EC5000

- 48 - - 49 -

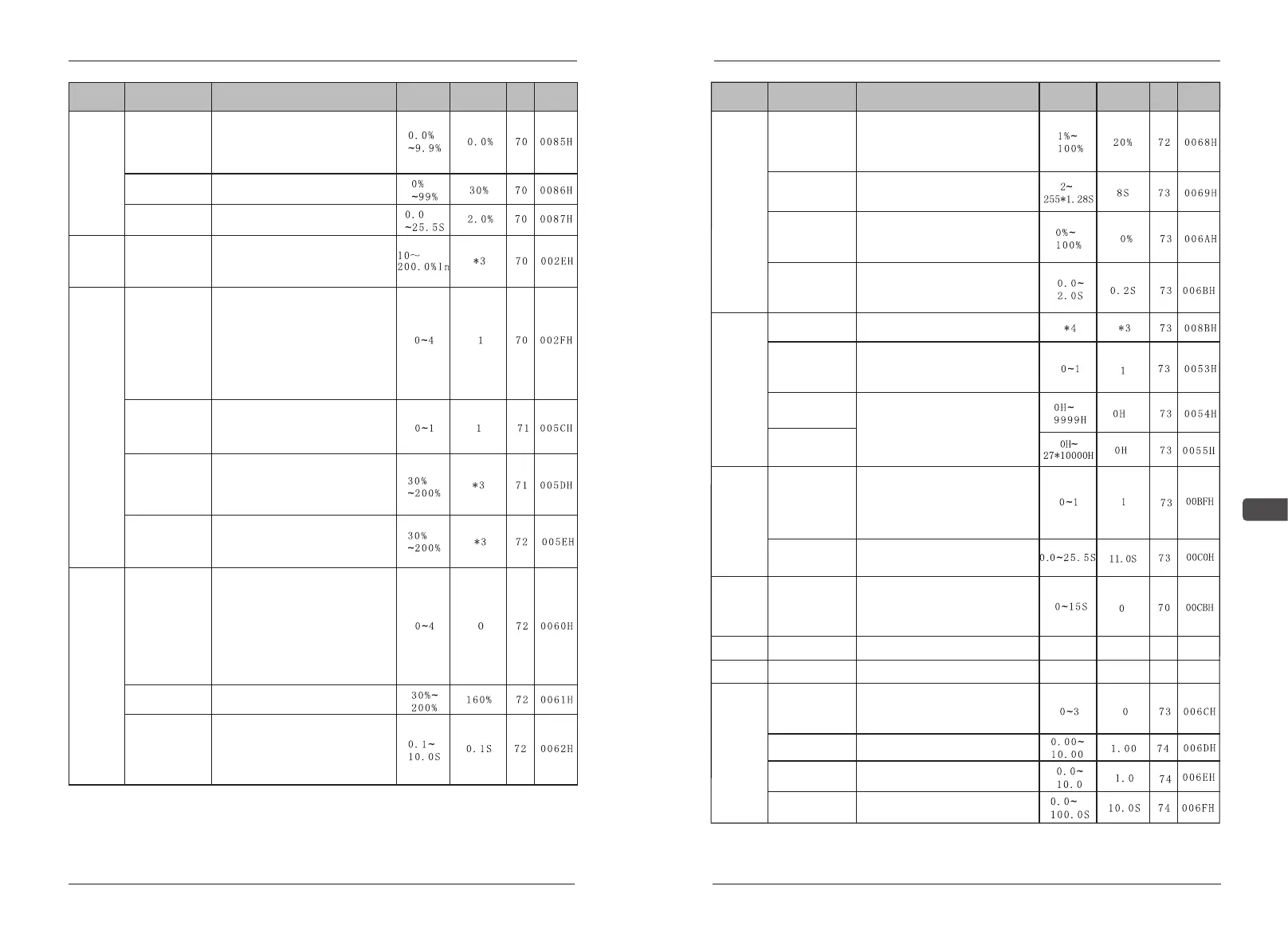

Description of Functional Parameter

5

EC5000

Description of Functional Parameter

Function

Parameters

Name

Description

Setting

range

Default

Page

Address

C15 Slip

compensation

gain

Rotation difference compensation is

increasing AC drive output

frequency by propotion of motor

loading capacity moment of force to

decrease motor speed difference.

