3) Once a year

Replace mechanical seal at an interval of one year or 6000 hours of total operating hours, either

shorter one. By the replacement, the pump life extends.

4) Once every two to five years

Overhaul of the pump assures safe and long period of operation. For the case of high frequency of

operations, early overhaul is requested.

5) Check that there is no leakage from the joint of pump and piping. When there is leakage, tighten the

connecting bolts.

6) In order to avoid the fire accident by the contact failure caused by the slack of wiring, check whether

motor connections and panel connections are not loosened.

3. Precautions during stop operation

1) When the pump is left underwater in stop-operating state, measure the insulation resistance of motor

intermittently. If there is no abnormality in the insulation resistance, operate the pump to prevent the

sliding section of the pump from rusting. When the pump is entered restarting, the procedure shall

conform to 6 "Operation".

2) When the pump is stored on ground, clean the pump and then store it at a dry site. (temperature of

storage: -5~40°C) On reusing the pump, follow the instructions of 5 "Installation" and 6

"Operation".

4. When motor protection is activated.

Check causes that motor protection is activated. After removing the causes, start the operation again.

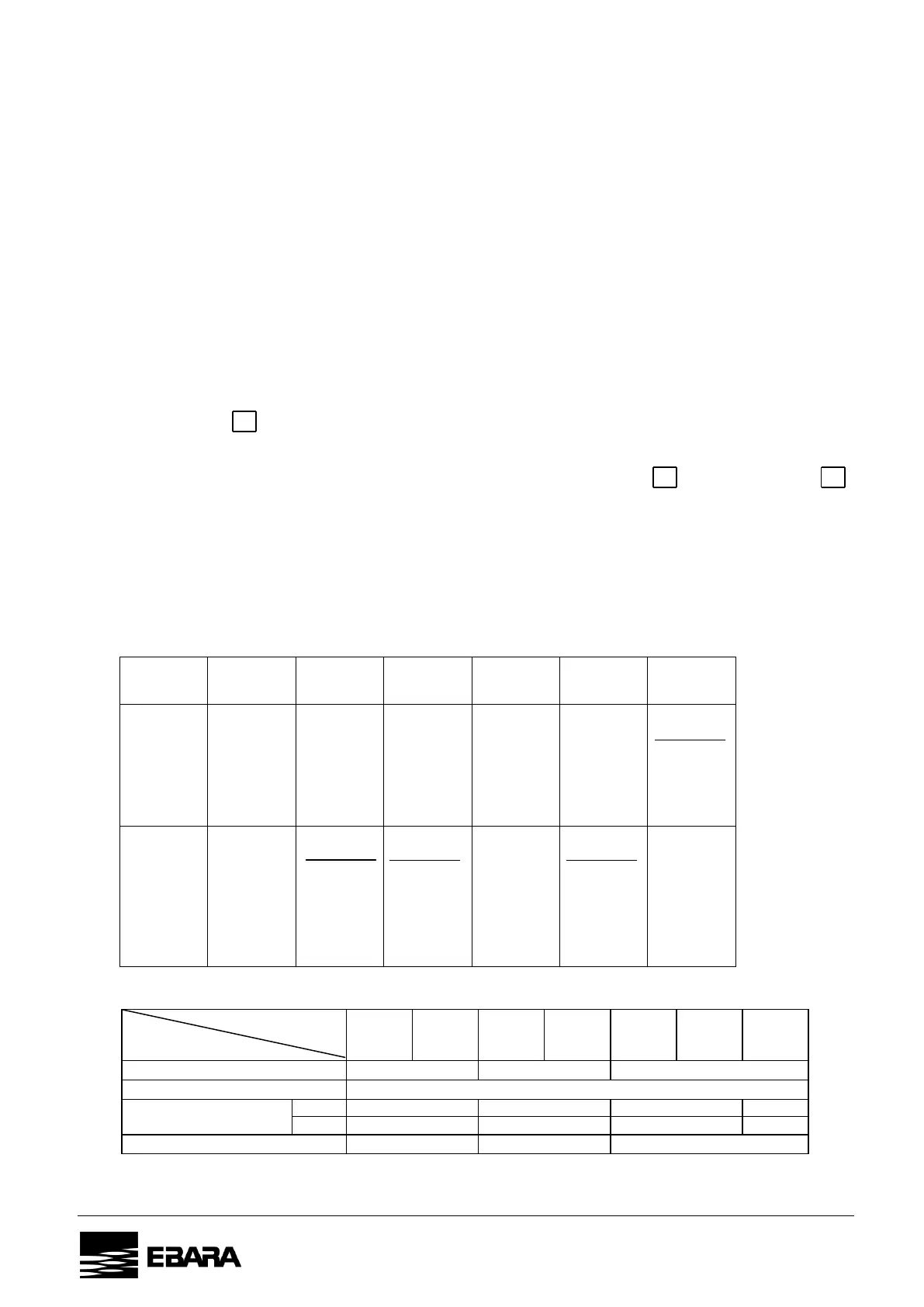

5. Consumables

1) Replace the parts when they enter the following-described condition.

