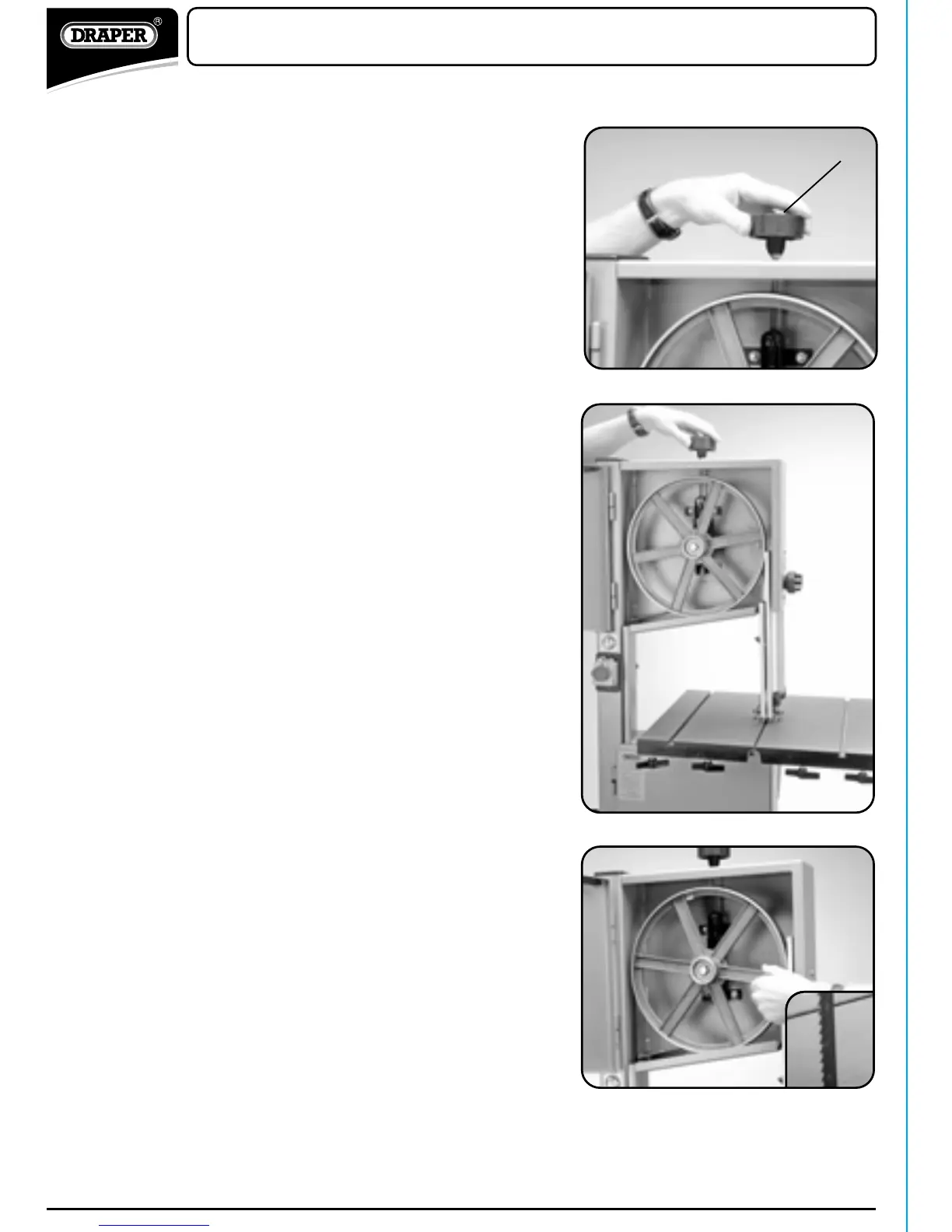

- TENSIONING THE BLADE (Fig.18.):

Turn the blade tensioning knob7clockwise until the

blade is tensioned. The blade tension can be checked

by pushing down on the blade midway between the

two wheels. When the tension is correct the blade

should move slightly with firm finger pressure.

NOTE: Do not overtighten the blade. Too much tension

may cause blade breakage. Too little tension may cause

the blade to slip on the wheels.

