G2030-II-S

Apr ‘19

- 16

‘CSC300’ Controller (cont’d)

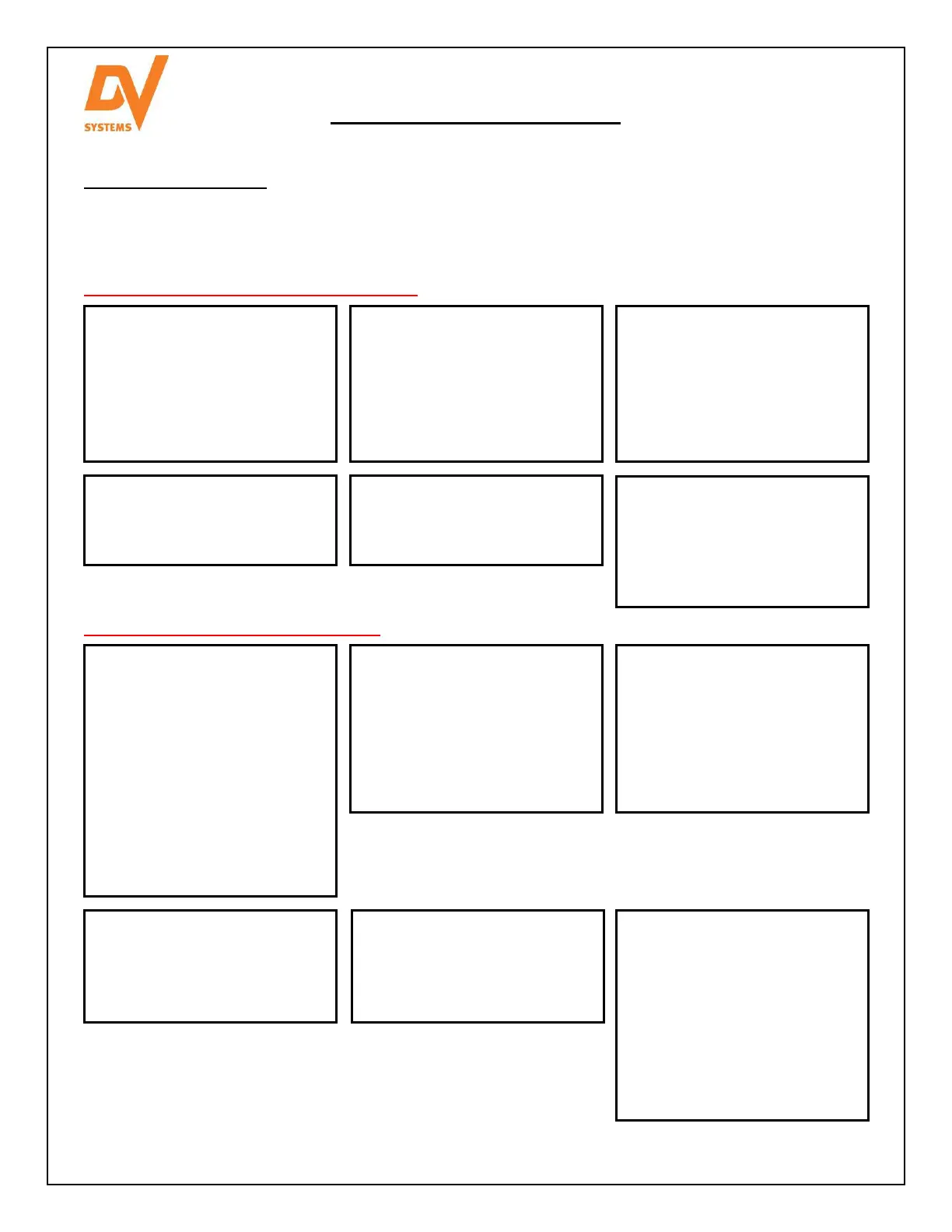

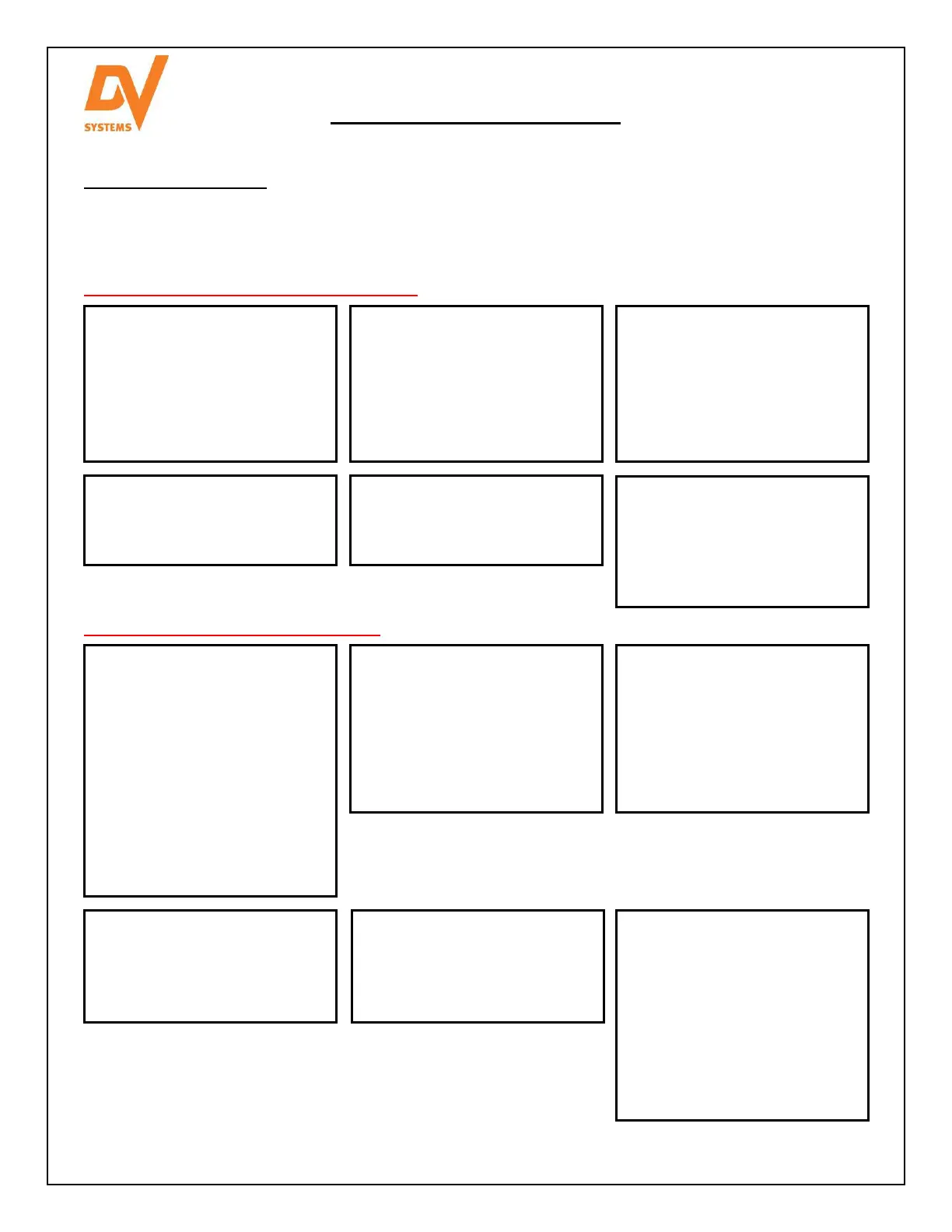

Controller Structure.

The chart below indicates the various fields of the ‘CSC300’ Controller, some require an Access Code. As

suggested on the previous page, only those qualified should be permitted to make any adjustments to the

parameters.

Default Level Available Without Access Code

Service 1 Level Requiring Access Code:

Page ‘P00’ - Home

01 Any active alarm

02 Control Mode

06 COMP OUT TEMP

07 EQUIP OUT PRESS

13 Time

14 Date

16 ISC Sequence

Page ‘P10’ – Equip settings 1

04 Load pressure

05 Off load pressure

06 Run period

07 Offload period

10 Start source

11 Load source

12 Language

13 Time

14 Time format

16 Date

17 Date format

18 LCD light level

19 Pressure unit

Page ‘P11’ – Equip settings 2

04 Reload INH time

05 Off load run time

06 Stop MIN time

07 Vent time

08 AUTO restart INH

12 MTR STR HR INH

14 Service hours 1

15 Service hours 2

Page ‘P13’ – VSD settings

02 VSD target PRESS

03 VSD MAX speed

