G643 (E) Service Manual Chapter 3. Engine Mechanical System 81

Camshaft Bearings

Camshaft Bearing Removal

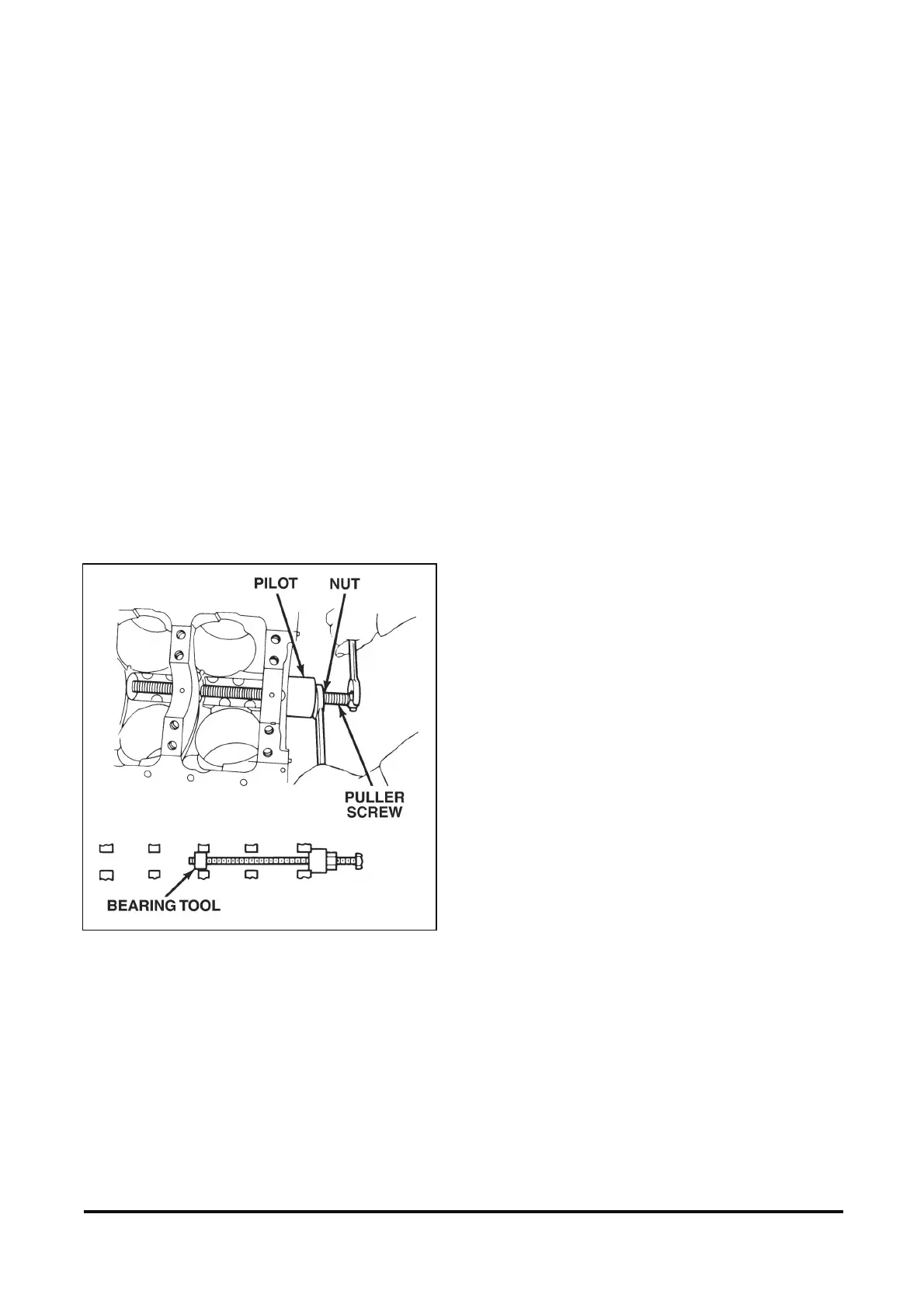

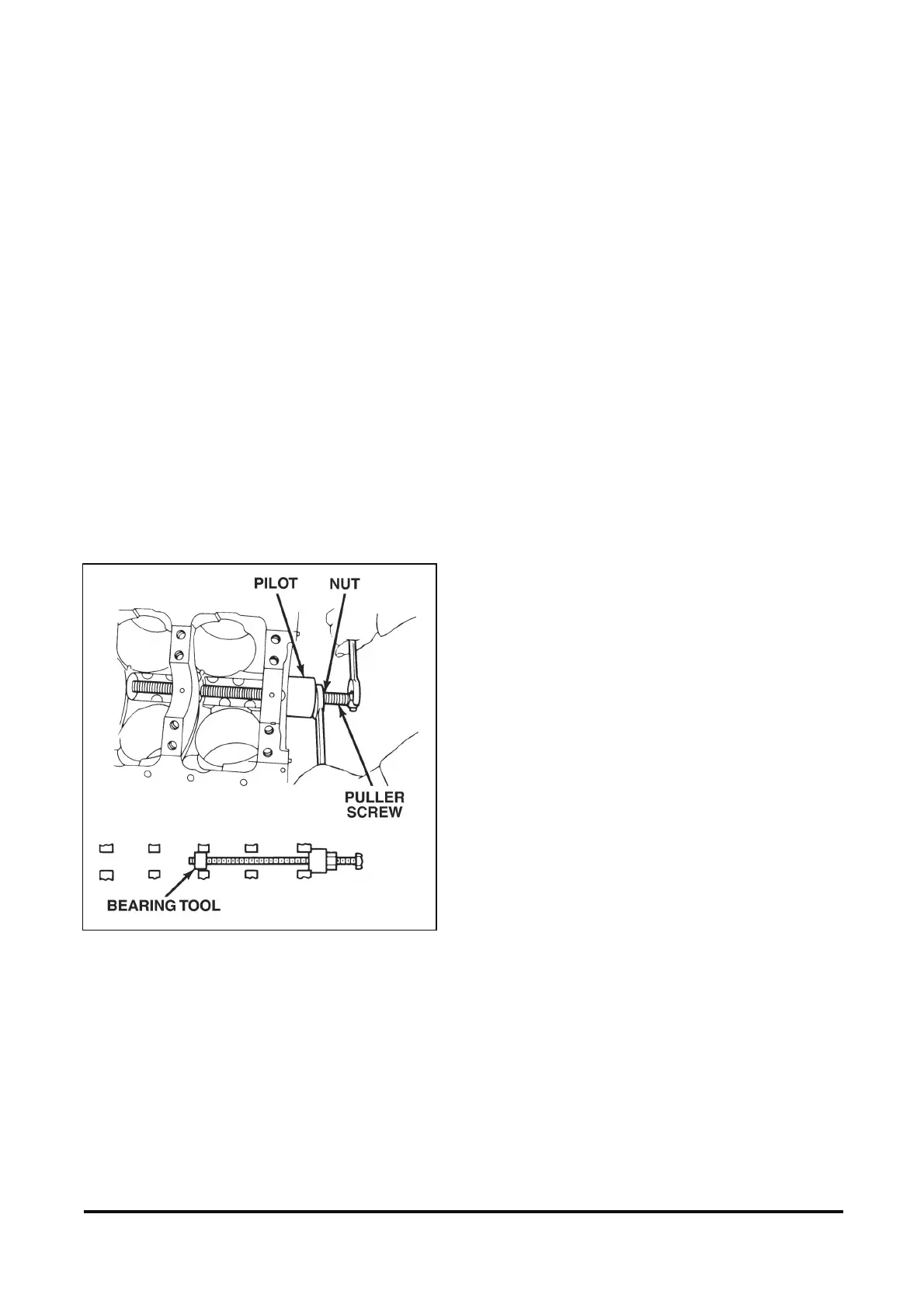

Figure 12-43

Tool Required:

• J 33049 Camshaft Bearing Remover and

Installer

Remove or Disconnect

1. Rear camshaft plug.

2. All camshaft bearings. Use J 33049 (figure 12-

43).

A. Insert the tool with the correct collet into the

camshaft bearing you want to replace.

B. Turn the tool until the collet has tightened in

the bearing.

Figure 12-43 Removing / Installing Camshaft Bearings

C. Push the center cone against the block and

into the bearing bore to center the tool.

D. Drive the bearing from the block.

E. Repeat this procedure to remove the

remaining inner camshaft bearings. Note that

the rear bearing must be removed from the

front of the block and the front bearing from

the rear. This allows the tool to remain

centered.

Cleaning and Inspection

Clean

• Camshaft bearing bores in the block.

Inspect

• Camshaft bearings for scratches, pits, or loose fit

in their bores. Replace the camshaft bearings if

necessary.

• Camshaft lobes and journals for scratches, pitting,

scoring, and wear. Minor irregularities may be

cleaned up with emery cloth.

Camshaft Bearing Installation

Figure 12-43

Install or Connect

Tool Required:

• J 33049 Camshaft Bearing Remover and

Installer

NOTICE: The outer camshaft bearings must be

installed first. These bearings serve as guides for

the pilot, and help center the inner bearings during

the installation process.

NOTICE: Make sure to fit the correct cam bearing

into the bore. The cam bearing bores vary in size.

1. Rear camshaft bearings. Drive the bearings into

place using J 33049 from front of engine (figure

12-43).

IMPORTANT: Make sure the camshaft bearing

hole (or holes) align with the oil hole (or holes)

in the block. On some engines, the oil holes may

be difficult to see. If so, use a piece of 2 mm rod

to check alignment.

2. Front camshaft bearing using tool J 33049

(figure 12-43).

IMPORTANT: Make sure the camshaft bearing

hole (or holes) align with the oil hole (or holes)

in the block.

3. Inner camshaft bearings using tool J 33049.

Reverse of removal procedure.

4. Camshaft rear plug.

Loading...

Loading...