1-18

12H-M12M0-0309-0

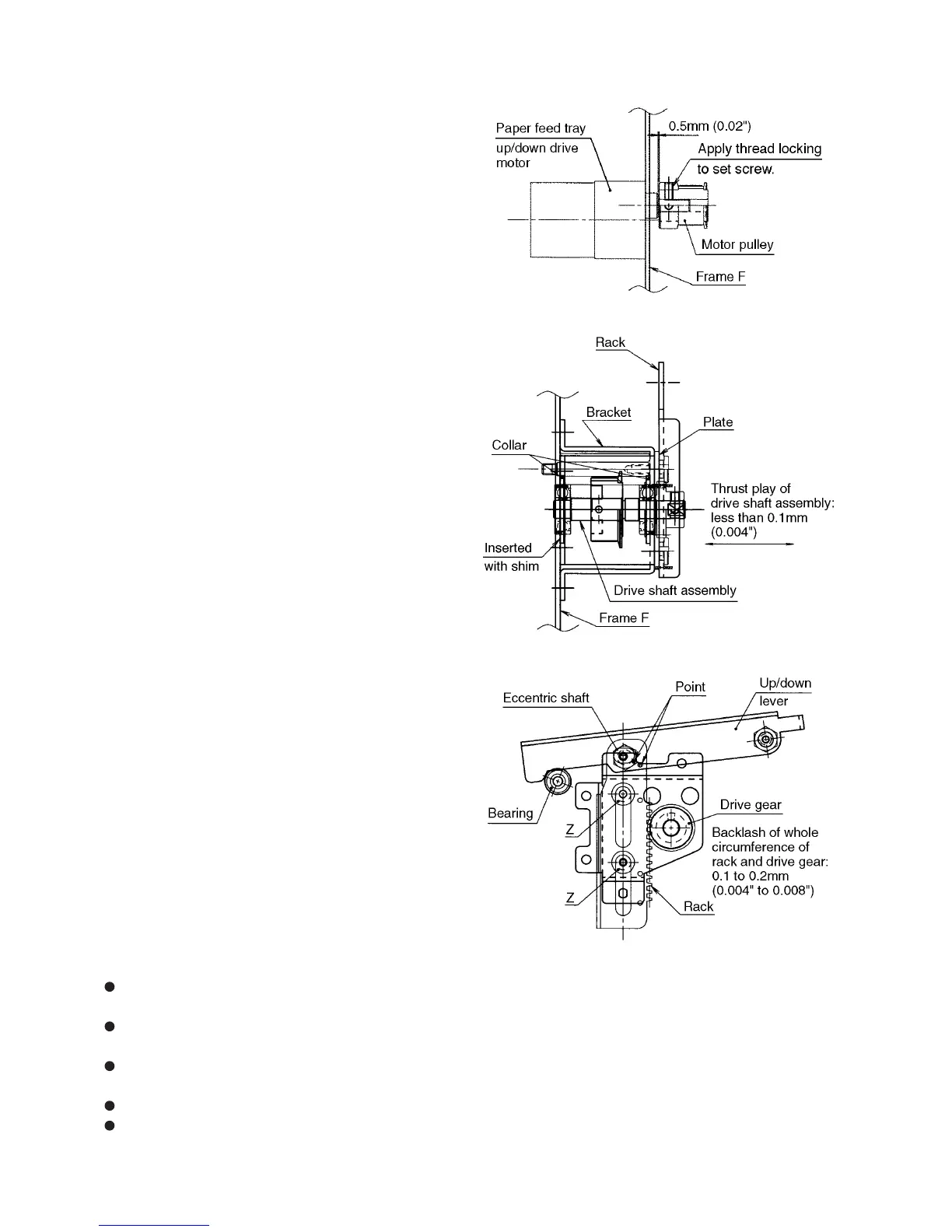

2-2-5. Automatic up/down mechanism of paper feed tray (DF-920 only)

If this mechanism has been removed during motor replacement, attach it using the following procedure.

q Attach a pulley to the drive motor at the position

shown in the figure.

w Apply a very small amount of thread locking to the set

screw. (Loctite 242: Medium strength/for screws)

e Check for thrust play of the drive shaft assembly. At

shipment, a shim (adjusting washer) is inserted

between the collar and bearing (outer ring) at frame F

side to control thrust play to below 0.1 mm (0.004").

Check that thrust play is not minus (pressed state).

r While ensuring the e state, insert the bearing and

collar at the bracket side, and secure the bracket.

t Apply a very small amount of oil to the area where the

drive shaft and bearing are connected.

(Orelube G90-140)

y Attach the plate and rack so that their surfaces touch

and slide.

