EC5000

- 50 - - 51 -

Description of Functional Parameter

5

EC5000

Description of Functional Parameter

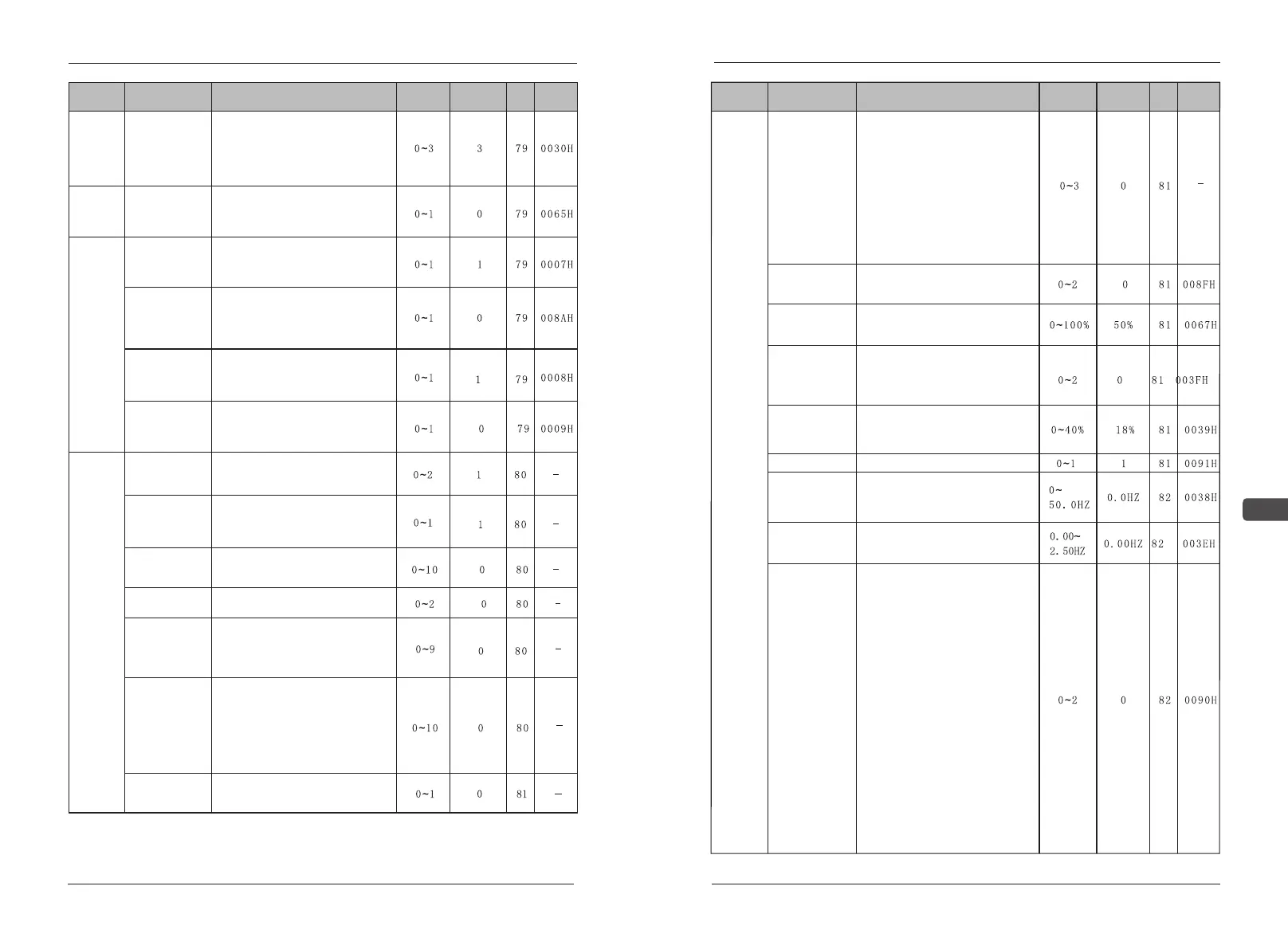

Function

Parameters

Name

Description

Setting

range

Default

Page

Address

F06 Stop

method

selection -OH1-

for inverter

overheat

pre-alarm

0:Ramp to stop-Decel 1(fault)

1:Coast to stop(fault)

2:Ramp to stop-Decel 2 (fault)

3:Continue operation(alarm) at 80%

of frequency reference.