Slip

correction

C16 Motor

no-load current

Motor no-load current

C17 Motor

no-load current

Slip compensation primary delay

time constant

Electronic

thermal

protector

C18 Motor rated

current

Set rated current value for motor

data plate, take the electronic

overheat protector as motor protec-

ting standard current.

C19 Motor

thermal

protection

0: Protection disabled

1: General purpose motor

(time constant 8 min.)

2: General purpose motor

(time constant 5 min.)

3: Blower-cooled motor

(time constant 8 min.)

4: Blower-cooled motor

(time constant 5 min.)

Over

current

stall

preven-

tion

C20 Stall

prevention

during

deceleration

0:without speed loss protection

function during retard

1:with speed loss protection function

during retard

C21 Current

limit/Stall

prevention level

during

acceleration

Unit:1%

AC drive rated curr

C22 Current

limit/Stall

prevention

Level during running

(Stall P Run Level)

Unit:1%

AC drive rated current 100

Output

over

torque

detection

C23 Over torque

detection

0: Detection disabled

1:Over torque detection at speed

agree; continue running after detec-

tion

2: Over torque detection at run;

continue running after detection

3:Over torque detection at speed

agree; coast to stop after detection.

4: Over torque detection at run;

coasts to stop after detection.

C24 Over torque

detection level

100%=inverter rated current

C25 Over-T

torque

If the time of motor current surpa-

ssing torque moment of force

testing standard(C24) is longer than

testing time(C25),over torque

moment of force testing function

works

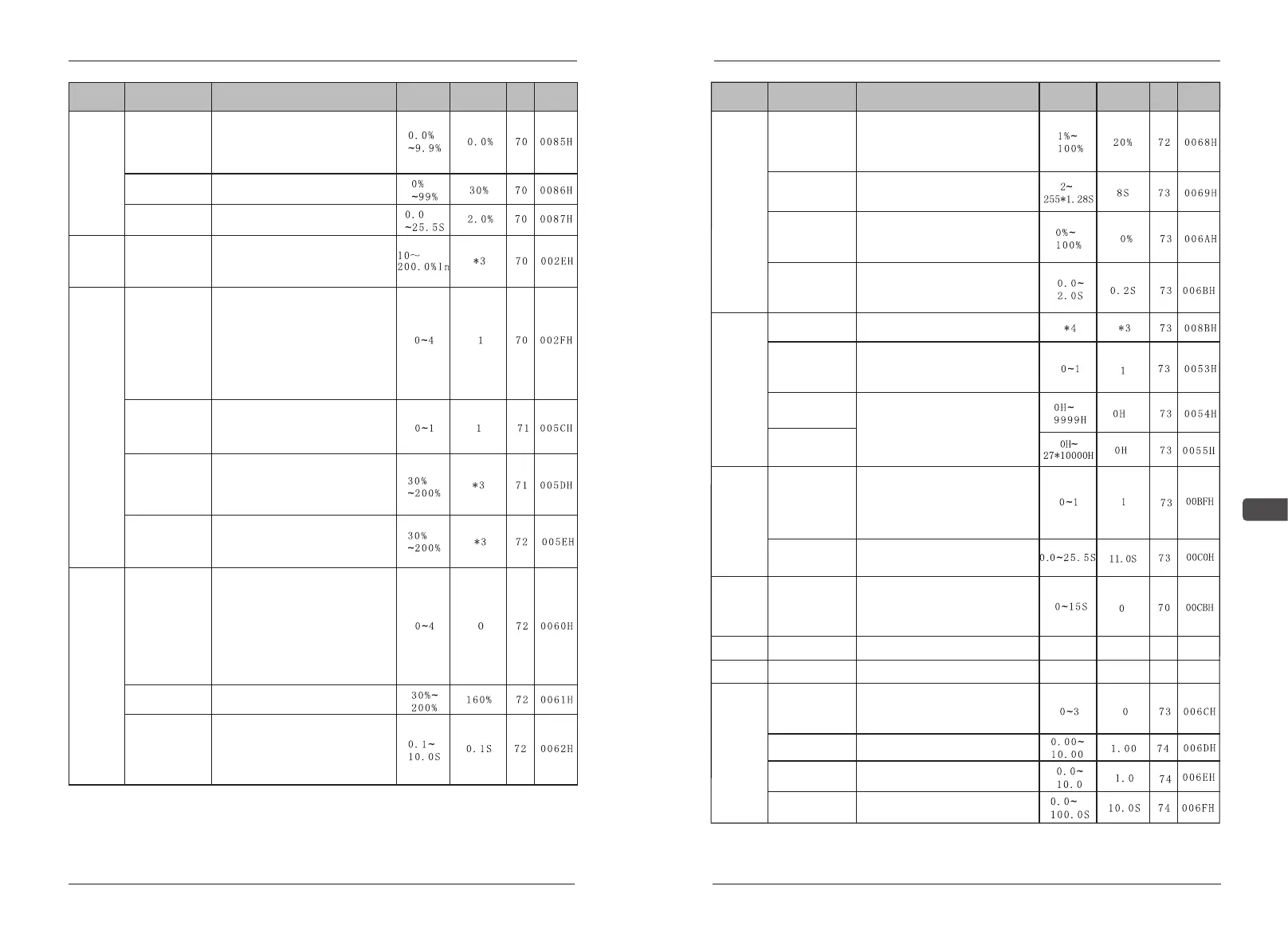

Function

Parameters

Name

Description

Setting

range

Default

Page

Address

Input/

Output

phase loss

detection

C26 Input phase

loss detection

level SPI

Unit:1%

When setting is 100%,this function

