G2030-II-S

Apr ‘19

- 12

Maintenance Procedures (cont’d)

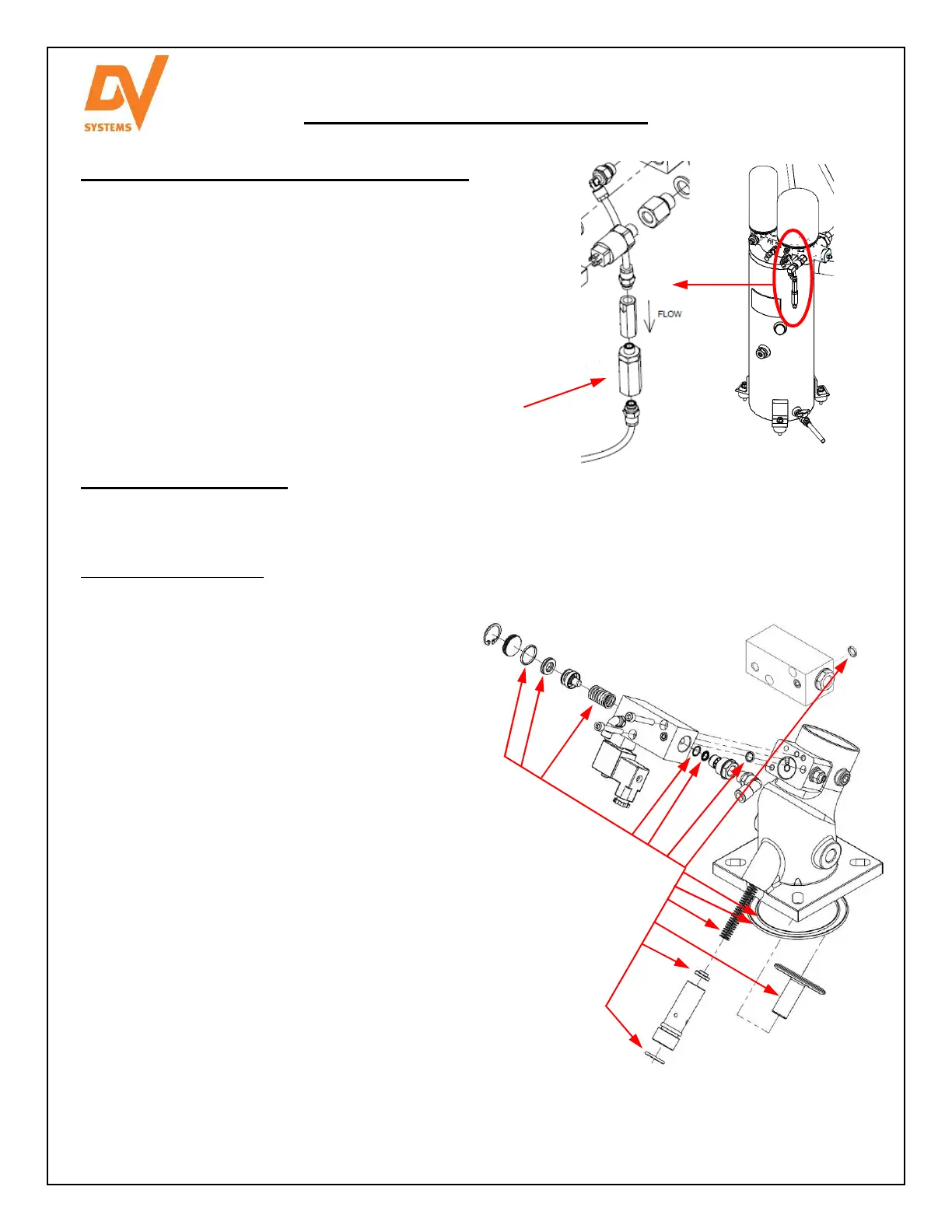

Intake Valve Repair Kit.

The Intake Valve Assembly is located directly below the Intake Filter, and opens and closes to allow air to enter

the Air End.

To repair the Intake Valve:

• Remove the Intake Filter from the top of the

Intake Valve Assembly.

• Remove the DIN Connector from the Solenoid

Valve attached to the Intake Valve Assembly.

• Remove the Intake Valve Assembly by way of

removing the (4) Screws attaching it to the Air

End

• Place a clean rag over the Air End to ensure

that nothing enters it.

• Remove the (2) Screws holding the aluminium

Manifold onto the Intake Valve.

• Remove the internal components from the

Manifold, clean the interior, and install new

components.

• Remove the Large Set Screw from the bottom

of the Intake Valve, and remove the Plunger.

• Clean the internal surfaces of the Intake Valve

and insert the new components.

• Secure the Set Screw.

