G E T T I N G S T A R T E D

4

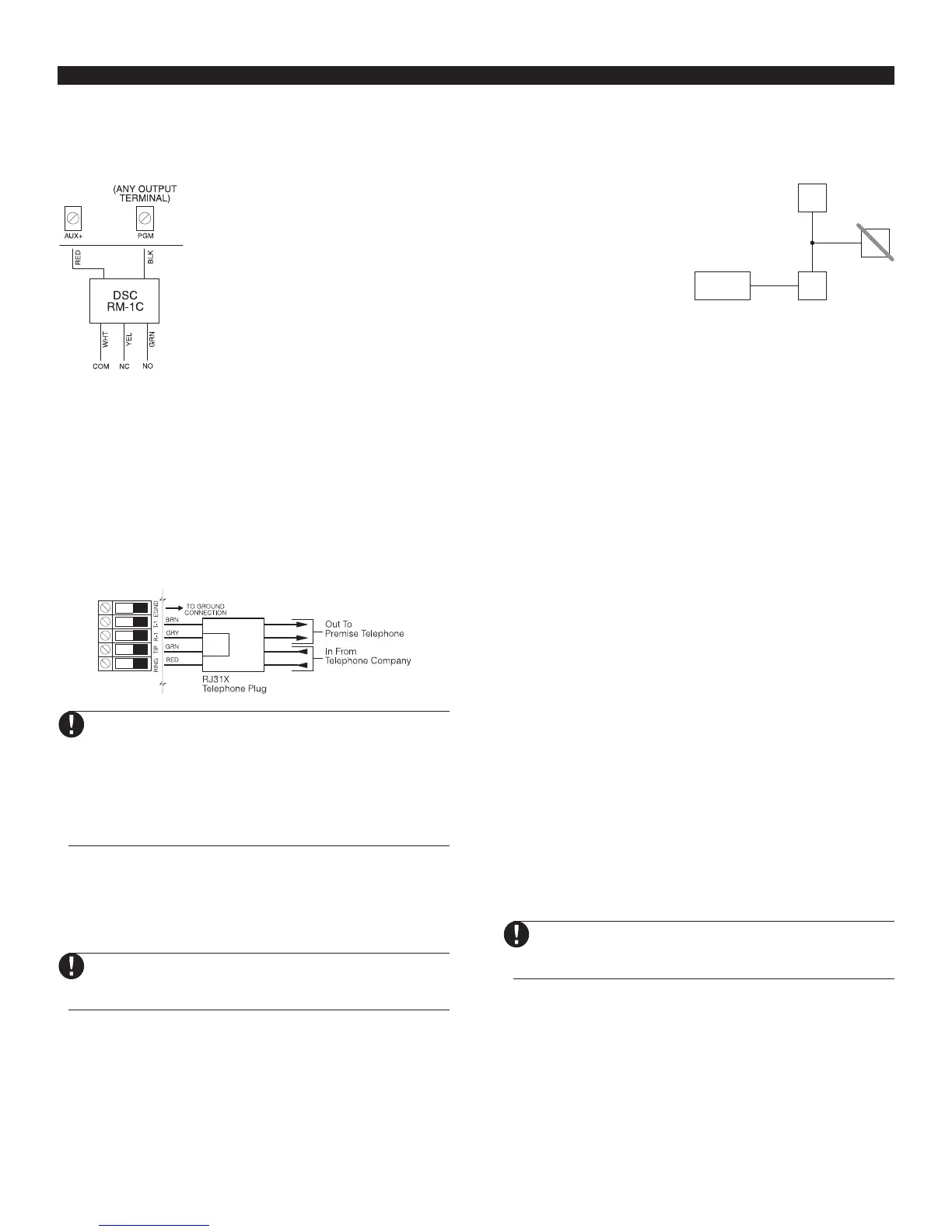

Programmable Output Terminals – PGM1 and

PGM2

Each PGM output is designed so that when activated by the

panel, the terminal will switch to ground.

PGM1 can sink up to 300mA of current.