Radiator

overheat

stop mode

F07 DBR

Overheat

0: without braking resistance

overheat protection

1:with braking resistance overheat

protection

Braking

resistance

overheat

protection

F08 Local/

Remote

key function

0:LOCAL/REMOTE key function:

invalid

1:LOCAL/REMOTE key function:

valid

Function

selection

of operator

F09 Local /

Remote

selection

0:When LOCAL/ REMOTE shifting,

re-run is valid when stop order is

inputed

1:When LOCAL/ REMOTE shifting,

re-run is valid at once

F10 Stop key

function

0:STOP key is disabled when

operated from terminals

1:STOP key is always enabled in

any operating mode

F11 Frequency

setting method

from Enter key

0:“ENTER” key not used when set

frequency order with operator

1:“ ENTER” key used when set

frequency order with operator

Auxiliary

function

F12 Monitor

Variable

unit selection

0: m/s

1:Mpa/mm²

2:Kg/ mm²

Pr F12 Pr Set

select

0:Frequency set by key button

number

1:Frequency set by key potentio-

meter adjustment

F13 Operation

panel LCD

brightness

Used to adjust the brightness of

LCD display.

Pr F13 Data

rewrite

0: Data copy 1: Data check

2: Data write

F14 Monitoring

parameter

selection

0: setting frequency

1: output frequence

2: output current 3: output voltage

4: output power 5: voltage EDC

6: feedback PID

Pr F14

Monitoring select

0: setting frequency

1: output frequency 2: output voltage

3: output current 4: output power

5: voltage EDC 6: feedback PID

7: temperature

8: S terminals functional

9: Y terminals functional

10: running time 11: version ROM

F15Operation

panel language

selection

0:Display Chinese

1:Display English

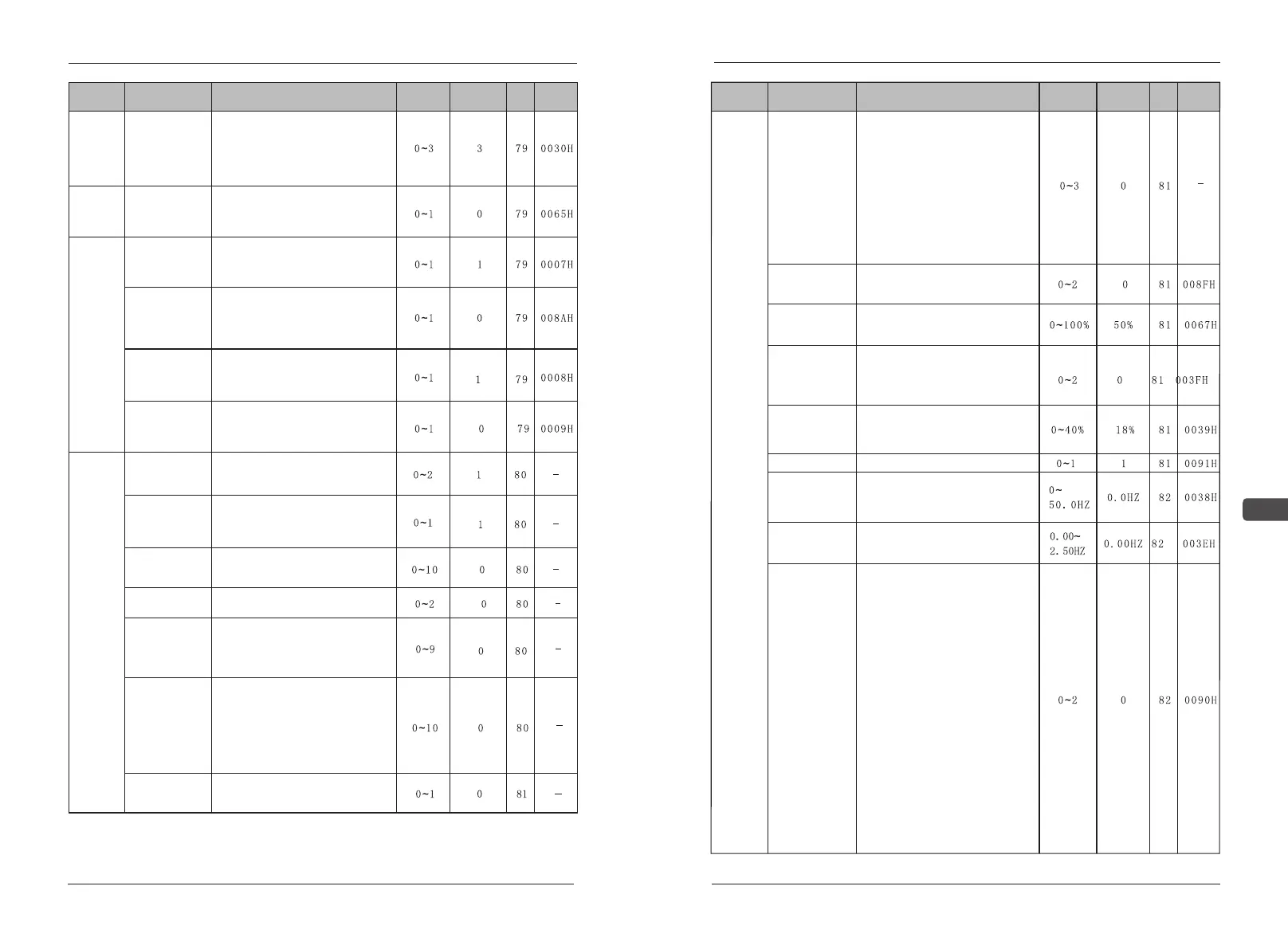

Function

Parameters

Name

Description

Setting

range

Default

Page

Address

Auxiliary

function

Pr F15 LED

Display selection

Only LED manipulator has this

functional code

0: seven items for monitoring:

(Fset、Fout、Vout、Aout、KVA、

EDC、PID)

1:increase two external terminals

S1-8 and Y1-4 for monitoring the

input and the output.

2:increase three items for monito-

ring: TEP、HOU、the VER of

mother board

3:increase five items which monito-

red above 1&2

F16 Low-speed

selection

0:Free running;

1:Running at A16(start freq) ;

2:Running at Zero-speed .

F17 Zero-speed

increase

According to the rating current of

100% set the output current at zero

speed.

F18 Motor tuning

0:no auto tuning;

1:static auto tuning(Suitable for use

in already connected load motor)

2:Dynamic auto tuning(Suitable not

connected to the load of the motor)

F19 Electrical

leakage

With motor set by 100% of the rated

voltage for motor voltage which is

caused by the leakage inductance

of the amount of pressure drop.

F20 AVR

0:No AVR 1:AVR

F21 Brake

frequency

0.00Hz The function is invalid

0.1~50Hz When the stop order is

given, DC injection braking when

deceleration to the set frequency.

F22 UP/DOWN

Step length

0.00Hz Choose the acceleration

time continuous accelerated to the

max frequency.

F23 Wire

selection

This function is enabled when use

terminal operation order.

The default is 0:

Single wire mode: connect S1 is

forward, disconnect S1 is stop.

Second wires mode: connect S1 is

forward, disconnect S1 is stop,

connect S2 is reversal, disconnect

S2 is stop. Three wires mode: S1

rising along the trigger, disconnect

S2 is stop, S3 level switch and

reversing.

The default is 1:

Single wire mode: S1 rising along

the trigger and stop switch Second

wires mode: connect S1 is forward,

disconnect S1 is stop. S2 level

switch and reversing Three wires

mode: S1 rising along the trigger is

forward, disconnect S2 is stop, S3

rising along the trigger is reversal

The default is 2:

Single wire mode: S1 rising along

the trigger and stop switch Second

wires mode: connect S1 is forward,

Loading...

Loading...