G643 (E) Service Manual Chapter 3. Engine Mechanical System 78

Piston Selection

Figures 12-34 and 12-35

1. Check the used piston to cylinder bore clearance.

Measure

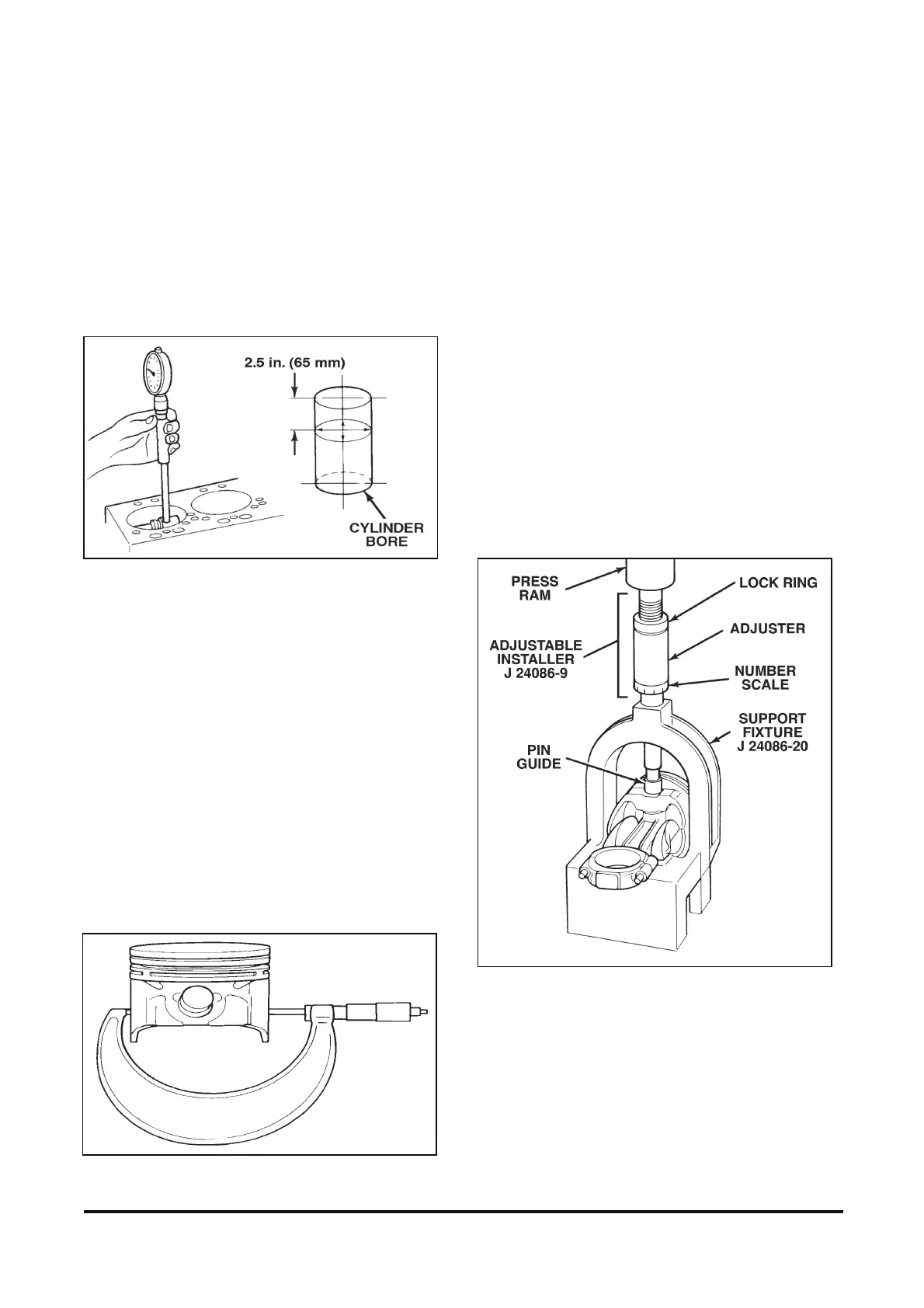

A. Cylinder bore diameter. Use a telescoping

bore gage, located 65 mm (2.5 in.) below the

top of the cylinder bore (figure 12-34).

Figure 12-34 Measuring Cylinder Bore Diameter

B. Piston diameter. Measure the piston skirt at a

right angle to the piston pin, at the centerline

of the piston pin (figure 12-35).

C. Subtract the piston diameter from the cylinder

bore diameter to determine piston to bore

clearance.

D. Refer to “Specifications” in the proper Section.

Determine if the piston clearance is in the

acceptable range.

2. If the used piston is not acceptable, determine if

a new piston will fit the cylinder bore.

