29

SETUP

• If using hard duct, install flexible

connection between Dremel LC40 laser

cutter and any hard duct to isolate

vibration from duct and prevent duct

damage. Up to six inches of provided

Exhaust Hose may be used to create

flexible connection.

• 90-degree elbows must be at least 20

inches away from External Booster Fan.

If you are unsure how to setup the exhaust

duct, consult an HVAC professional.

4. Secure booster fan according to

manufacturer’s instructions. Installation

of the booster fan should be as close to

the discharge point as possible to

minimize leakage into the space from

positively pressurized ductwork.

5. Seal all seams and connections with

building code approved sealant or duct

tape.

Setting up Exhaust Management Method

C or D: Filtration Units

Exhaust management methods C and D

use a filtration unit (not supplied) to filter

the Dremel LC40 Laser Cutter exhaust.

When selecting a filtration unit be sure it is

suitable for use with laser cutters/

engravers. The filtration unit should be

Underwriters Laboratory listed. When

using an external filtration unit be sure to

choose correct ventilation option on the

Touch Screen during the Dremel LC40

Laser Cutter startup sequence. Choose a

well-ventilated area to set-up the Dremel

LC40 Laser Cutter and filtration unit.

Follow the manufacturer’s instructions for

changing filter(s) in filtration unit.

Items supplied with Dremel LC40 Laser

Cutter: (1) 10 ft. Exhaust Hose & (2) Hose

Clamps.

• Additional Items needed: Building code

approved sealant or duct tape, filtration

unit.

1. Set up filtration unit according to

manufacturer’s instructions and relevant

building and fire codes.

2. Supplied 10’ Exhaust Hose and Hose

Clamps may be used if compatible with

selected filtration unit.

3. Seal all seams and connections with

building code approved sealant or duct

tape.

Requirements for Exhaust Management

Method E: Commercial/Industrial

Mechanical Exhaust System

Connection of Dremel LC40 Laser Cutter

to a Commercial/Industrial Mechanical

Exhaust System should only be performed

by a trained HVAC professional. Exhaust

must be discharged outdoors and

installation must comply with all codes and

regulations for hazardous or noxious

exhaust ventilation systems. The design

flow rate of exhaust from the Dremel LC40

Laser Cutter must be a minimum of 90

cubic feet per minute (CFM). When using a

Commercial/Industrial Mechanical Exhaust

System be sure to choose correct

ventilation opt When using a Commercial/

Industrial Mechanical Exhaust System be

sure to choose correct ventilation option

on the Touch Screen during the Dremel

LC40 Laser Cutter startup sequence.

= Do not use for

Dremel LC40 Laser

Cutter.

