1-26

12H-M12M0-0309-0

2-5. Paper Ejection Mechanism

To enhance paper ejection stack performance and processing speed, the paper ejection drive mechanism is

intermittently driven by the electromagnetic clutch. To improve operability, the movement of the stacker roller has

been made automatic.

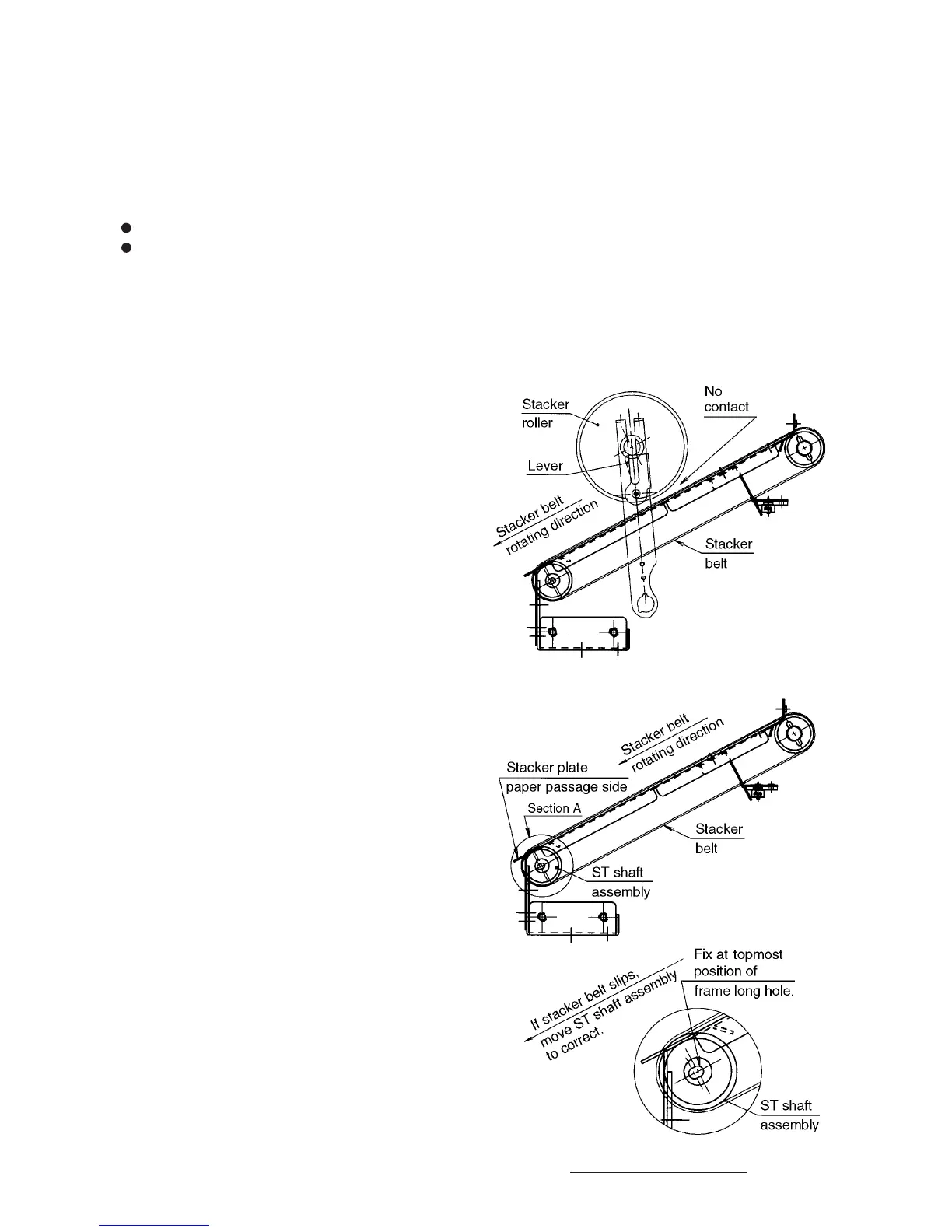

2-5-1. Replacing the stacker belt

Take note of the following points when replacing the belt.

Belt front/back : The green side is the front.

Rotating direction of the belt: The rotating direction is indicated by an arrow on the belt back (black side).