3. If a new piston does not bring the clearance

within tolerances, the cylinder bore must be

reconditioned.

4. Mark the piston to identify the cylinder for which

it was fitted.

Figure 12-35 Measuring Piston Skirt

Piston Assembly

Assembling the Piston and Connecting Rod

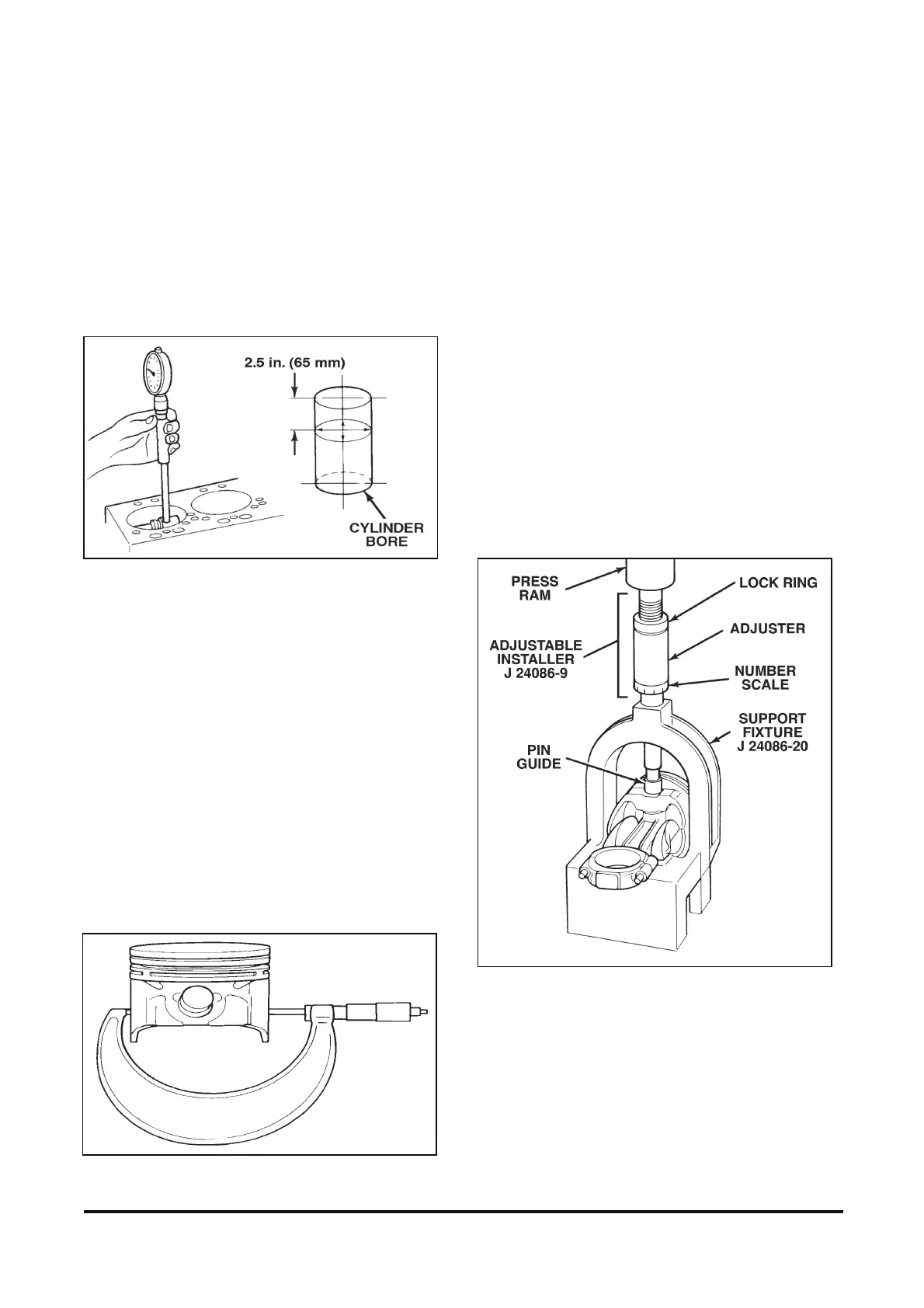

Figure 12-36

Tool Required:

J 24086-B Piston Pin Remover and Installer Set

Install or Connect

1. Piston and connecting rod.

A. The valve cutouts in the piston crown must be

opposite the connecting rod bearing tangs.

B. Lubricate the piston pin holes in the piston

and connecting rod with engine oil.

C. Install the pin guide to hold the piston and

connecting rod together. Be sure to use the

proper pin guide. Refer to the instructions

supplied with the tool.

Figure 12-36 Installing Piston Pin

2. Piston pin.

A. Insert the piston pin into the piston pin hole.

B. Place the assembly on the support fixture.

Loading...

Loading...