7

FIG.18

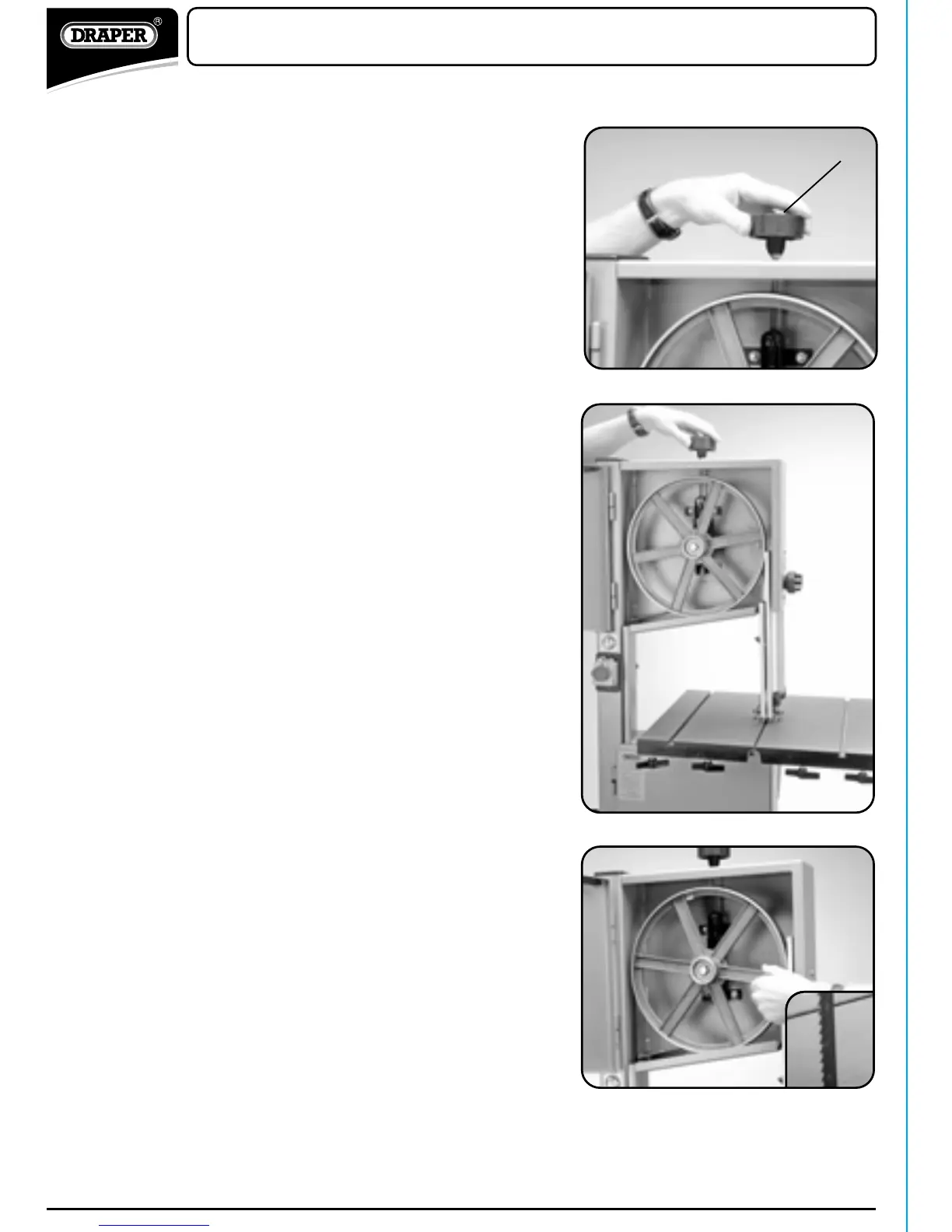

CHANGING AND SETTING THE SAW BLADE:

(Fig.19-20.)

To change the saw band, remove the graduated rip

fence rail from the table. Slacken the blade tension with

the quick release lever. Remove the blade carefully.

Fit the new saw band carefully [with the teeth facing

down]. When the saw band is located correctly through

the guide and is sat centrally on the upper and lower

wheels, operate the tension quick release lever to re

engage the tension.

As the tension has been released during this process,

the tracking should be checked and adjusted. The blade

should run in the centre of the rubber lined bandsaw

wheels otherwise it may jump off.

FIG.20

FIG.19

OPERATION AND USE

- WARNING!

Select a blade suitable for the intended material and use

on this machine. Read the safety instructions.

Loading...

Loading...