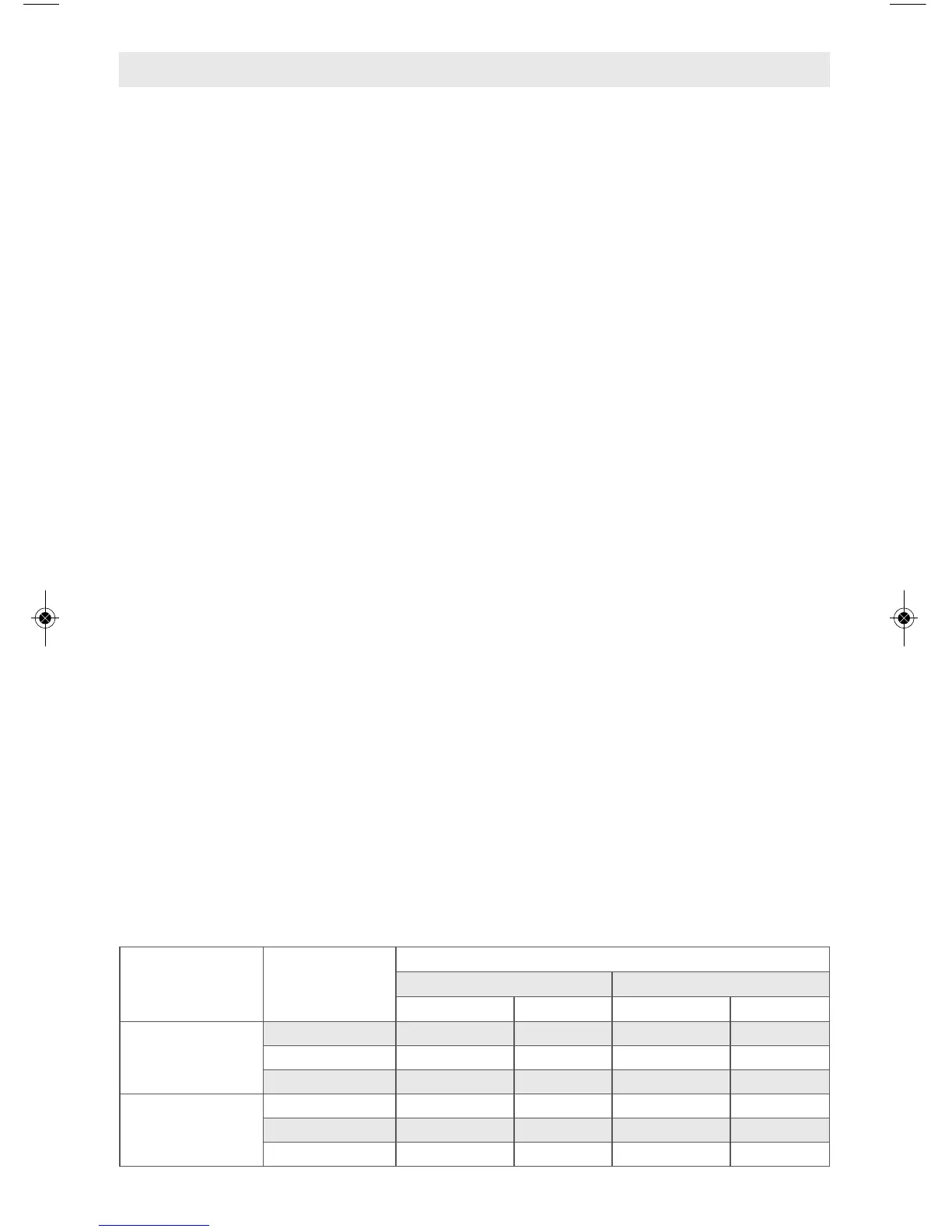

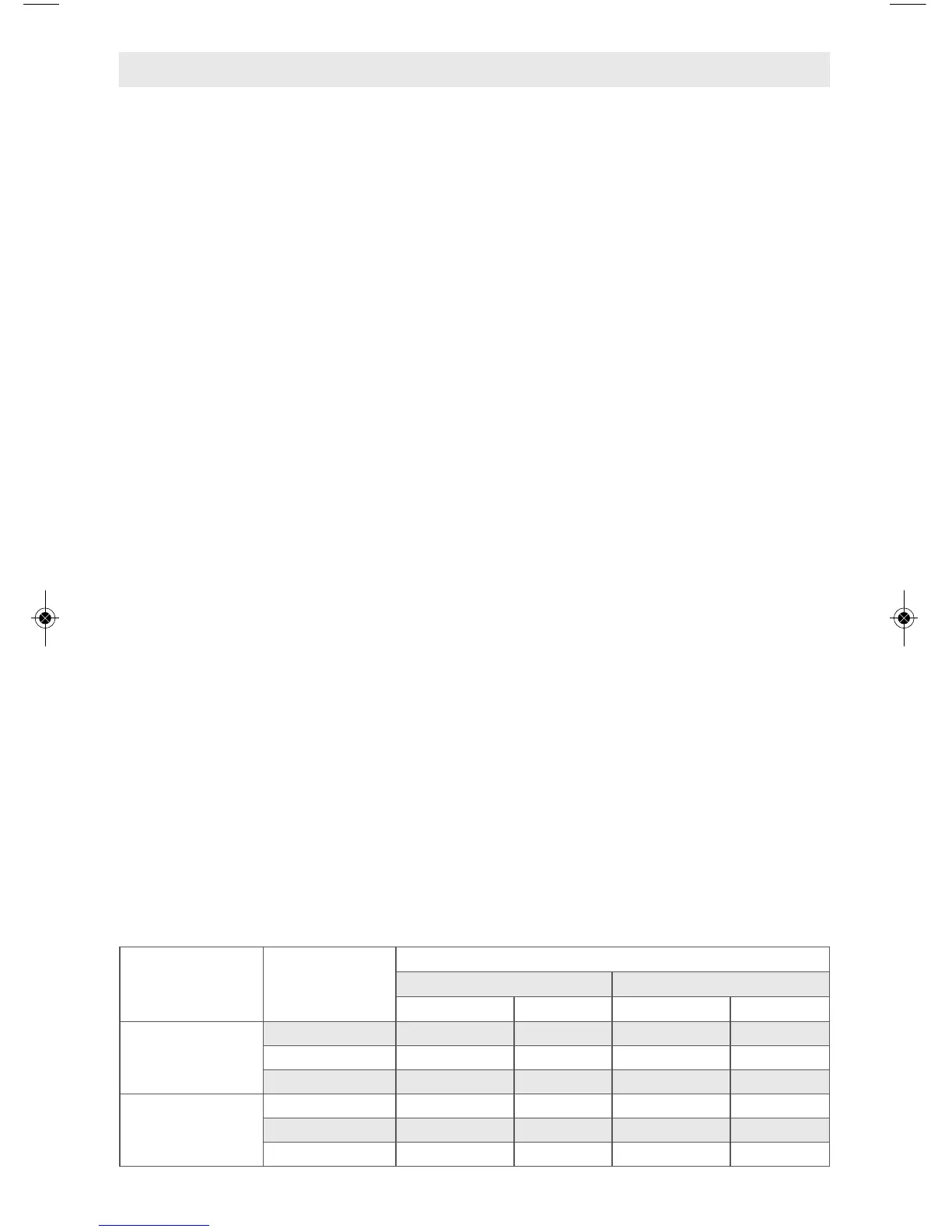

Number of

Bends/Elbows

Allowable Duct Length (feet)

4" Diameter Duct 5" Diameter Duct

Flexible Duct Hard Duct Flexible Duct Hard Duct

Bend radius

at least 2*D

2 33 92 155 290

3 13 72 135 270

4

52 115 250

Bend radius

at least 1.5*D

2 13 72 135 270

3

42 105 240

4

12 75 210

Table 4: Allowable duct length and number of bends/elbows

Loading...

Loading...