- 14 -

- 15 -

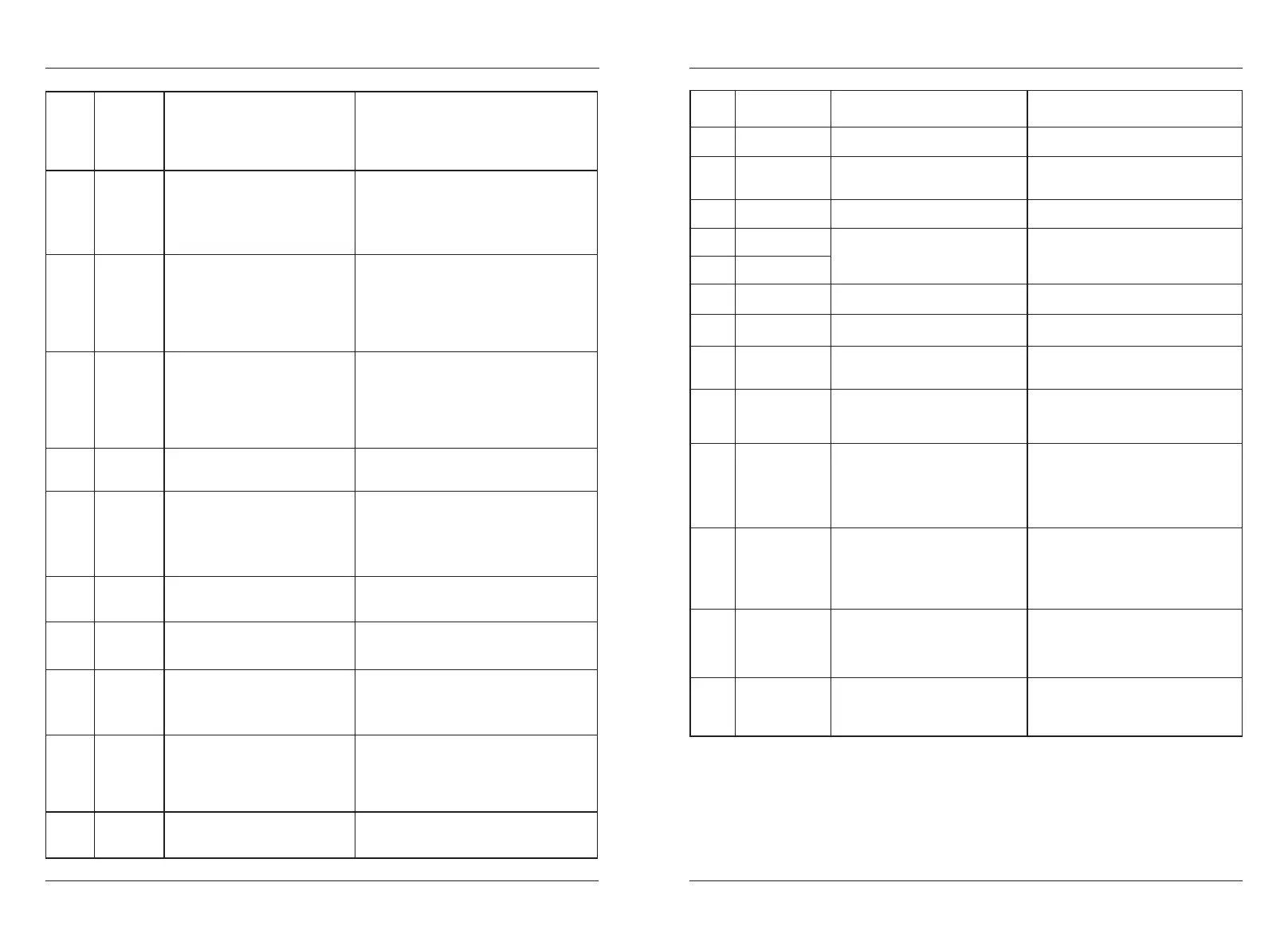

Fa ult s and s olu tio ns

EC 600 0

Fa ult s and s olu tio ns

EC 600 0

Err11

Motor

overload

1: P9-23 is set improperly.

2: The load is too heavy or

locked rotor occurs on the motor.

3: The AC drive model is of too

small power class.

1: Set it correctly.

2: Reduce the load and check the motor and

the mechanical condition.

3: Select an AC drive of higher power

class.

Err12

Power input

phase loss

1: The three-phase power input is

abnormal.