04 VSD MIN speed

05 VSD OPT speed

06 VSD offload SPD

07 VSD speed RPM

08 VSD output CURR

Page ‘P01’ – Service Timers

01 Total hours

02 Load / off load HRS

03 Load hours

04 Off load hours

05 Stopped hours

06 Routine service hours

07 Grease service hours

Page ‘P02’ – Utilisation

02 Load/ offload hours

03 MTR STR last HR

04 MTR STR last 24H

05 Load frequency

06 Load % last hour

07 Load % last 24H

08 Load time last hour

Page ‘P03’ – Error Log

01 Error 1

to

50 Error 50

Page ‘P04’ – Event Log

01 Event 1

to

200 Event 200

Page ‘P09’ – Access

01 DEFAULT USER

02 ADMIN USER

03 Operator

04 Service 1

05 Service 2

06 Factory

Page ‘P16’ – Warning alarm

01 Service hours 1

02 Service hours 2

13 EQUIP OUT PRESS

36 EQUIP OUT TEMP

Page ‘P18’ – I/O CONFIG

08 DI5 function

09 DI5 OK: NO/NC

14 DI8 function

15 DI8 OK: NO/NC

19 Relay 8 function

Page ‘P20’ – Diagnostics

01 Digital input 1

to

08 Digital input 8

09 Analogue input 1

11 AI-3 - ohms

12 AI 3 – amps

13 AI 3- volts

18 Relay output 1

to

25 Relay output 8

26 Analogue output 1

Loading...

Loading...