45

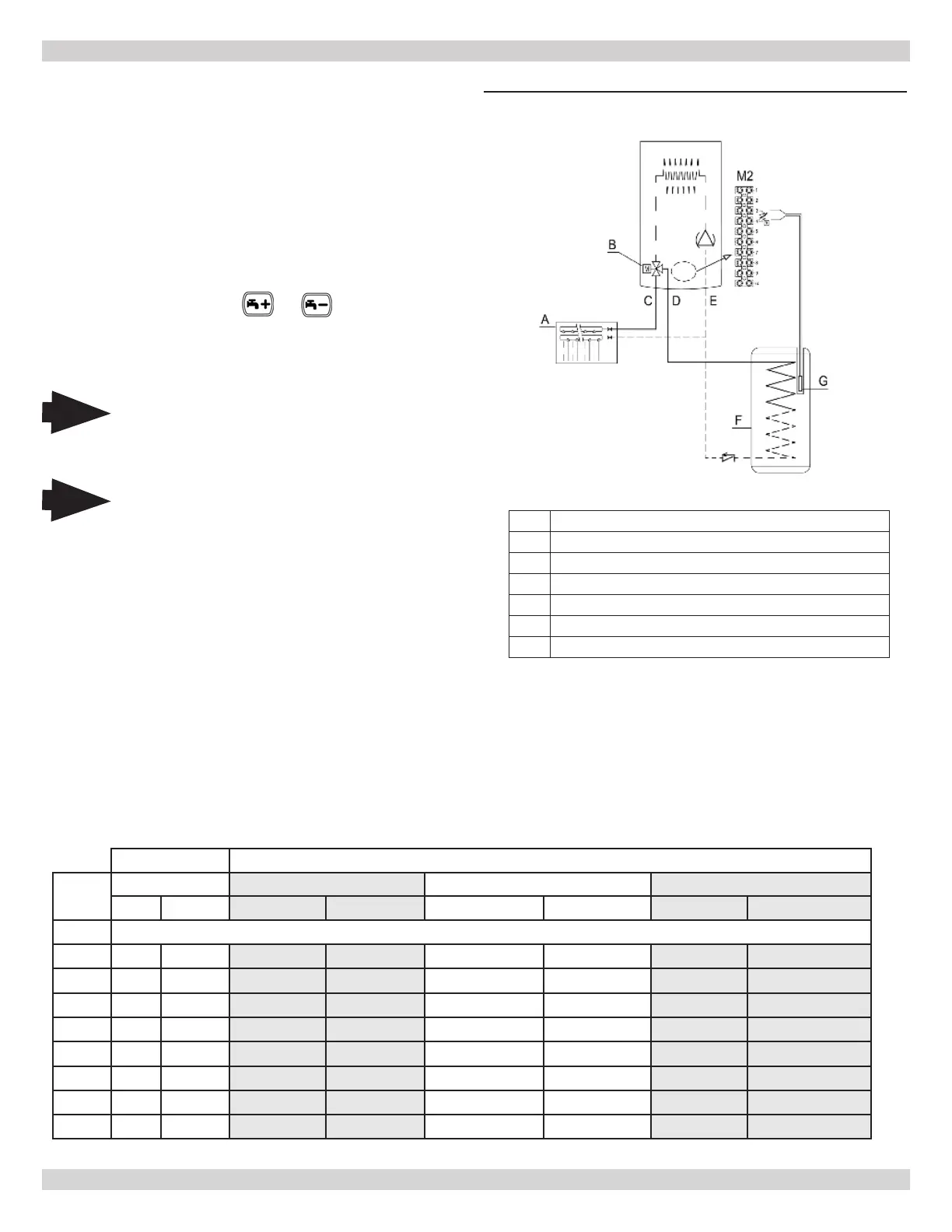

8.8 Indirect Storage Tank

A Heating system

B Three way diverter valve

C

D Heating supply to DHW indirect storage tank coil

E Heating water return

F Tank

G

Boilers DCB-100 & DCB-125 can be electrically connected to

indirect storage tank as follows:

• Connect DHW priority 10K Ω sensor NTC to terminals 3-4

on terminal block M2.

• Insert 10K Ω NTC sensor element in the sensor well of

indirect storage tank.

• Verify exchange capacity of the storage boiler coil is

appropriate for boiler power.

• Adjust DHW temperature +95 °F...+140 °F (+35

°C...+60 °C) by pressing

or on boiler Control.

IMPORTANT: set parameter P03 = 05 as described in:

"PARAMETER SETTINGS".

8 - ELECTRICAL CONNECTIONS

FIGURE 8-7 Kt Indirect Storage Tank

*125 Model shown - See Application Guide for size 100

Note

Sensors used for this boiler are proprietary to

the manufacturer. Use of after market sensors

will diminish boiler performance.