2: The drive board is faulty.

3: The lightening board is faulty.

4: The main control board is

faulty.

1: Eliminate external faults.

2: Seek technical support.

3: Seek technical support.

4: Seek technical support.

Err13

Power output

phase loss

1: The cable connecting the AC

drive and the motor is faulty.

2: The AC drive's three-phase

outputs are unbalanced when the

motor is running.

3: The drive board is faulty.

4: The module is faulty.

1: Eliminate external faults.

2: Check whether the motor three-phase

winding is normal.

3: Seek technical support.

4: Seek technical support.

Err14

Module

overheat

1: The ambient temperature is too

high.

2: The air filter is blocked.

3: The fan is damaged.

4: The thermally sensitive

resistor of the module is damaged.

5: The inverter module is damaged.

1: Lower the ambient temperature.

2: Clean the air filter.

3: Replace the damaged fan.

4: Replace the damaged thermally

sensitive resistor.

5: Replace the inverter module.

Err15

Err16

External

equipment

fault

Communi-

cation

fault

1: External fault signal is input

via S.

1: The host computer is in

abnormal state.

2: The communication cable is

faulty.

3: The communication parameters

in group PB are set improperly.

1:Reset the operation.

1: Check the cabling of host computer.

2: Check the communication cabling.

3: Set the communication parameters

properly.

Err17

Err18

Contactor

faul

Current

detection

fault

1: The drive board and power

supply are faulty.

2: The contactor is faulty.

1: The HALL device is faulty.

2: The drive board is faulty.

1: Replace the faulty drive board or

power supply board.

2: Replace the faulty contactor.

1: Replace the faulty HALL device.

2: Replace the faulty drive board.

Err19

Motor

auto-tuning

fault

1: The motor parameters are not

set according to the nameplate.

2: The motor auto-tuning times

out.

1: Set the motor parameters according

to the nameplate properly.

2: Check the cable connecting the AC

drive and the motor.

Err20

Encoder

fault

1: The encoder type is incorrect.

2: The cable connection of the

encoder is incorrect.

3: The encoder is damaged.

4: The PG card is faulty.

1: Set the encoder type correctly

based on the actual situation.

2: Eliminate external faults.

3: Replace the damaged encoder.

4: Replace the faulty PG card.

Err21

Err22

EEPROM

readwrite

fault

AC drive

hardware fault

1: The EEPROM chip is damaged.

1: Overvoltage exists.

2: Overcurrent exists.

1: Replace the main control panel.

1: Handle based on over-voltage.

2: Handle based on over-current.

Err23

Short circuit

to ground

1: The motor is short circuited

to the ground.

1: Replace the cable or motor.