Connect the positive side of the LED or

buzzer to AUX+, the negative side to

PGM1. If more than 300 mA of current are

required, a relay must be used. Please

study PGM wiring in the accompanying

diagram.

PGM2 operates similarly to PGM1.

However, PGM2 can only sink up to 50mA

of current. For a list of the programmable

output options, please see Section 5.11

“PGM Output Options.”

Zone Input Terminals – Z1 to Z4

Each detection device must be connected to a zone on the

control panel. We suggest that one detection device be

connected to each zone; wiring multiple detection devices to a

single zone, however, is possible. For zone wiring specifics,

please see Section 2.8 (“Zone Wiring”).

Telephone Connection Terminals –

TIP, RING, T-1, R-1

If a telephone line is required for central station communication

or downloading, connect an RJ-31X telephone jack in the

following manner:

For proper operation, no other telephone equipment

should be connected between the control panel and

the telephone company facilities

.

Do not connect the

alarm panel communicator to telephone lines

intended for use with a fax machine. These lines may

incorporate a voice filter which disconnects the line

if anything other than fax signals are detected,

resulting in incomplete transmissions

.

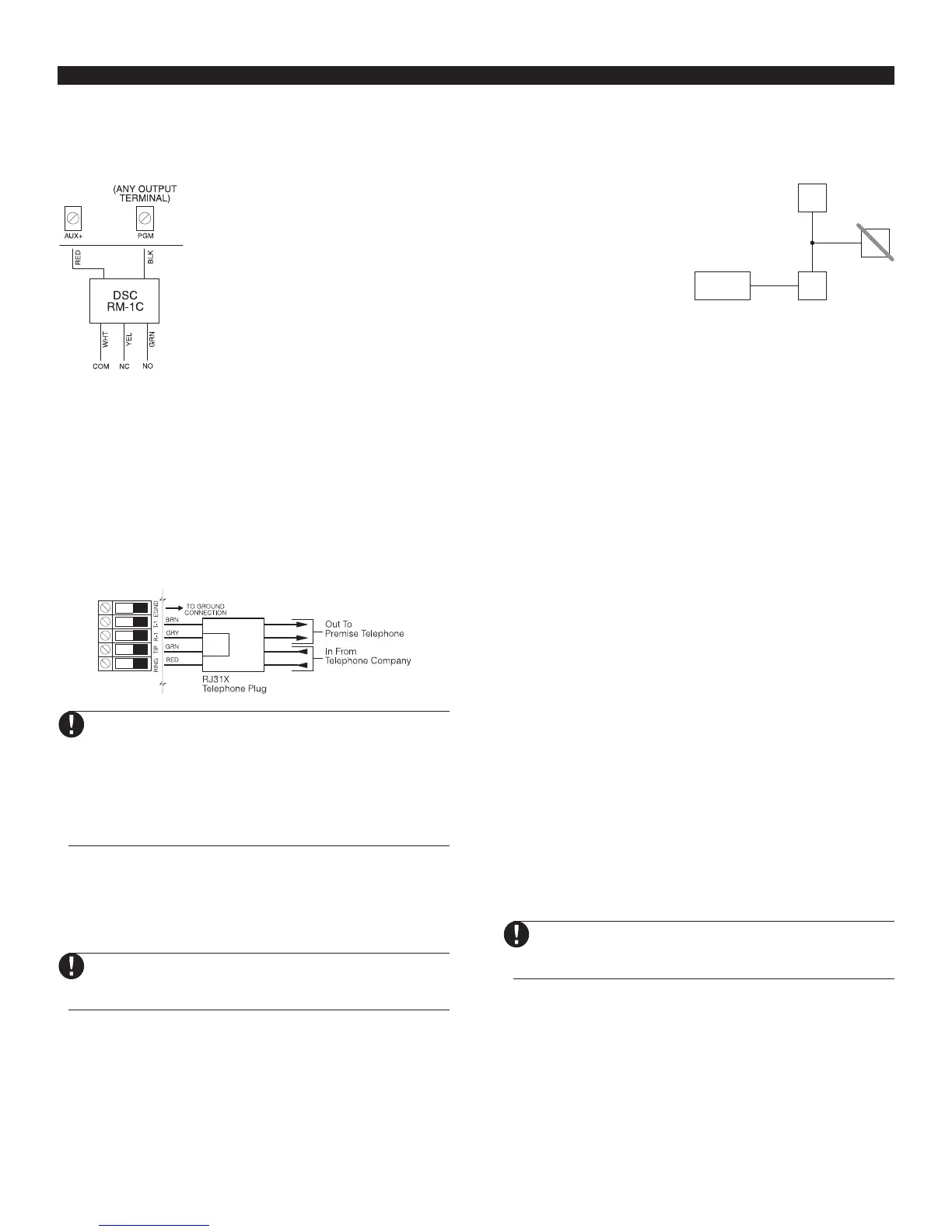

2.3 Keybus Operation and Wiring

The Keybus is used by the panel to communicate with all

connected modules and vice versa. The red (AUX+) and black

(AUX-) terminals are used to provide power, while the yellow

(YEL) and green (GRN) terminals are clock and data respectively.

The four Keybus terminals of the panel must be

connected to the four Keybus terminals or wires

of all modules.

The following restrictions apply to Keybus wiring:

• Keybus should be run in minimum 22 gauge quad (0.5mm);

two pair twist is preferred.

• The modules should be home-run to the panel but can be

connected in series or T-tapped.

• Any module can be connected anywhere along the Keybus. You

do not need to run a separate Keybus wire for keypads, etc.

• No module can be more than 1,000'/305m (in wire length)

from the panel.

• Shielded wire should not be used.

Example of Keybus Wiring

NOTE:

Module (A) is correctly

