1-6

12H-M12M0-0309-0

2. OUTLINE OF MECHANISMS AND ADJUSTMENTS

2-1. Folding Section and Drive Mechanism

The folding section is the most basic paper folding mechanism. It is composed of folding rollers, press lever, reference

stoppers, etc.

The drive mechanism distributes driving force from the main motor to the folding rollers, paper feed mechanism, and

stacker mechanism.

2-1-1. Cleaning the folding rollers

Clean off dirt on the surface of the idler roller, center press roller, and folding rollers 1 and 2 with alcohol. Use of other

solvents may deform the surface of the rubber roller.

2-1-2. Replacing folding rollers

(1) Removing/attaching order of folding rollers

Remove in the order of idler roller, center press roller, folding roller 1, and folding roller 2.

Attach in the reverse order of the above.

As the center press roller is incorporated with a switching shaft unit, be careful not to deform the

switching angle during removal.

As the folding rollers are incorporated with keys, collars, and flat pins for securing the drive gears (helical

gears), be careful not to lose these during removal.

Make sure that there is no grease or oil on the side of the switching shaft passed by paper.

NoteNote

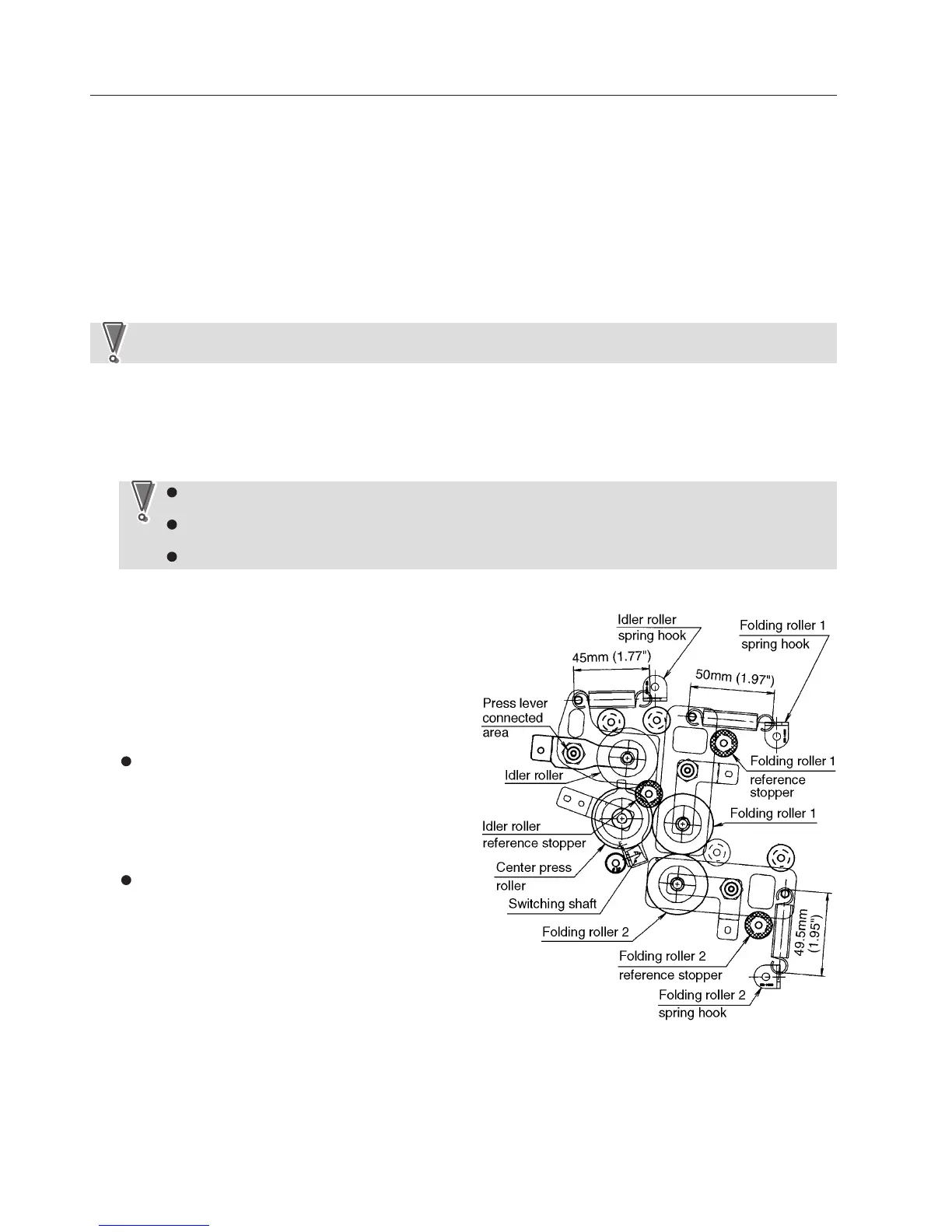

(2) Attaching the press lever

Apply a small amount of oil to the area where the

press reference pillar and press lever are

connected.

(Orelube G90-140: Equivalent to ISO #460)

(3) Attaching the reference stoppers

The reference stoppers minimize deformation of

the rubber roller (nip), maintain appropriate

distance between the folding roller shafts, and

maintain backlash of the drive gear (helical

gear).

Secure the reference stoppers in the order of

idler roller, folding roller 1, and folding roller 2

with the folding rollers in contact.

Always turn off the power when cleaning. Also take precautions against fire and ensure ventilation when using

alcohol.

NoteNote

Loading...

Loading...