torque.

EA8M3007

Valve clearance adjust

WARNING

63

123456

Intake valve Exhaust valve Cylinder no. Cooling fanFlywheel

Model Intake valve Exhaust valve

DE08TS 0.3 mm 0.3 mm

Torque 5.0 kg

•

m

Loading...

Loading...