wired within 1,000'/305m of

wire from the panel.

Module (B) is correctly

wired within 1,000'/305m of

wire from the panel.

Module (C) is NOT wired correctly as it is further than 1,000'/

305m from the panel, in wire distance.

2.4 Current Ratings – Modules and

Accessories

In order for the PC585 system to operate properly, the power output

capabilities of the main control and the expansion devices must not

be exceeded. Use the data presented below to ensure that no part

of the system is overloaded and cannot function properly.

PC585 (12 V

DC)

AUX

+

: ........... 550mA: Subtract the listed rating for each keypad,

expansion module and accessory connected to

AUX

+

or Keybus.

BELL: ...........700mA continuous rating; 3.0A short term.

Available only with standby battery connected.

PC585 Device Ratings (at 12 VDC)

• LCD5500Z Keypad: 75-85mA

• PC1555RKZ Keypad: 75-85mA

• PC5508Z Keypad: 75-85mA

• PC5400 Serial Module: 65mA

• PC5132 Wireless Receiver: 125mA

Other Devices

Please read the manufacturer’s literature carefully to determine

the maximum current requirements for each device—during

activation or alarm—and include the proper values for loading

calculations. Connected devices must not exceed system

capabilities during any possible operational mode.

2.5 Keypad Assignment

There are eight available slots for keypads. LED keypads by

default are always assigned to slot 1. LCD5500Z keypads are

always assigned to slot 8. You will need to assign each keypad

to its own slot (1 to 8). Keypad assignment is required, as it tells

the panel which slots are occupied. The panel can then generate

a fault when a keypad supervisory is not present.

One LCD keypad must be assigned to slot 8 in

order to upload keypad programming using

DLS-1 software.

How to Assign Keypads

Do the following at each keypad installed on the system:

1. Enter [✱][8][installer’s code] to go to installer programming

2. Enter [000] for Keypad Programming

3. Enter [0] for Slot Assignment

4. Enter a two digit number (11-18) to specify which supervisory

slot the keypad will occupy.

5. Press [#] twice to exit installer programming.

B

C

A

PANEL

500’

500’

150’

150’

B

C

A

PANEL

500’

500’

150’

150’

Loading...

Loading...