8

Instruction Leaet PUB53675

Effective December 2021

PowerXL DM1 and DM1 Pro series VFD

EATON www.eaton.com

FR2 mounting instructions

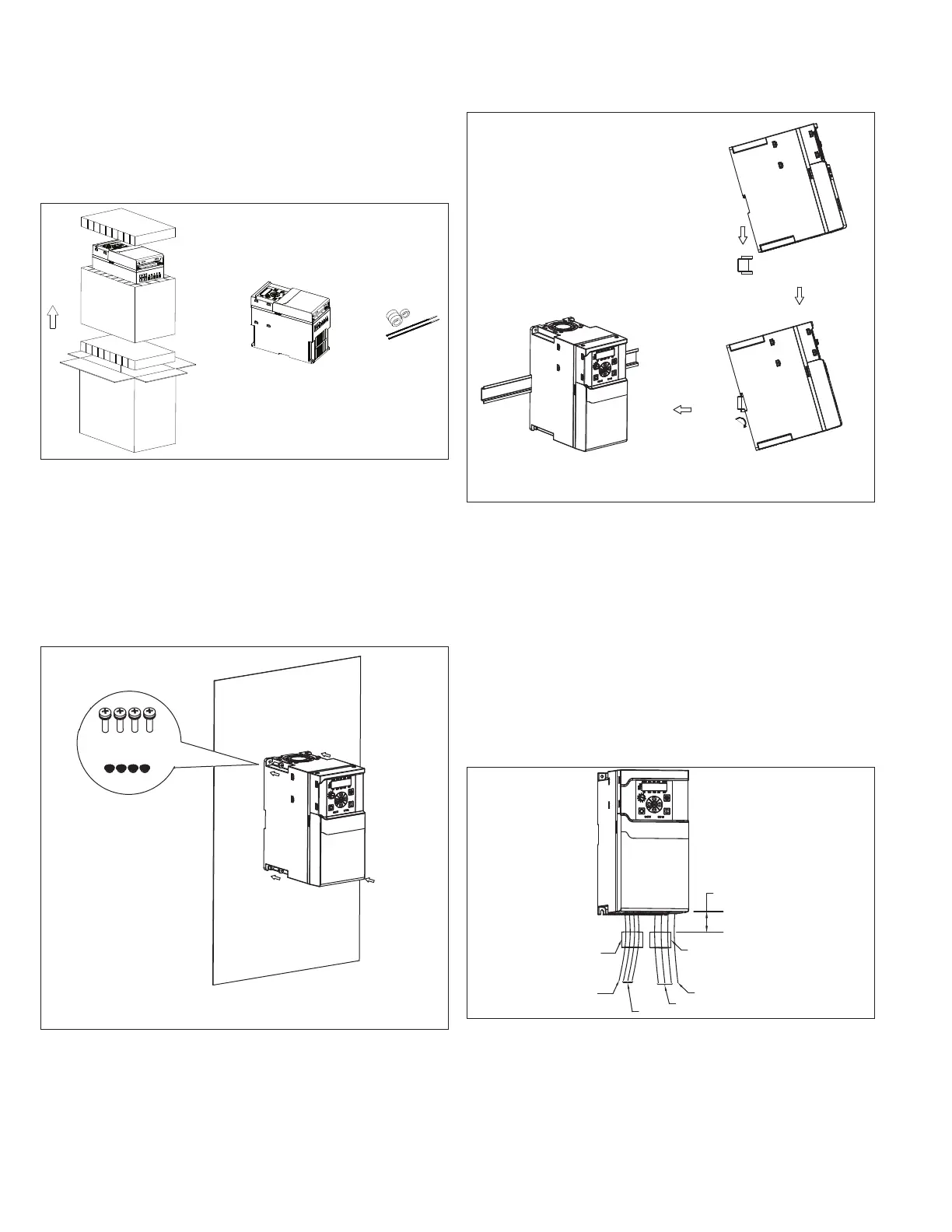

Step 1.

Lift the drive out from the carton, remove the packaging. The

magnetic cores and cable ties are only included in EMI version drive.

Step 2.

Screw mounting: Attach the drive to the mounting plate with four

M5X20 (or 3/16 in.) screws and four M5 (or 3/16 in.) nuts. The

opening dimension on the mounting plate should follow required

dimension (refer to the dimension drawing in the instruction leaflet).

DIN Rail mounting: Lift the drive at an angle about 30 degrees.

Align the top hooks of drive DIN rail mounting slot with DIN rail top

edge. Push down and rotate the drive to clip the bottom hooks on

the bottom DIN rail edge.

+

Screw mounting

Four M5x20 or 3/16 inch screws

Four M5 or 3/16 inch nuts

Torque: 3 N.m (26.6 lb/in.)