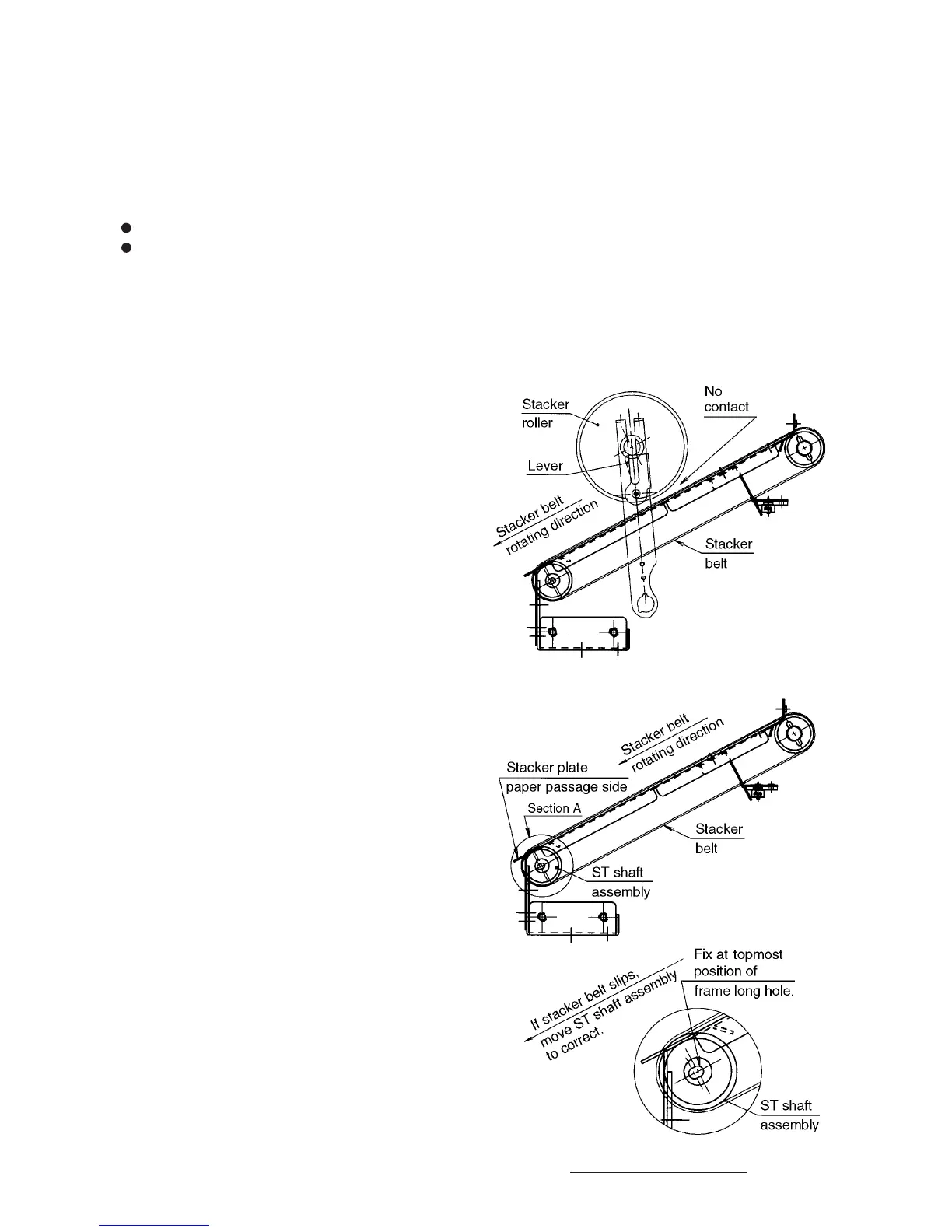

2-5-2. Adjusting the tension of the stacker belt

Perform the following check and adjustment if the stacker belt slips while rotating.

Normally, the belt slips due to the change in the frictional coefficient between the stacker plate and belt back from the

load of the stacker roller.

q If the belt slips with the stacker roller and belt not

contacting (the stacker roller is raised), perform step

w.

If the belt does not slip in this state, perform step e.

w Generally, the ST shaft assembly is fixed at the

topmost position of the frame long hole. This state is

the recommended stretch rate of the belt. (Stretch

rate: 4%)

If the belt slips, loosen the screw fixing the ST shaft

assembly, and adjust the tension of the belt by

moving the assembly.

The adjusting range is within 2 mm (0.08").

e The area where the stacker plate and belt back

contact each other is pasted with a Teflon tape to

reduce the frictional coefficient. The belt may start to

slip when the effects of the tape drop. In such cases,

paste a new tape.

(NITTO DENKO NITOFLON tape No.973UL t0.13 ×

W15)

Enlargement of section A

Loading...

Loading...