1-14

12H-M12M0-0309-0

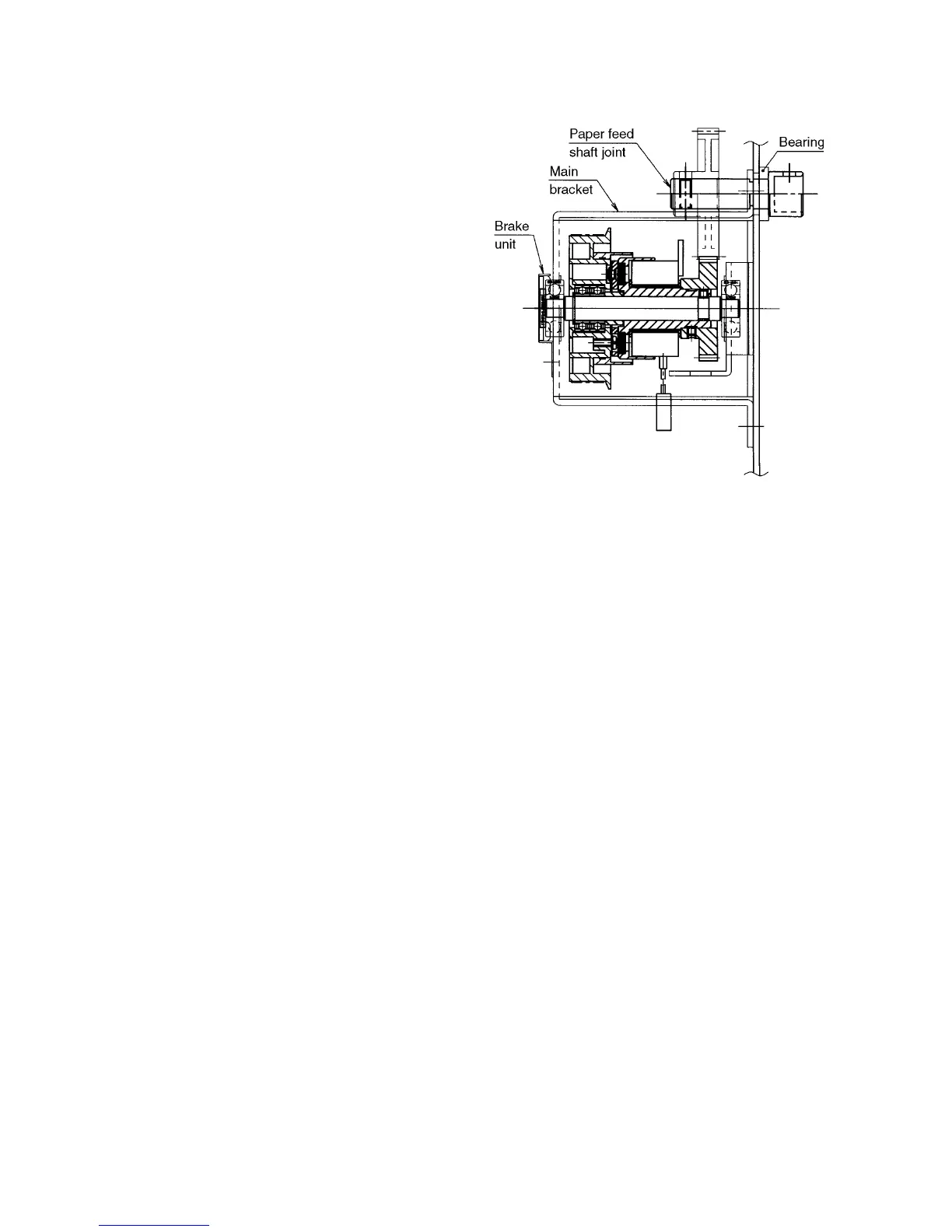

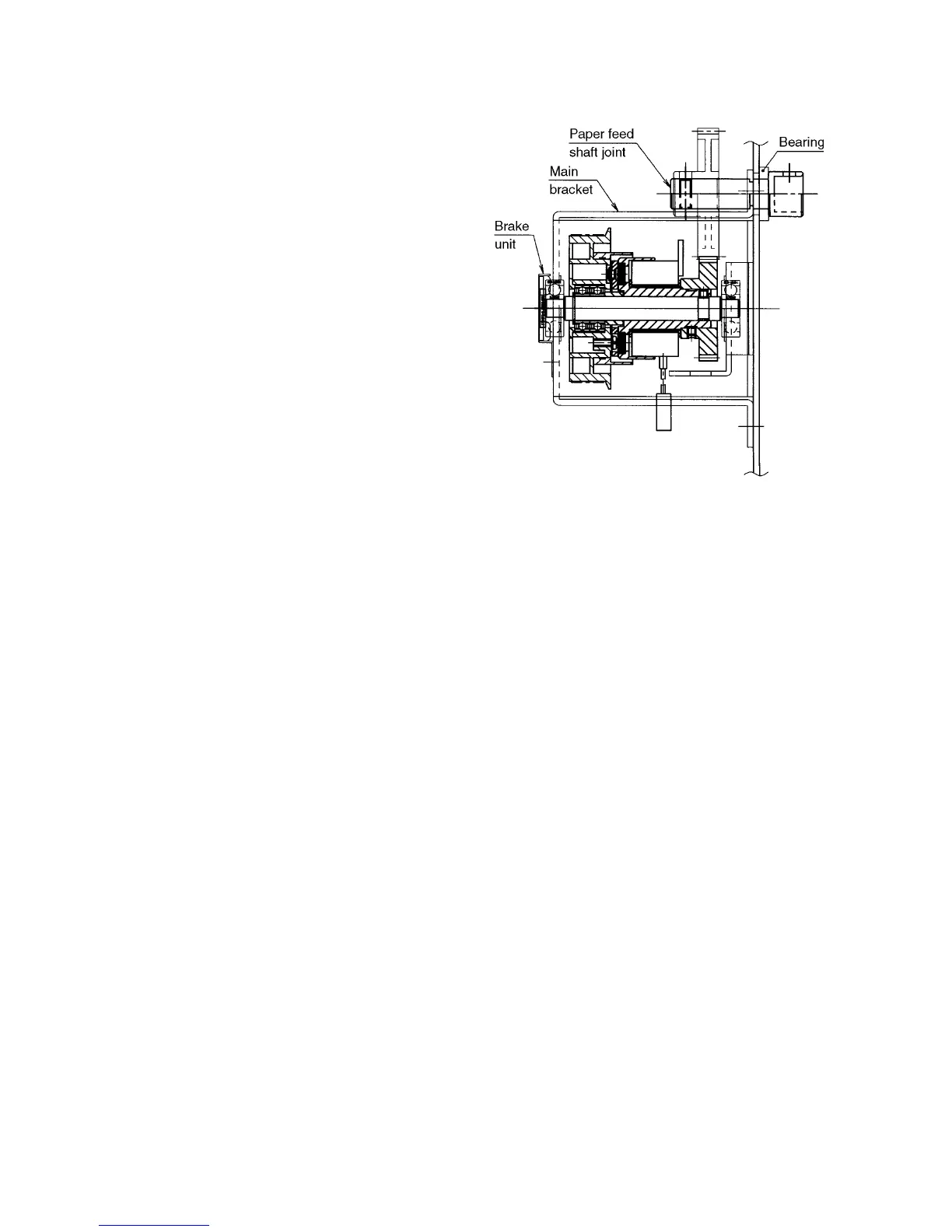

2-1-7. Attaching the brake unit

The brake unit reduces inconsistency in the stopping position of the paper lead edge during paper feed, and stabilizes

the jam detection timing and number of sheets processed.

q To prevent abnormal sounds due to the use of the

friction brake mechanism, apply a very small amount

of grease to the urethane area of the brake unit and

attach. (Orelube G1650)

w After attaching the brake unit, check that the rotating

torque of the paper feed shaft unit is 0.0147 to 0.0245

Nm (0.15 to 0.25 kgf • cm) with the paper separator

and paper feed ring not in contact.

However, even if the rotating torque does not meet

the above value, if the stopping position of the paper

lead edge is stable without touching the paper feed

inlet sensor it means that paper feed is stable and no

re-adjustments are required.

e Apply a very small amount of oil to the area where the

paper feed shaft joint and bearing are connected.

(Orelube G90-140)

Loading...

Loading...