Symptoms

or

approximate

period for

replacement

Oil in the

mechanical

seal

chamber

becomes

cloudy.

At every

disassembly

for

inspection.

At every oil

replacement.

Lubricant

becomes

cloudy or

blackish.

At every

disassembly

for

inspection

Expected

replacement

time

One year or

6000 hours

of total

operating

hours, either

of shorter

one.

The above-given replacement time is a standard under normal operation.

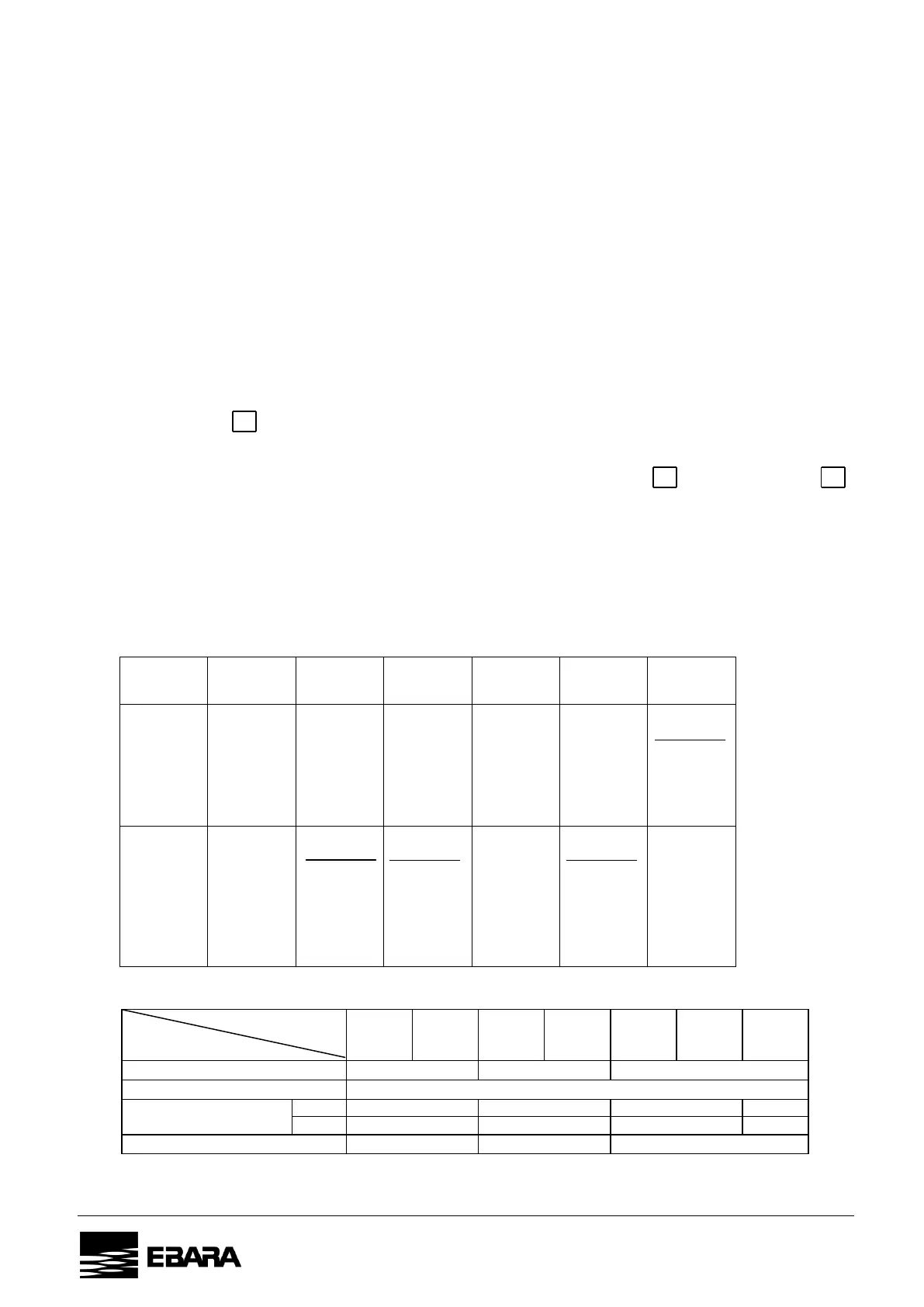

Seal washer (W12 SUS) < mm >

Φ22×Φ11.8×1.2( Outer diameter × Inner diameter × thickness)

Lubrication oil < mL >

(Turbine oil ISO VG32)

For detail of Model, etc. of individual parts, inquiry shall be given to the supplier or EBARA CORP.

Loading...

Loading...