• Install a new O Ring between the Manifold and

Intake Valve and secure with (2) Screws.

• Remove the rag from the Air End, install the O

Ring, and secure the Intake Valve.

• Reconnect the DIN Connector to the Solenoid,

and re-attach the Intake Filter.

Please order (1) ‘DSC-001999 Intake Valve Repair Kit.

Shown at right are the various components associated

with the Intake Valve Repair Kit.

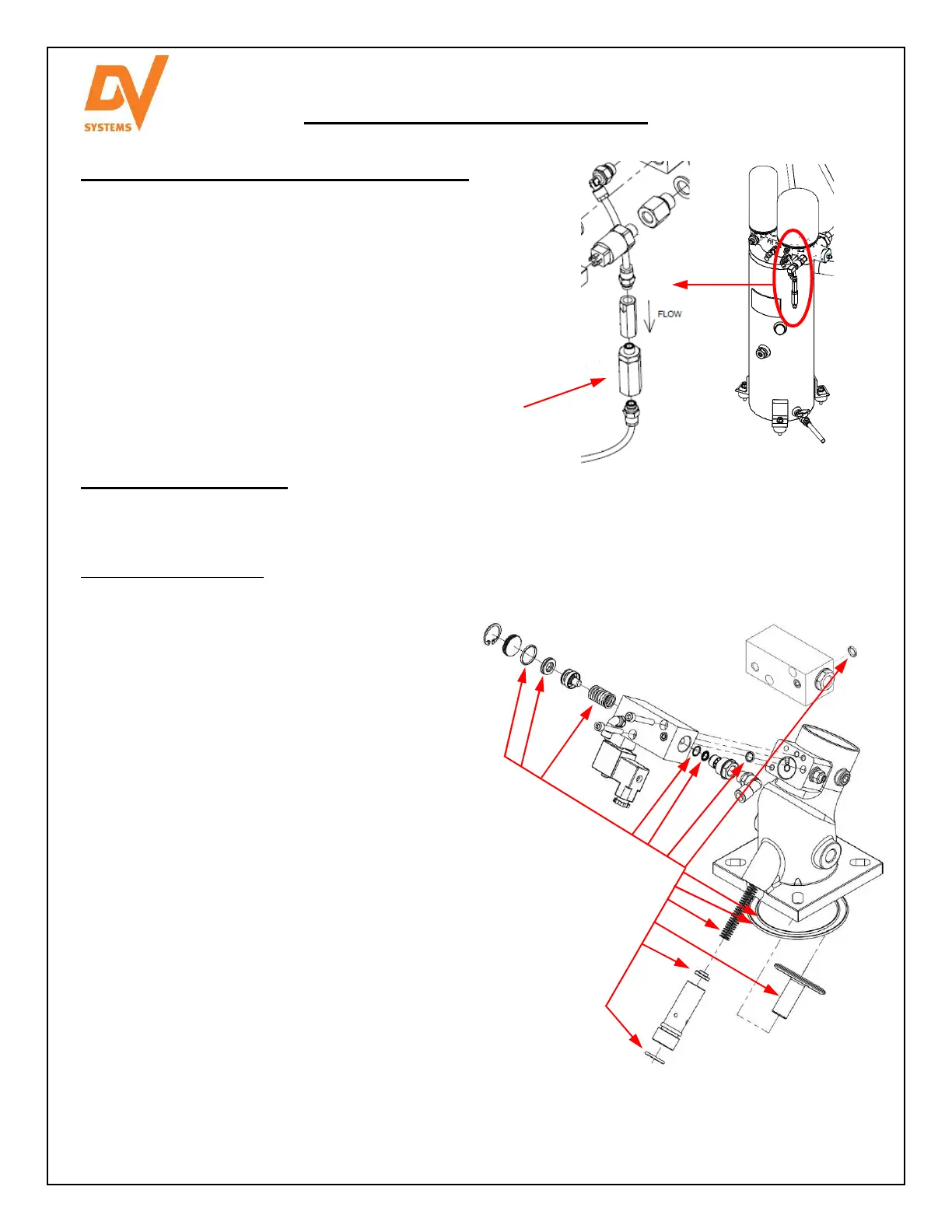

Changing the Scavenge Line ‘In-Line’ Filter.

The ‘DSC-612’ In-Line’ Filter is located in the Scavenge

Line between the Air-Oil Separator and the Air End, and

removes any particles from the oil before it enters the Air

End. The Filter must be replaced every 4000 hours to

ensure the proper flow of oil through the Scavenge Line.

When re-assembling the parts, use Loctite thread

sealant. Do not use Teflon tape, as the tape could come

loose and obstruct the passage of oil.

In-Line Filter

Loading...

Loading...