1-10

12H-M12M0-0309-0

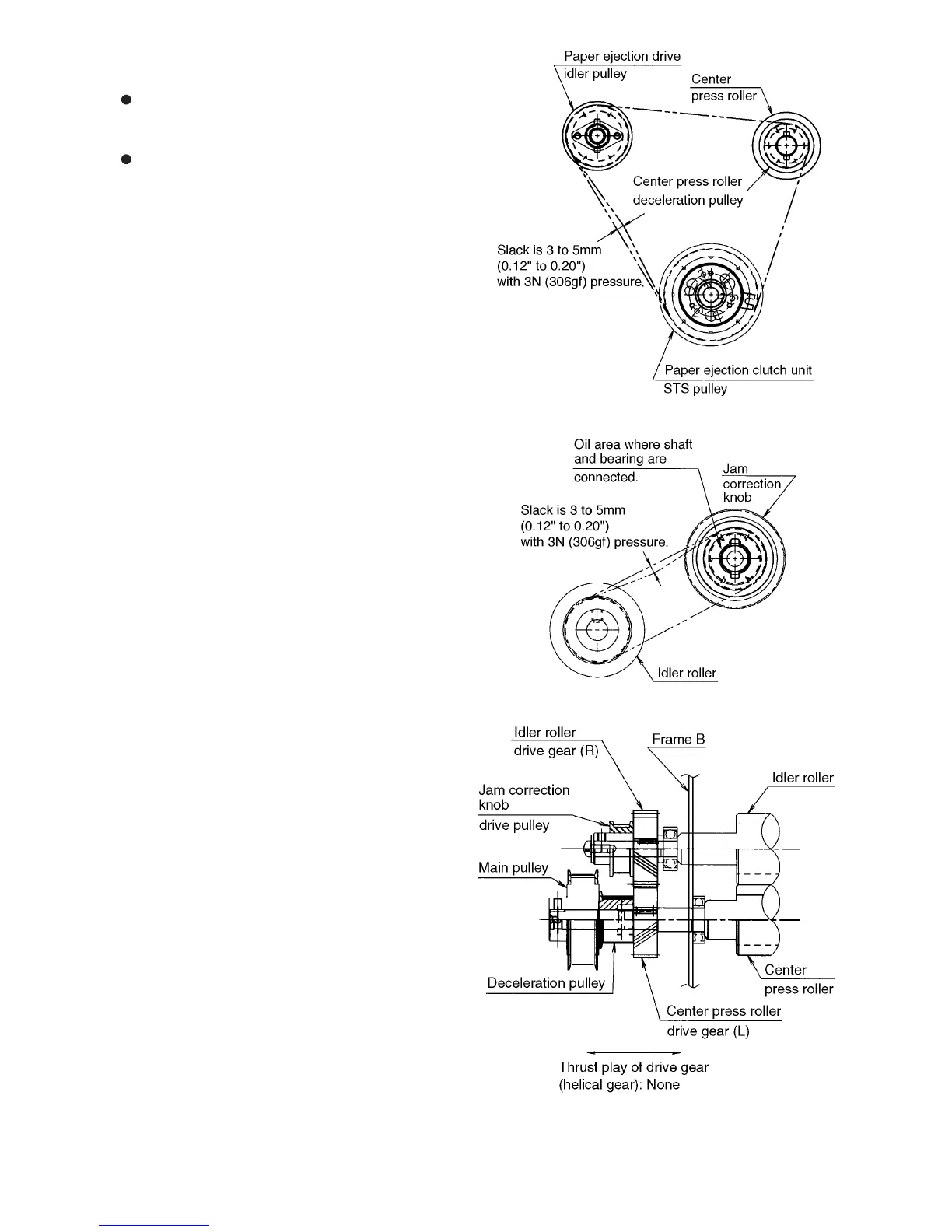

(8) Adjusting the tension of the paper ejection

drive timing belt

Inappropriate tension of the belt may cause such

problems as noise, slips, etc.

Using a tension gauge of 5 N (510 gf), apply

pressure of 3 N (306 gf) to the belt, and check

that the belt slacks by 3 to 5 mm (0.12" to 0.20").

