G643 (E) Service Manual Chapter 3. Engine Mechanical System 73

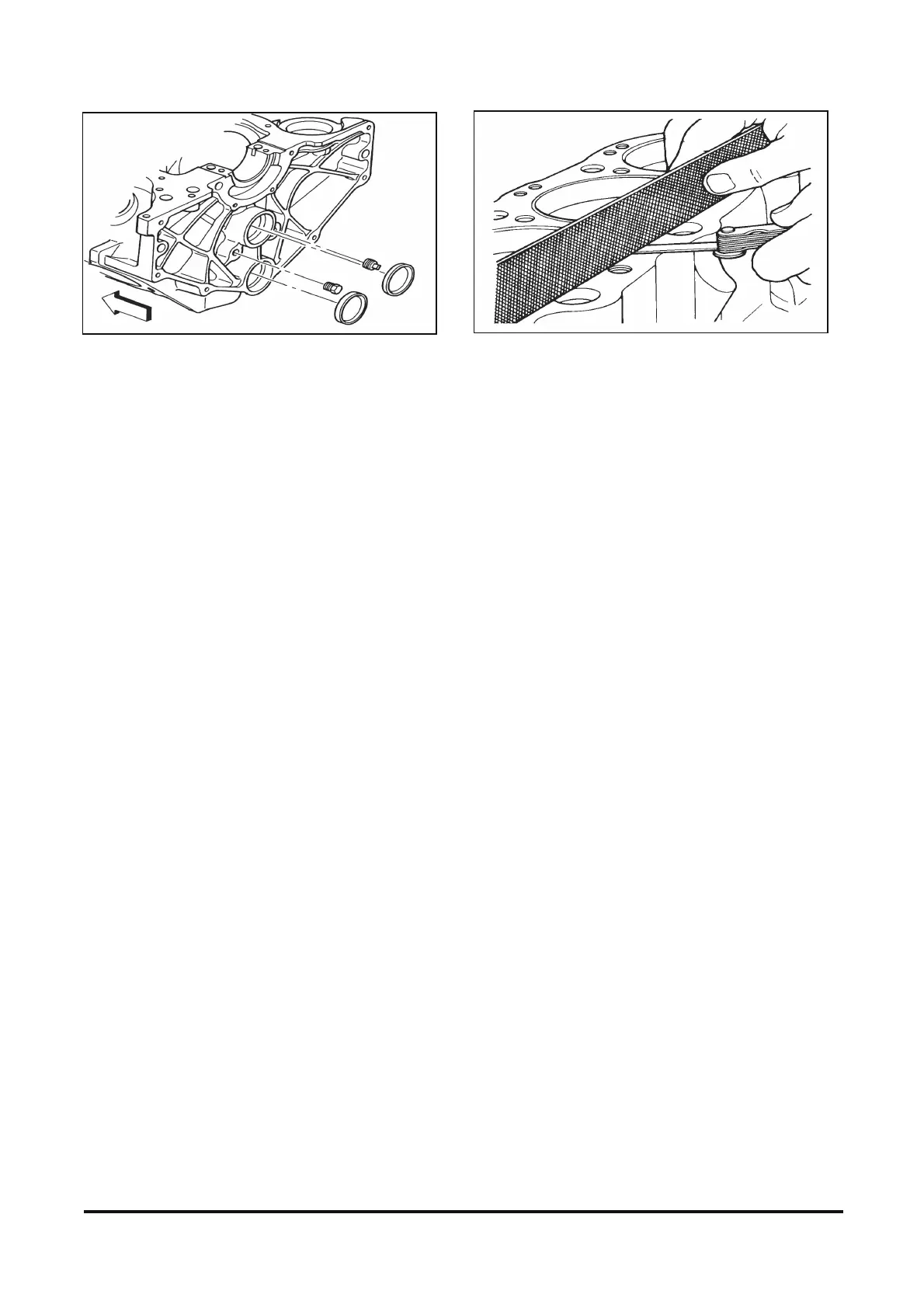

Figure 12-24 Rear Cylinder Block Oil Gallery Plugs

Clean

• Sealing material from mating surfaces.

• Boil cylinder block in caustic solution. Flush with

clean water or steam.

• Cylinder bores.

• Threaded holes.

• Oil galleries and passages.

• Scale deposits from coolant passages.

• Spray or wipe cylinder bores and machined

surfaces with engine oil.

Inspect

• All expansion plugs for lack of fit or leakage.

• Valve lifter bores for deep scratches and deposits.

• Cracks in the block.

- Cylinder walls.

- Coolant jackets.

- Engine mount bosses.

- Main bearing webs.

• Main bearing bores and caps.

- All main bearing bores should be rounded and

uniform in ID at all of the bearing supports.

- The area were the main bearing inserts contact

the main bearing bore should be smooth.

- If a main bearing cap is found to be damaged,

replace the cap and line-bore the block.

