G643 (E) Service Manual Chapter 3. Engine Mechanical System 93

Crankshaft Runout

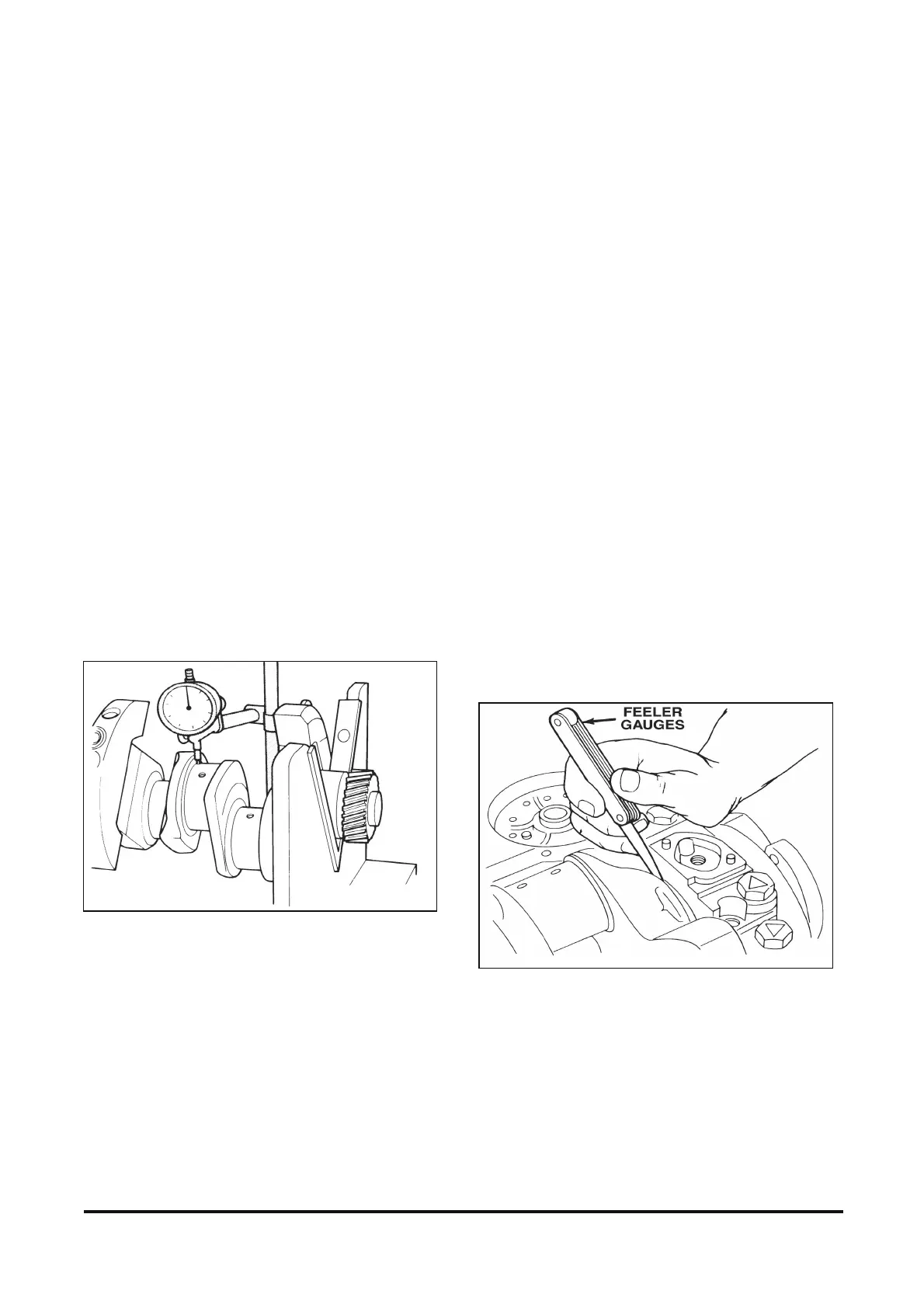

Figure 12-64

Measure

Tool Required:

J 7872 Magnetic Base Dial Indicator

1. Crankshaft run-out.

A. Mount the crankshaft in V-blocks at crankshaft

journals 1 and 4.

B. Use a dial indicator as shown (figure 12-64).

C. If the main journals are misaligned, the

crankshaft is bent and must be replaced. The

main bearings must also be replaced at the

same time.

D. Grind or replace the crankshaft if necessary.

In general, the lower inserts (except the # 1

bearing) show the greatest wear and distress

from fatigue. Upon inspection, if a lower insert

is suitable for reuse, it can be assumed that

the upper insert is also satisfactory. If a lower

insert shows evidence of wear or damage,

both the upper and lower inserts must be

replaced.