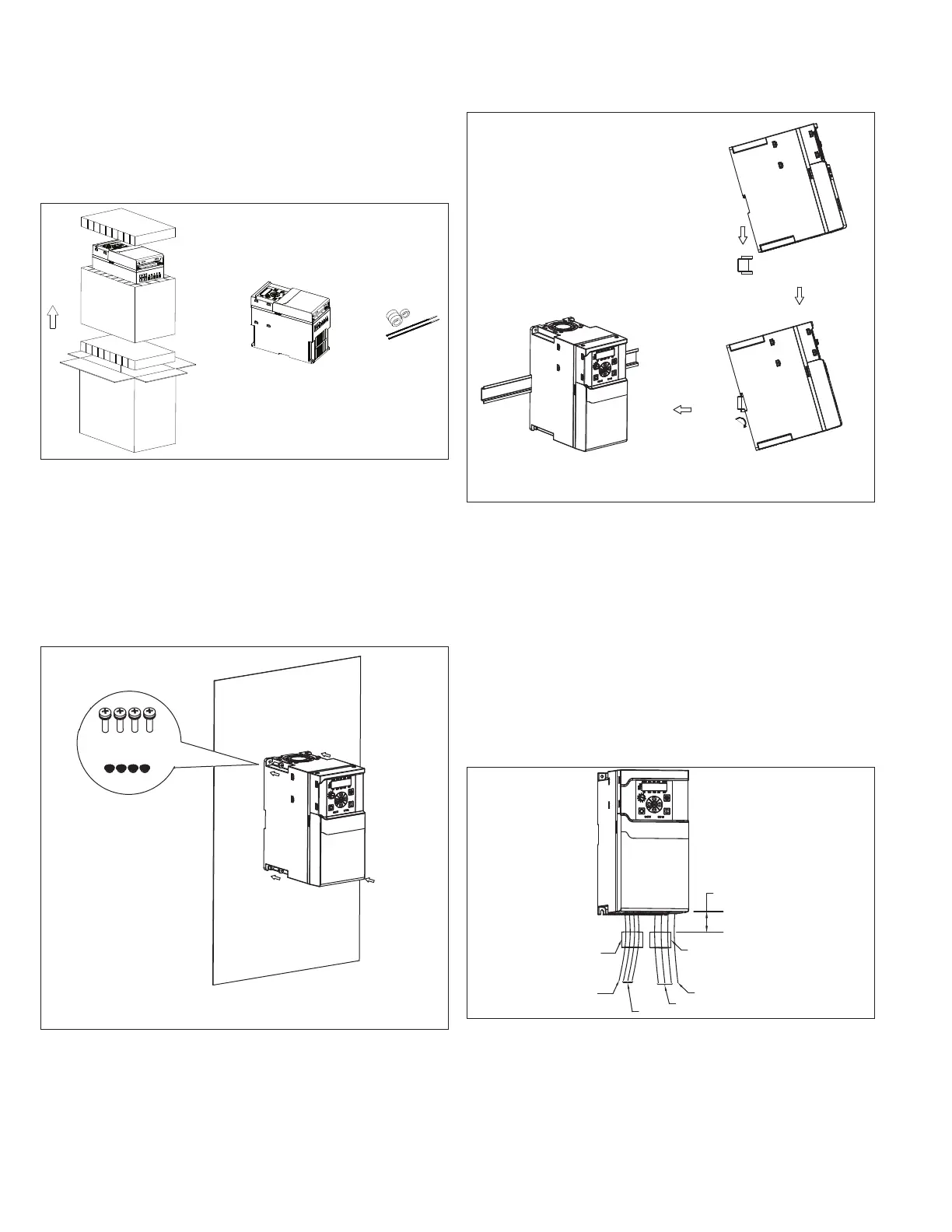

Step 3. (EMI version only):

The input wires (including 3 line wires and 1 input grounding wire)

should run through the input magnetic core before connecting to

input terminal block and grounding hole. Use a cable tie to tie the

input magnetic cores to the input wires. The output wires (only 3

motor wires) should run through the output magnetic core before

connecting to output terminal block.

The output grounding wire should not run through the output

magnetic core. Use a cable tie to tie the output magnetic cores to

the output wires. The maximum distance between input / output

magnetic cores top surface and drive bottom surface is 100 mm

(3.94 in.). The height of input magnetic core is bigger than output

magnetic core for 3 phase FR2 EMI version, but they are the same

for 1 phase FR2 EMI version.

DIN Rail mounting

3 line wires

Input grounding wire

Output grounding wire

Max. distance: 100 mm (3.94 in.)

3 motor wires

Input magnetic core

Output magnetic core

Loading...

Loading...