16 Dräger X-dock 5300/6300/6600

Use

b. Select Check config. and Set config. whether to

check the configuration. If the configuration does not

match the template, the gas monitor will be

automatically reconfigured according to the

configuration template.

5Use

5.1 Conducting a visual inspection

A visual inspection of the instruments must be conducted

every time before being inserted into the station.

1. Check that the housing, external filters and the nameplates

are intact.

2. Check the battery contacts and sensor inputs for dirt.

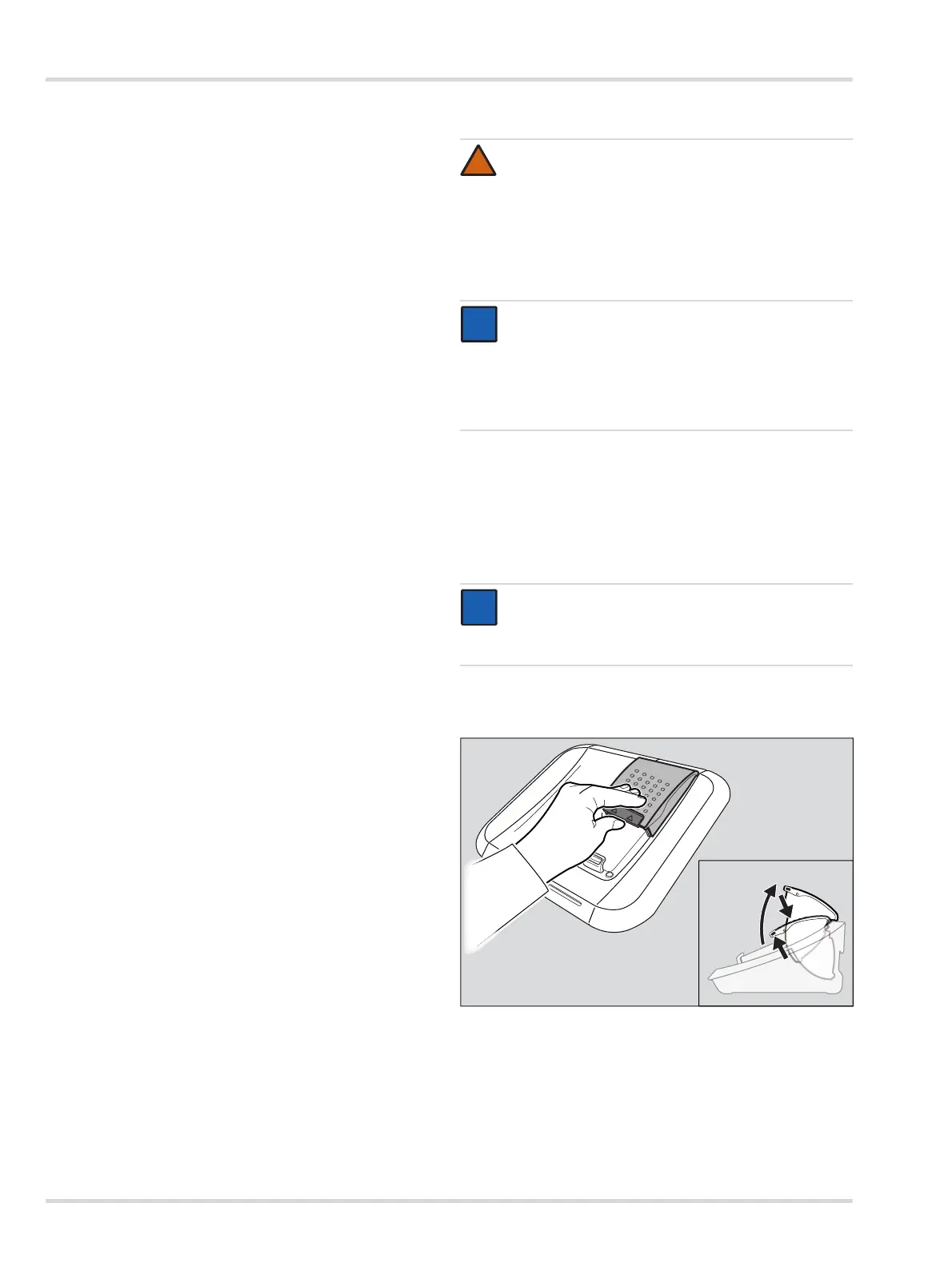

5.2 Inserting or removing the gas measuring

device into or from a module

To insert the instrument in the module:

1. If necessary, push the lock up slightly and open the module

cover upwards.

2. Place the instrument in the corresponding module.

3. Close the module flap.

The instrument will be detected automatically.

WARNING

A defective pressure reducer on the gas cylinder can

lead to increased pressure in the station. The gas

hoses may loosen as a result and gas may escape.

Health hazard! Test gas must not be inhaled. Observe

the hazard warnings in the relevant Safety Data

Sheets. Provide venting into a fume cupboard

or outside the building.

NOTICE

To prevent loss of gas, Dräger recommends closing

the gas cylinders when the station is left unattended for

long periods.

Adjustment may not be possible due to instrument and

channel errors.

NOTICE

Instruments that did not pass visual inspection must

not be inserted into the station. Otherwise the test

cannot be correctly assessed in its entirety.

!

i

i

i

i

00233286.eps

1

2

Loading...

Loading...