G643 (E) Service Manual Chapter 3. Engine Mechanical System 85

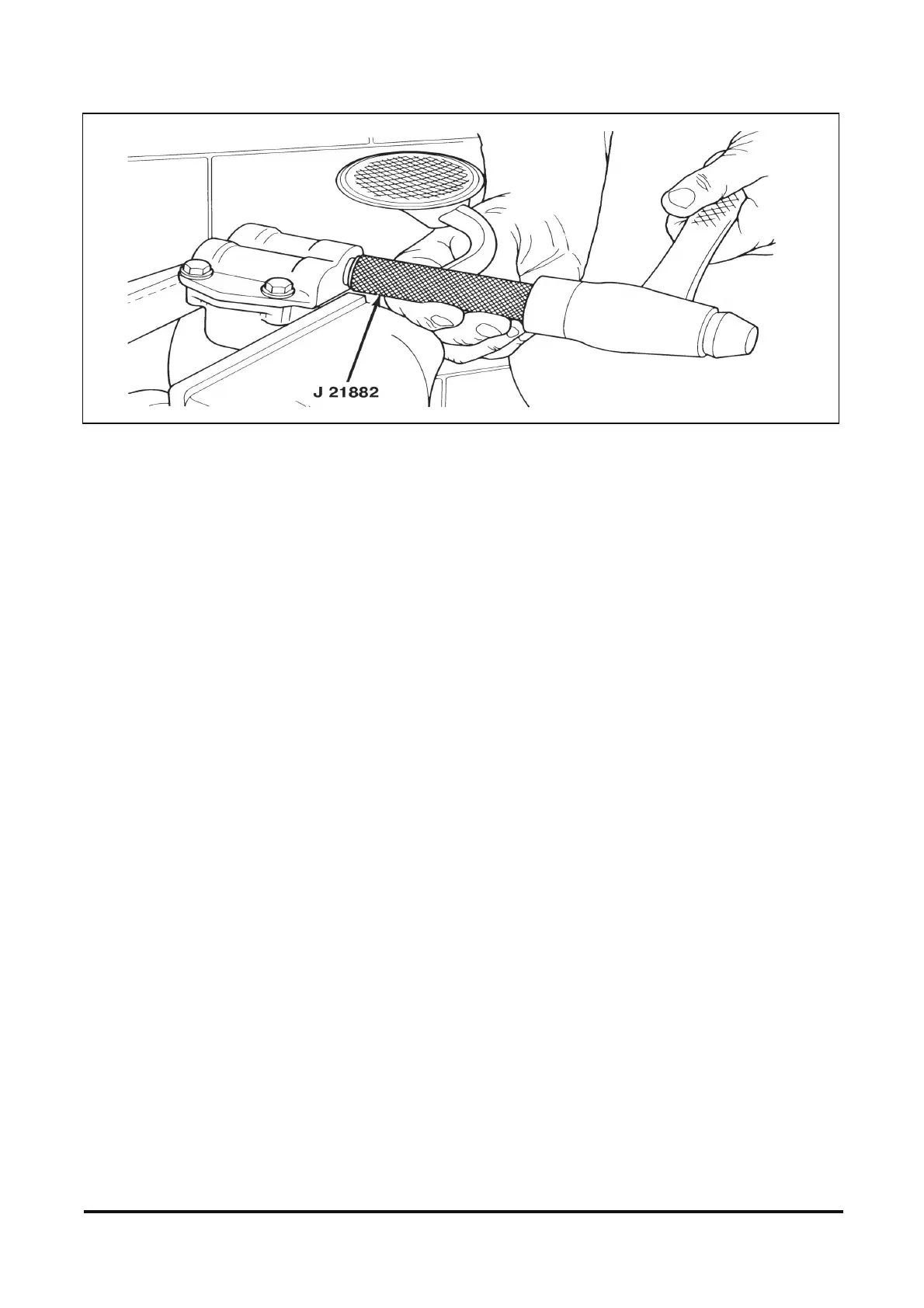

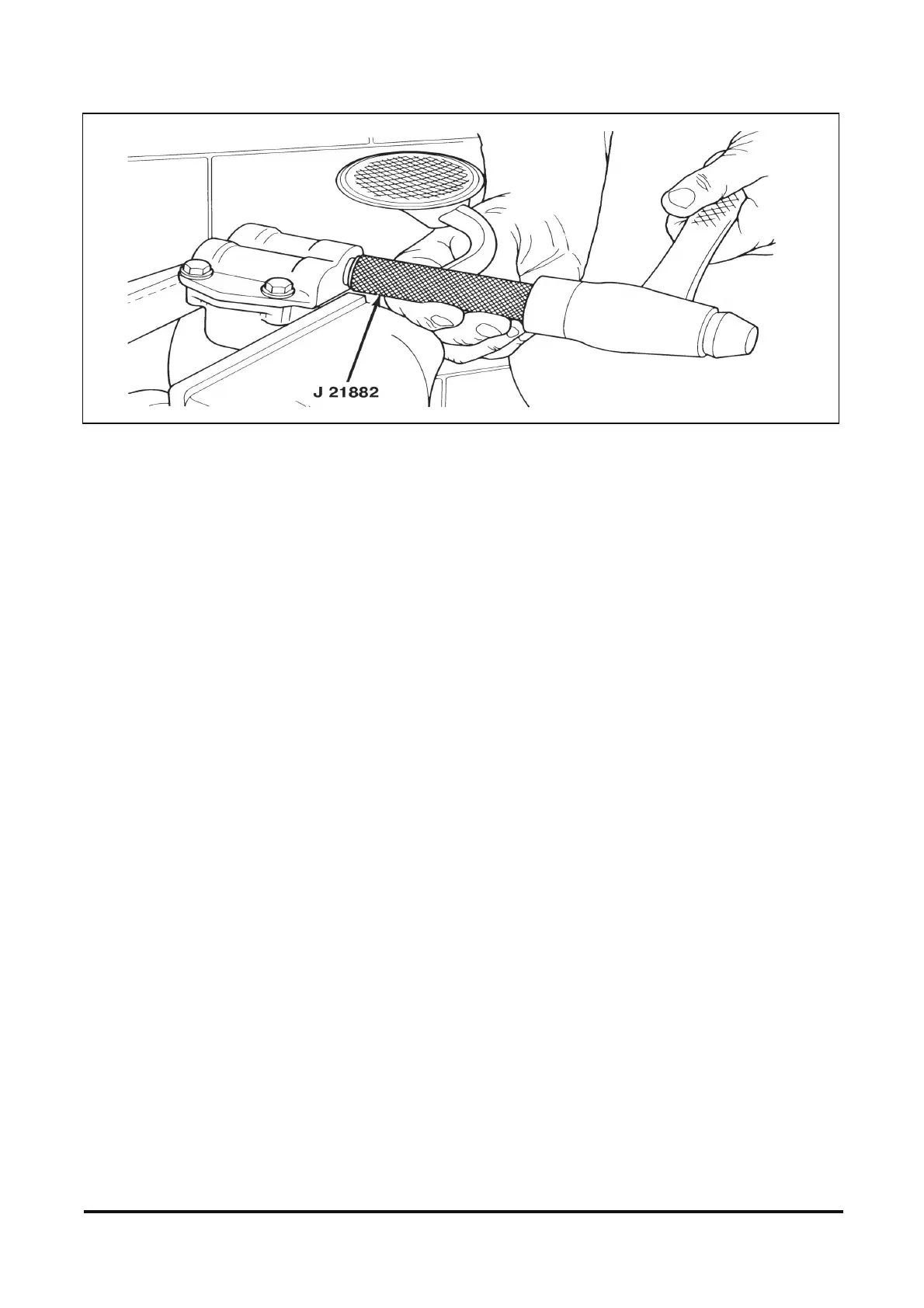

Figure 12-47 Installing Oil Pump Screen

Inspect

• With the shaft extension installed on the pump,

turn the drive shaft by hand to check for smooth

operation.

NOTICE: Be careful of twisting, shearing, or

collapsing the pipe when installing it to the pump. A

damaged pipe can cause lack of lubrication and

engine failure.

8. Pickup screen and pipe.

A. If the pickup screen and pipe assembly was

removed, it should be replaced with a new

part. Loss of press fit condition could result in

an air leak and loss of oil pressure.

B. Mount the oil pump in a soft-jawed vise.

C. Apply sealer to the end of the pipe.

D. Tap the pickup screen and pipe into place,

using J 21882 and a hammer.

E. The pump screen must be parallel with the

bottom of the oil pan when installed.

9. Oil pump drive shaft and connector.

Valve Train Components

IMPORTANT: Store all reusable components in

an exact order, so they may be reassembled in

the same position from which they were

removed.

Clean

• All parts in clean solvent and dry them with

compressed air.

• Make sure the oil passages through the pushrods

are clear.

Inspect

• Valve rocker arms and balls at their mating

surfaces. These surfaces should be free from

wear or damage.

• Valve rocker arm areas that contact the valve

stems and the socket areas that contact the ends

of the pushrods. These areas should be free of

wear or damage.

• Valve rocker arm nuts.

• Valve pushrod ends for scoring, roughness, or

bends.

- Roll the pushrod on a flat surface to determine

its straightness. If the rod is bent, the rod will

not roll freely. Replace if necessary.

Loading...

Loading...