(9) Adjusting the tension of the drive belt for the

jam correction knob

The jam correction knob rotates the folding rollers

during jam correction and cleaning of folding rollers

to facilitate work.

q Check that when the jam correction knob is

rotated, the folding rollers rotate smoothly.

w Using a tension gauge of 5 N (510 gf), apply

pressure of 3 N (306 gf) to the belt, and check

that the belt slacks by 3 to 5 mm (0.12" to 0.20").

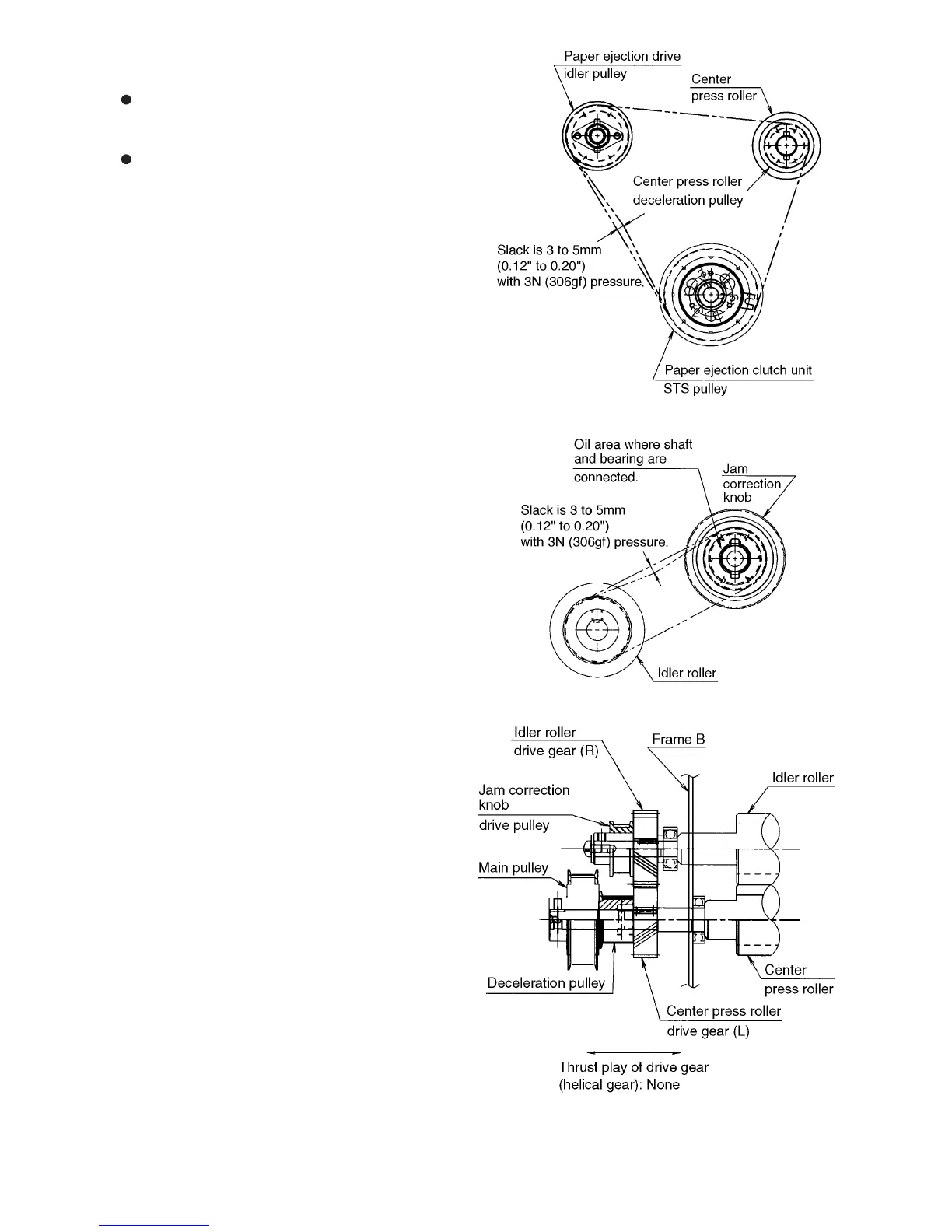

(10) Attaching the main pulley of the center press

roller, and jam correction knob drive pulley of

the idler roller

q While pressing the main pulley against the frame

B side so that there is no thrust play of the helical

gear, attach it to the center press roller.

w While pressing the knob drive pulley against the

frame B side so that there is no thrust play of the

helical gear, attach it to the idler roller.

Loading...

Loading...