Figure 12-64 Measuring Crankshaft Runout

Crankshaft End Play

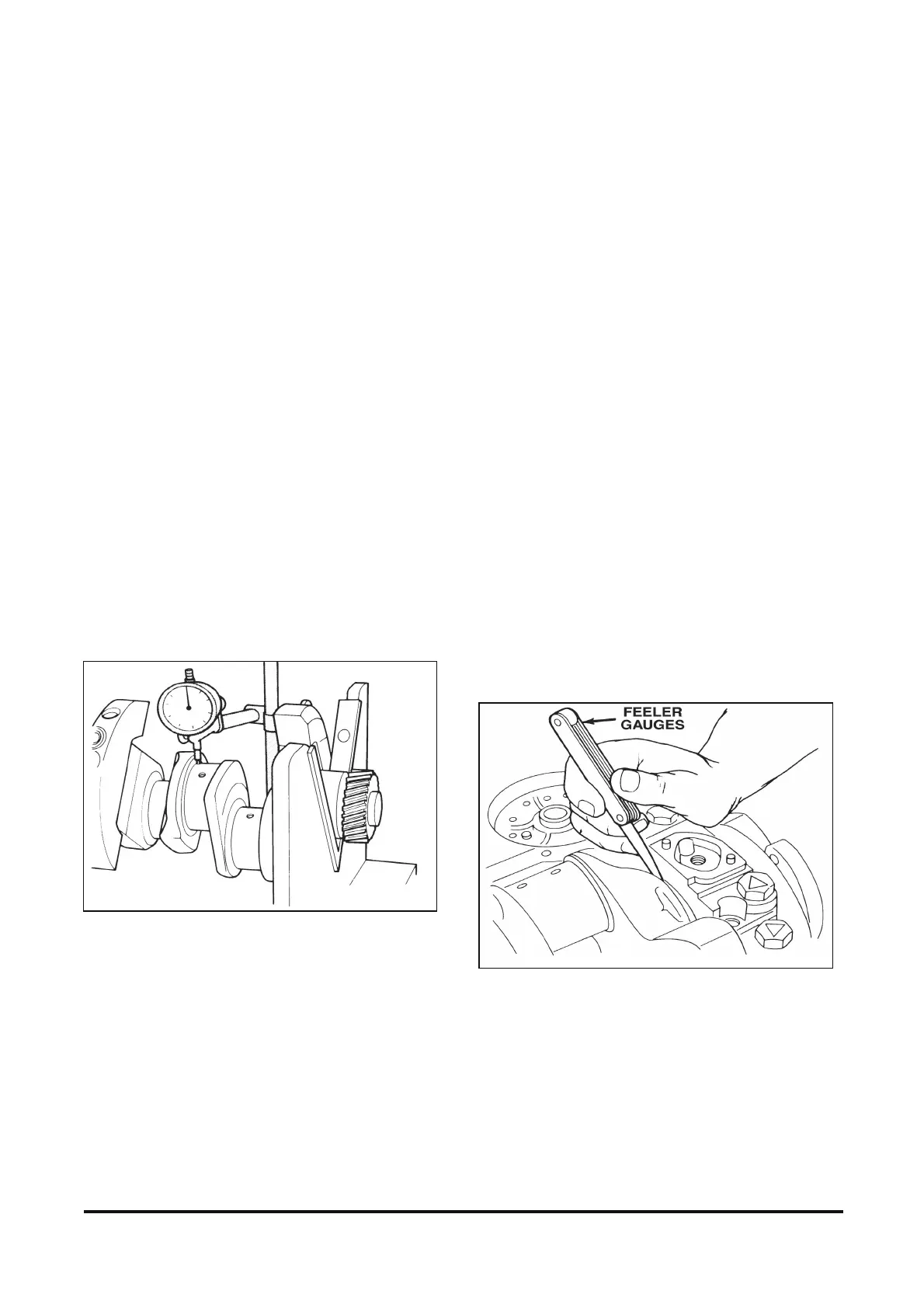

Figure 12-65

Measure

• Crankshaft end play as follows:

a. Install crankshaft bearings, crankshaft, caps,

and bolts.

b. Tighten bolts to specification.

c. Firmly thrust end of the crankshaft first

rearward then forward. This will line up the

rear main bearing and crankshaft thrust

surfaces.

d. With the crankshaft wedged forward, measure

at the front end of the rear main bearing with a

feeler gage (figure 12-65). Refer to

“Specifications”.

IMPORTANT: If correct end play cannot be

obtained, be certain that the correct size rear

main bearing has been installed. Some

production engines may use crankshaft

bearings that are wider across the thrust faces

than standard size bearings. Refer to

“Specifications” for available bearing sizes.

Inspect

• Crankshaft for binding. Turn crankshaft to check

for binding. If the crankshaft does not turn freely,

loosen the crankshaft bearing bolts, one pair at a

time until the tight bearing is located. Burrs on the

bearing cap, foreign matter between the bearing

and the block or the bearing cap, or a faulty

bearing could cause a lack of clearance at the

bearing.

Figure 12-65 Measuring Crankshaft End Play

Connecting Rod Bearings

Follow all procedures outlined for crankshaft bearing

cleaning, inspection, and measurement. Refer to

“Specifications”.

Loading...

Loading...