G2030-II-S

Apr ‘19

- 5 -

AC Motor Maintenance Instructions

Cleaning.

To ensure that the Motor operates at optimum temperatures and provides years of trouble-free service,

periodically clean the outside of the Motor Housing of any build-up of dust, etc. Though it is not anticipated that, if

installed correctly and in a suitable environment, there should be much build-up on the Motor, keeping the

Housing clean will allow the Motor to operate more efficiently.

Lubrication.

This is a ball bearing motor. The bearings have been lubricated at the factory. Motors that do not have re-grease

capability are factory lubricated for the normal life of the bearings.

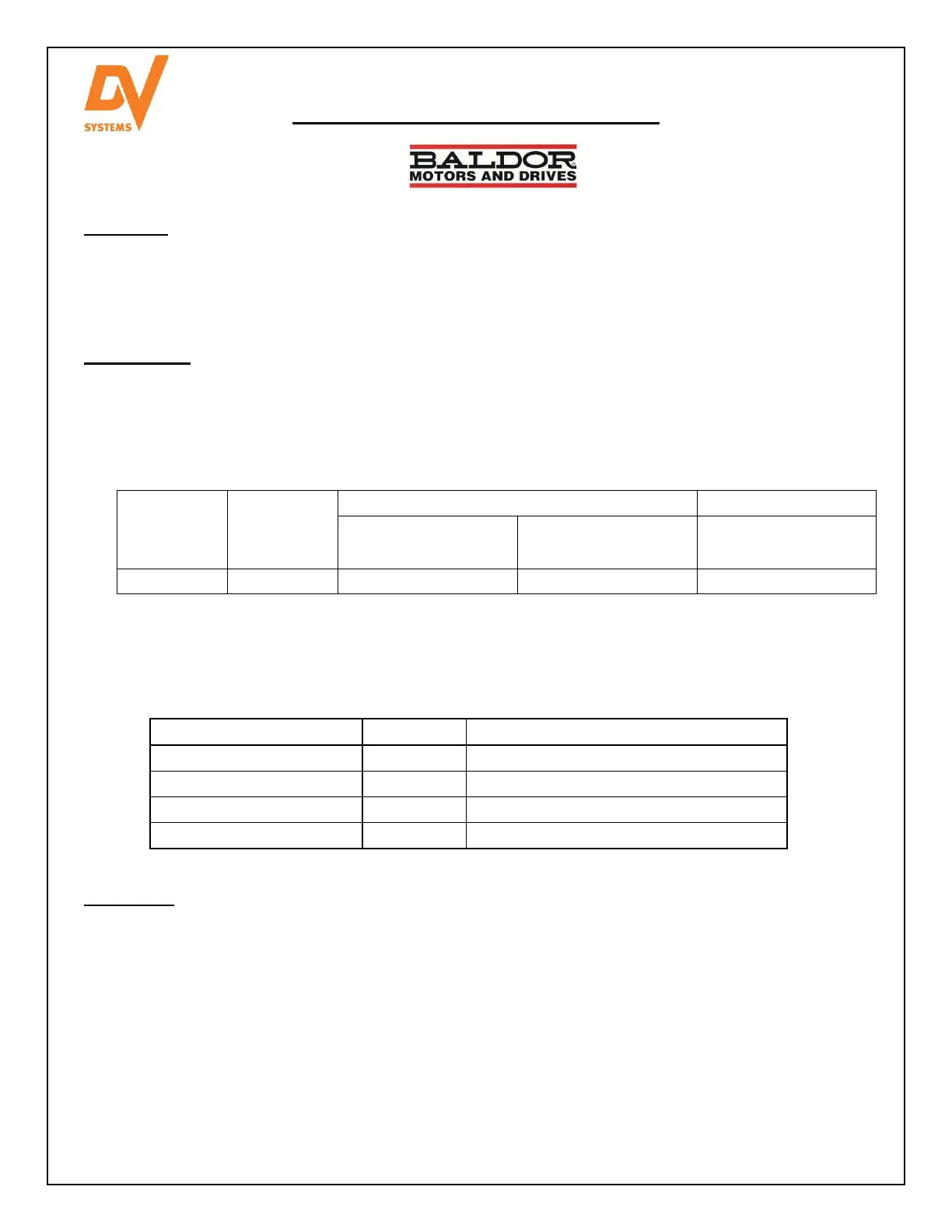

Some motor designs use different bearings on each motor end. Noted below is a chart outlining the interval at

which the bearings of Motor should be lubricated, this based on the Bearing Sizes. This must be part of a regular

maintenance schedule.

Motor HP

Interval

in Hours

Drive End *

Opposite Drive End **

Weight of Grease Volume of Grease Weight of Grease

Ounces (Grams) In

3

(Teaspoon) Ounces (Grams)

20 / 25 /30 2,000 0.61 (17) 1.2 (3.9) 0.23 (7.2)

*

Drive End would be the end that is connected to the driven device (air end).

**Opposite Drive End would be the end that is connected to the fan assembly.

The above chart is based on a standard environment in which the Motor is operating at 40°C (104°F). For other

conditions, please multiply the Hour Interval from the chart above by the factor as indicated below.

Severity of Duty Factor Environmental Conditions

Standard 1.0 40°C (104°F) , clean, little corrosion

Severe 0.5 50°C (122°F), moderate dirt, corrosion

Extreme 0.1 > 50°C (122°F), severe dirt, abrasive dust

Low Temperature 1.0 < 30°C (86°F)

Lubricant.

Baldor motors are pre-greased, normally with Mobil Polyrex EM. Equivalent and compatible greases are Texaco

Polystar, Chevron SRI #2, and Shell Dolium BRB.

Loading...

Loading...