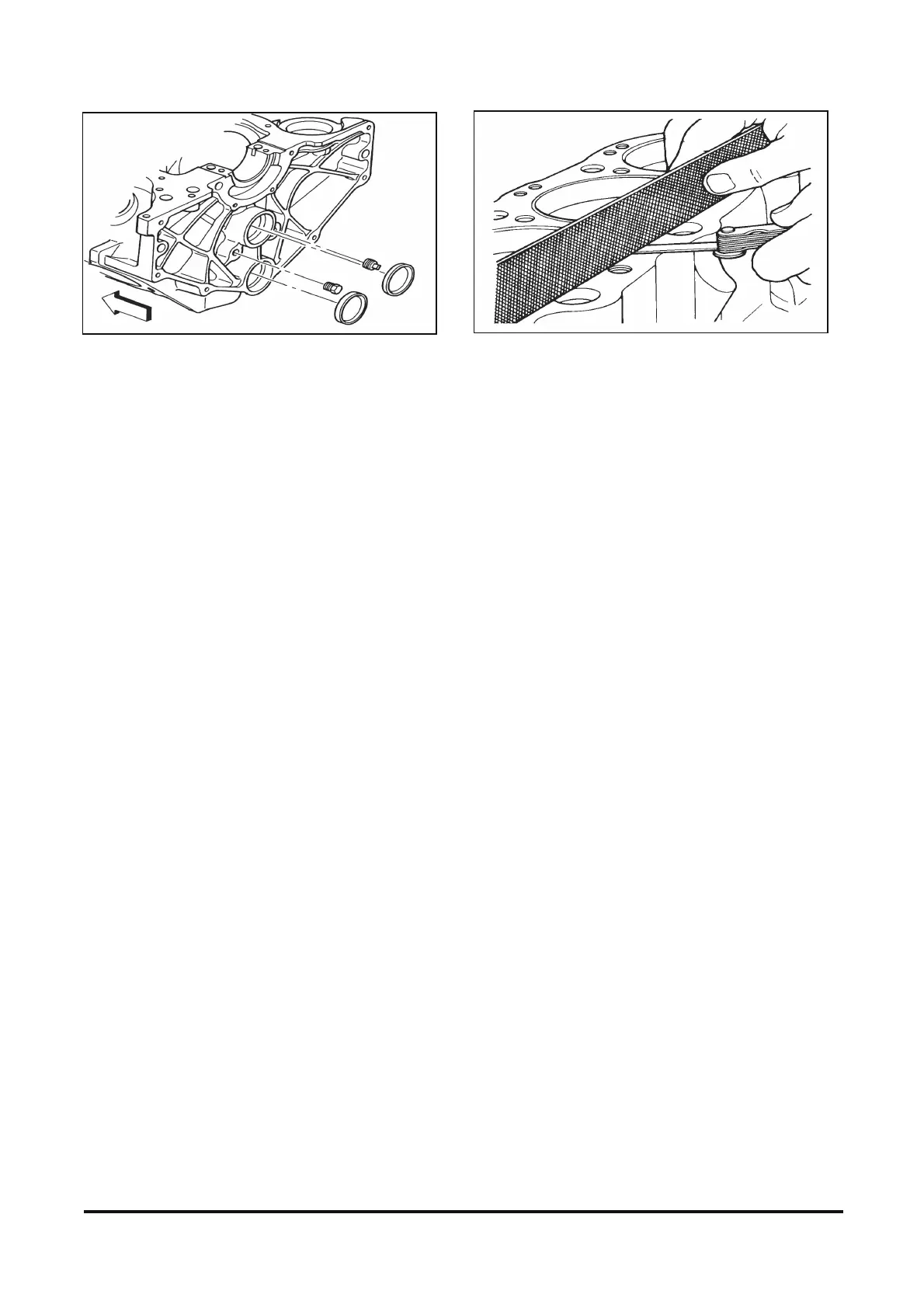

• Cylinder head mounting surface for flatness,

using a precision straightedge and feeler gage

(figure 12-25).

- Set the straightedge on the sealing surface to

be inspected.

- Take the feeler gage and at various locations,

check the gap between the straightedge and

the sealing surface.

Figure 12-25 Measuring Cylinder Block Surface Flatness

- If the gap is greater than 0.05 mm (0.002 in.)

within 152 mm (6 in.) at any sealing location,

the block must be replaced.

- If the gap is found to be less than 0.05 mm

(0.002 in.) at any sealing location and a cause

for leakage is suspected, then the minor

irregularities may be carefully machined from

the block.

• Oil pan, timing cover, and intake manifold

mounting surfaces for nicks. Minor irregularities

may be cleaned up with a flat file.

Cylinder Bore

Inspect

• Cylinder bores for scoring or other damage.

• Cylinder bore taper and out-of-round.

Measuring Cylinder Bore Taper and Out-

Of-Round

Figure 12-26

Tool Required:

J 8087 Cylinder Bore Gage (or equivalent)

IMPORTANT: If one or more cylinder bores are

rough, scored or worn beyond limits, it will be

necessary to smooth or true up such bores to fit

new pistons. No attempt should be made to cut

down oversize pistons to fit cylinder bores as

this will destroy the surface treatment and affect

the weight. The smallest possible oversize

pistons should be used and the cylinder bores

should be honed to size for proper clearances.

Loading...

Loading...