is disabled.DC400V (200V grade)

and DC800V (400Vgrade) to be

100%.

C27 Input phase

loss detection

delay time

C28 Output

phase loss

detection level

SPO

C32 Elapsed

timer L

C33 Elapsed

timer H

Set the input phase missing test

time

Test time=1.28sec×(C27’s value)

Unit:1%

AC drive rated current to be 100%.

C29 Output

phase loss

detection Delay

time

Set output phase missing test time.

AC Drive

elapsed

time

setting

C30 AC Driver

kVA

Read only, display the AC drive

power grade

C31 Elapsed

timer selection

0:total time of accumulative when

AC drive is power on

1:total time of accumulative when

AC drive is running

When C32 is selected to be action

total time, set C32 to be time with

unit of 1 hour and calculate time

from then on.

C34 Frequency

reduction

compensation

When the click in the weak mag-

netic control area, the torque force

is not enough, and frequency redu-

ction compensation needs to be

turned on to increase the torque.

0: OFF 1: ON

Frequency

reduction

compen-

sation

of weak

magnetic

control

area

C35 Frequency

reduction

time

Increase the compensation time of

torque frequency reduction.

C37

C38

Operation

control

C36 Operation

delay time

After the operation signal is given, a

delay function is added. When the

user uses AC drive to power on and

operate directly, the time delay of

0-15s can be set.

Reserved

Reserved

PID

Control

D01 PID Control

0: PID disabled

1: PID enabled

2: PID w/Feed forward

3: PID w/Inverted feedback

D02 Feedback

calibration gain

It’s the gain of PID feedback

detection value for fine adjustment

D03 PID

Proportional gain

Set P control proportion increase.

If set to be 0.0, no P control.

D04 PID

Integral time

Set I control proportion increase.

If set to be 0.00, no I control.

Loading...

Loading...