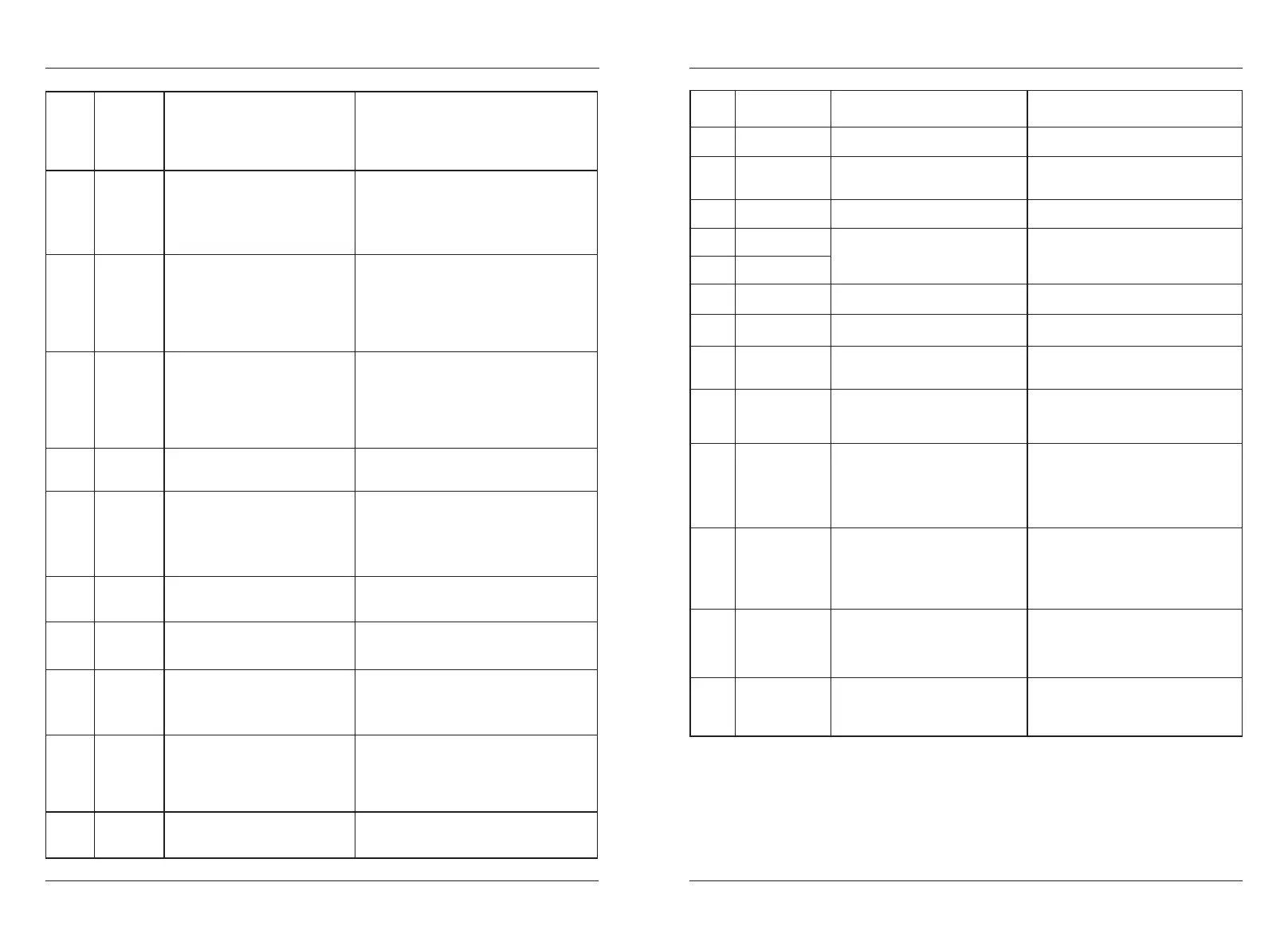

Err24

Err26

EEPORM

Initialization

fault

1: Abnormal user data.

1: Reinitialize data and set

parameters.

Running

time reached

1: Accumulative running time

reaches setting.

1: Clear the record through the

parameter initialization function.

Err29

Power-on time

reached

Err30

1: Accumulative power-ontime

reaches the setting.

1: The AC drive running current

is lower than P9-38.

1: Clear the record through the

parameter initialization function.

1: Check the load is disconnected or

P9-38 and P9-39 is correct.

Load

becoming 0

Err27

Err28

User-defined

fault 1

User-defined

fault 2

1: The user-defined fault 1 signal

is input via S.

1: Reset the operation.

Err31

Err40

PID feedback

lost during

running

Pulse-by-pulse

current

limit fault

1: The PID feedback is lower than

the setting of PA-27.

1: The load is too heavy or

lockedrotor occurs on the motor.

2: The AC drive model is of too

small power class.

1: Check the PID feedback signal or

set PA-27 to a proper value.

1: Reduce the load and check the

motor and mechanical condition.

2: Select the AC drive of higher

power class.

Err42

Err43

Too large

speed

deviation

Motor

over-speed

1: The encoder parameters are set

incorrectly.

2: The motor auto-tuning is not

performed.

3: P9-42 and P9-43 are set

incorrectly.

1: The encoder parameters are set

incorrectly.

2: The motor auto-tuning is not

performed.

3: P9-40 and P9-41 are set

incorrectly

1: Set the encoder parameters

properly.

2: Perform the motor autotuning.

3: Set F9-69 and F9-70 correctly

based on the actual situation.

1: Set the encoder parameters

properly.

2: Perform the motor auto-tuning.

3: Set P9-40 and P9-41 correctly

based on the actual situation.

Err45

Err51

Motor

overheat

Pole position

detection

failed

1: The cabling of the temperature

sensor becomes loose.

2: The motor temperature is too

high.

1: The deviation between the motor

parameters and the actual value is

too large.

1: Check the temperature sensor

cabling and eliminate the cabling

fault.

2: Lower the carrier frequency or

adopt other heat radiation measures.

1: Reconfirm whether the motor

parameters are correct, and focus on

whether the rated current is set too

small.

Loading...

Loading...