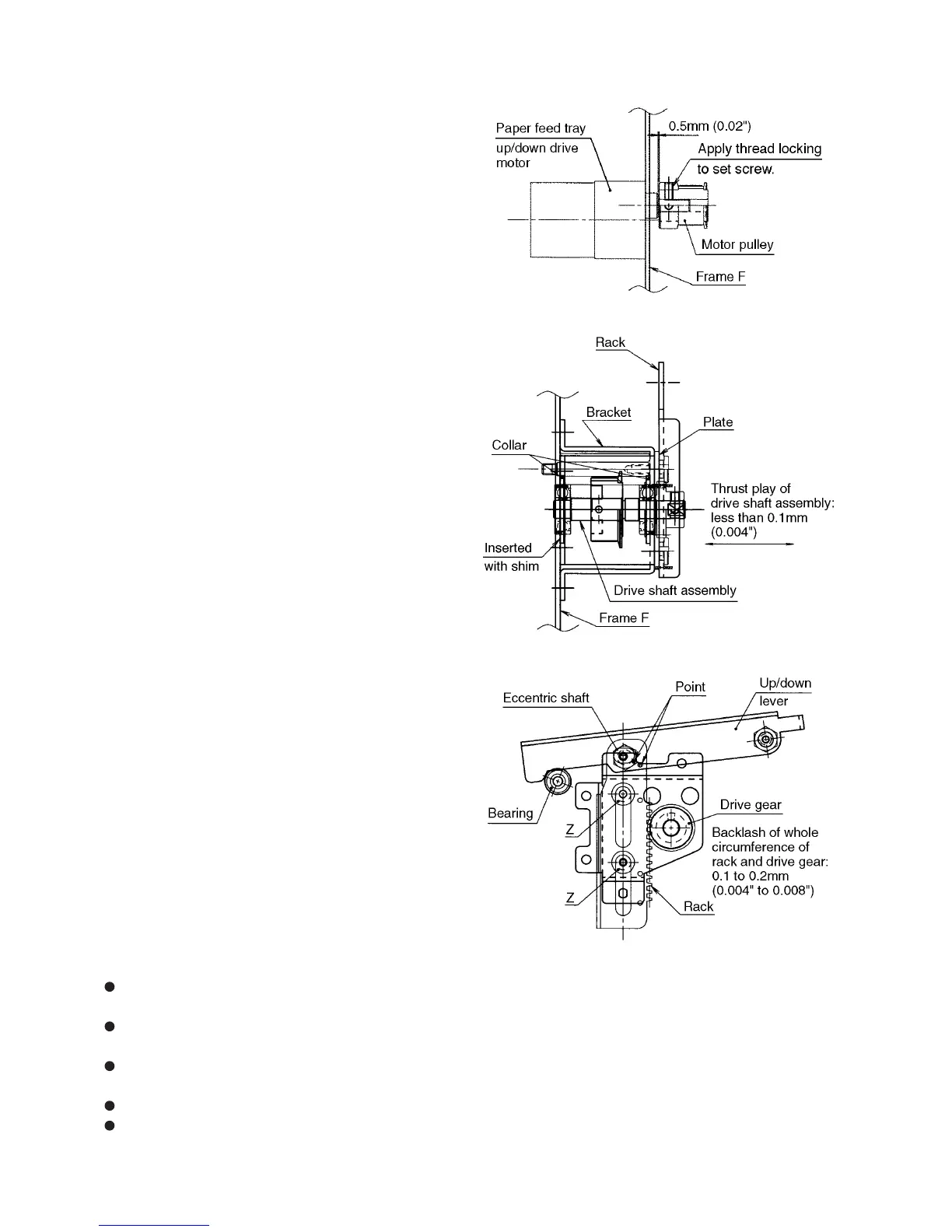

u Adjust the points on the eccentric shaft and rack, and

secure temporarily. (Primary adjustment)

i Move the rack up and down, and check that there is

appropriate backlash (0.1 to 0.2 mm (0.004" to

0.008")) where the rack and gear engage, and the

rack moves smoothly. Do not tighten the set screw of

the gear just yet. Tighten after completing the

adjustment of “2-2-7”.

The rack fulcrum Z (0Z4-08022) is designated as a

semi-durable part. Replace it appropriately after

50000 times of up/down movements of the paper

feed tray.

o Apply grease to the following parts. (Orelube G1650)

Contacting area between the up/down lever and

bearing outer ring

Connected area and sliding area of the eccentric

shaft and rack long hole

Connected area and sliding area of the Z part and

rack long hole

Sliding area of the plate and rack

Engaged area of the rack and gear

Loading...

Loading...