10K Ω Sensor

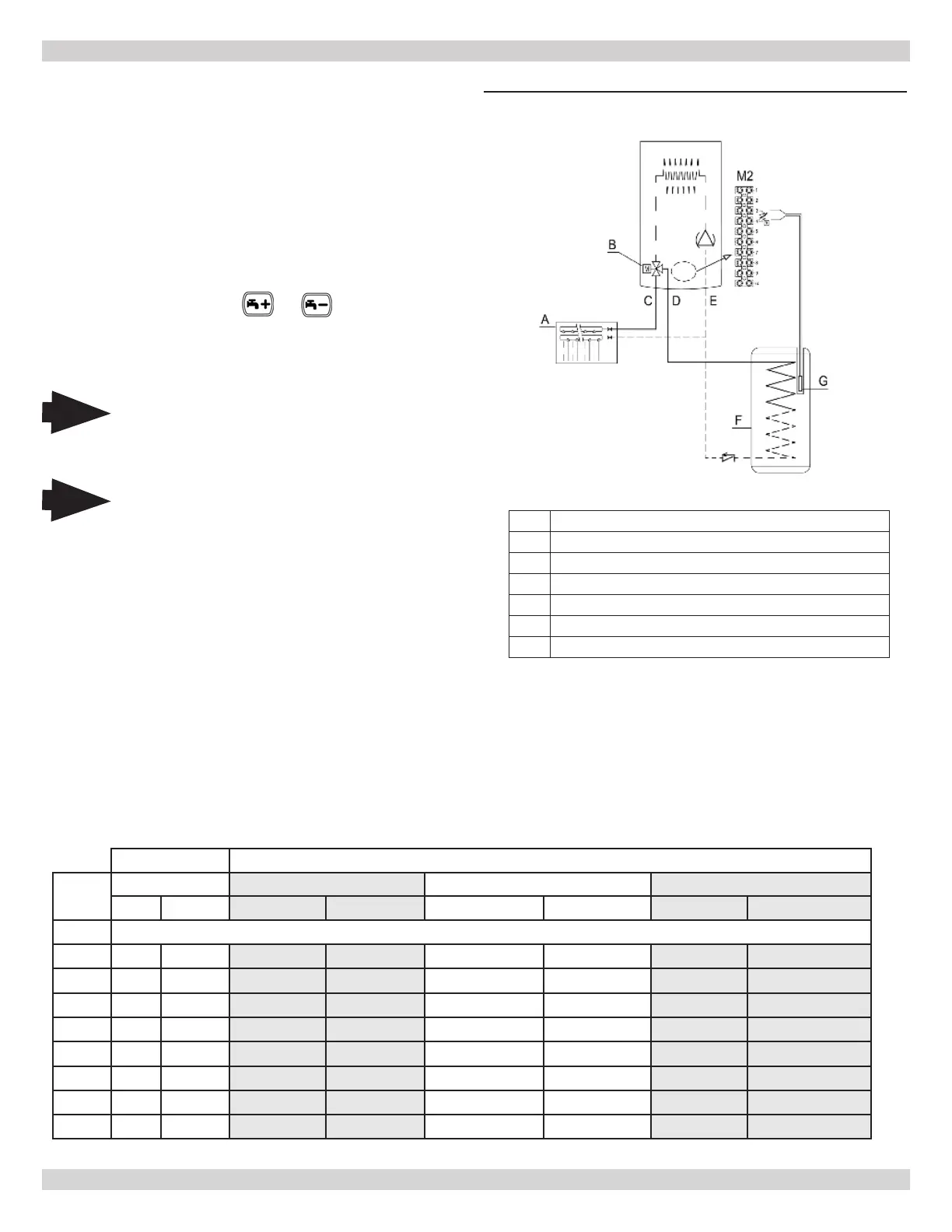

8.9 Management of 0-10V Input

The functions with 0...10V regulator are activated by means of their parameters:

To enable 0-10V input change P82=4 to P82=3,

When P78=1 the input manages the heating set point temperature directly.

When P78=2 the input manages the heating power input directly.

Demand is activated above 3V and heating setpoint is calculated in proportion to deviation from 3 to 10 V DC, to give a

setpoint that goes from minimum to maximum.

Terminal # 9 is negative (-), terminal #10 is positive (+).

P78=1 P78 = 2

Voltage Temp Setting 100/115 125/150 165/205

°C °F kW MBH kW MBH kW MBH

0-3 OFF

3 25 77 4.9 16.6 6.4 22.0 8.6 29.5

4 32 90 8.4 28.9 10.7 36.5 14.4 49.0

5 40 104 12.0 40.8 14.9 51.0 19.9 68.0

6 49 120 15.4 52.4 19.2 65.5 25.5 87.0

7 57 135 18.5 63.1 23.4 80.0 31.1 106.0

8 65 149 22.2 75.7 27.7 94.5 36.6 125.0

9 73 163 25.3 86.2 31.9 109.0 42.5 145.0

10 80 176 27.4 93.6 36.9 125.0 48.1 164.0

Note

Model 165 Use aquastat for Indirect Tank

Control.

240013360

REV A [07/01/2021]

Loading...

Loading...