(1) Under no circumstances should the cable be

pulled while the pump is being transported or

installed. Attach a chain or rope to the grip and

install the pump.

(2) This pump must not be installed horizontally.

Ensure that it is installed upright on a secure

base.

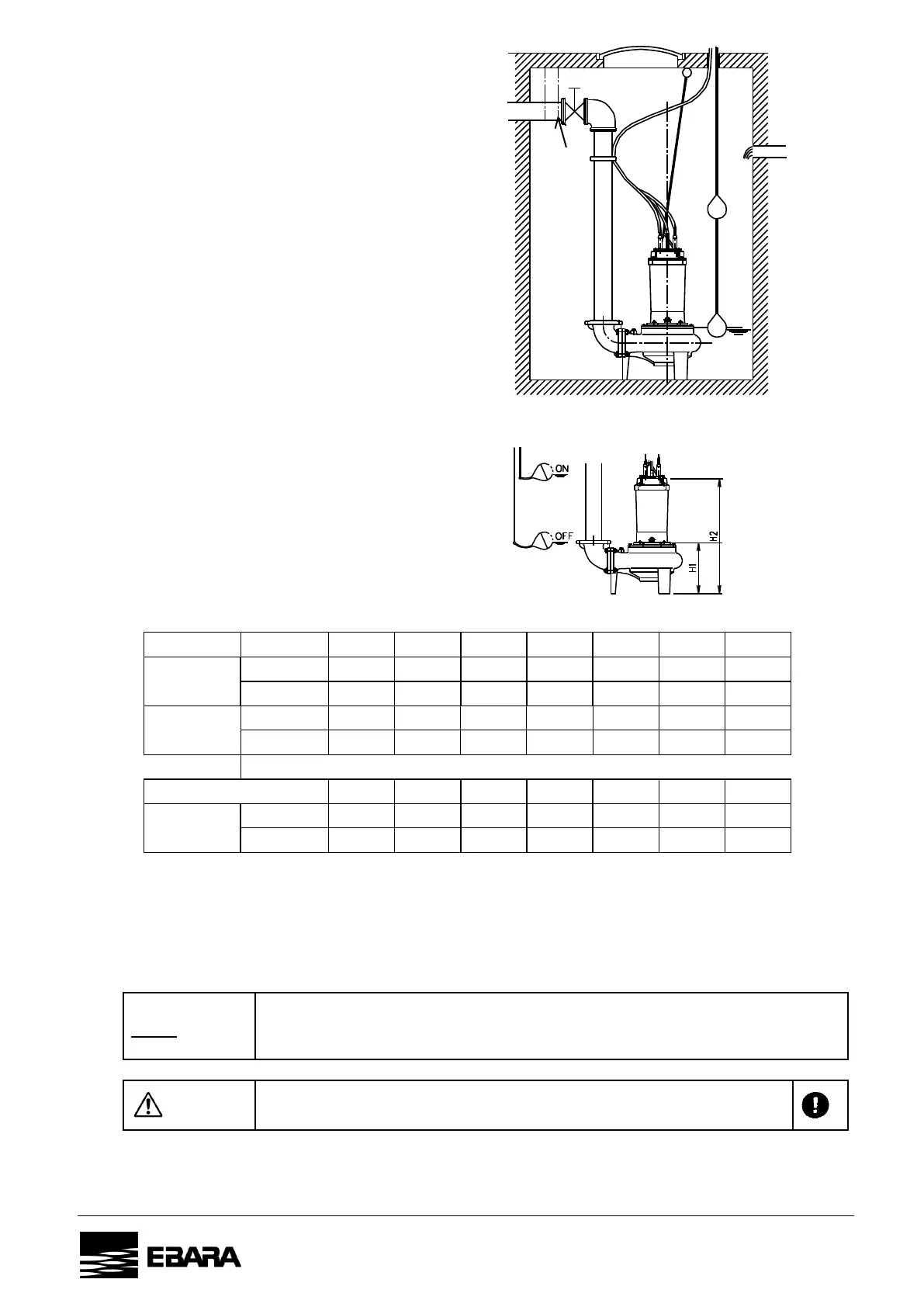

(3) Install the pump at a location in the tank where

there is the least turbulence.

(4) If there is a flow of liquid inside the tank,

support the piping to prevent abnormal

vibration. (See Fig.2)

(5) Install piping so that air will not stagnate

(6) Do not permit end of discharge piping to be

submerged. A backflow will result when the

pump is stopped.

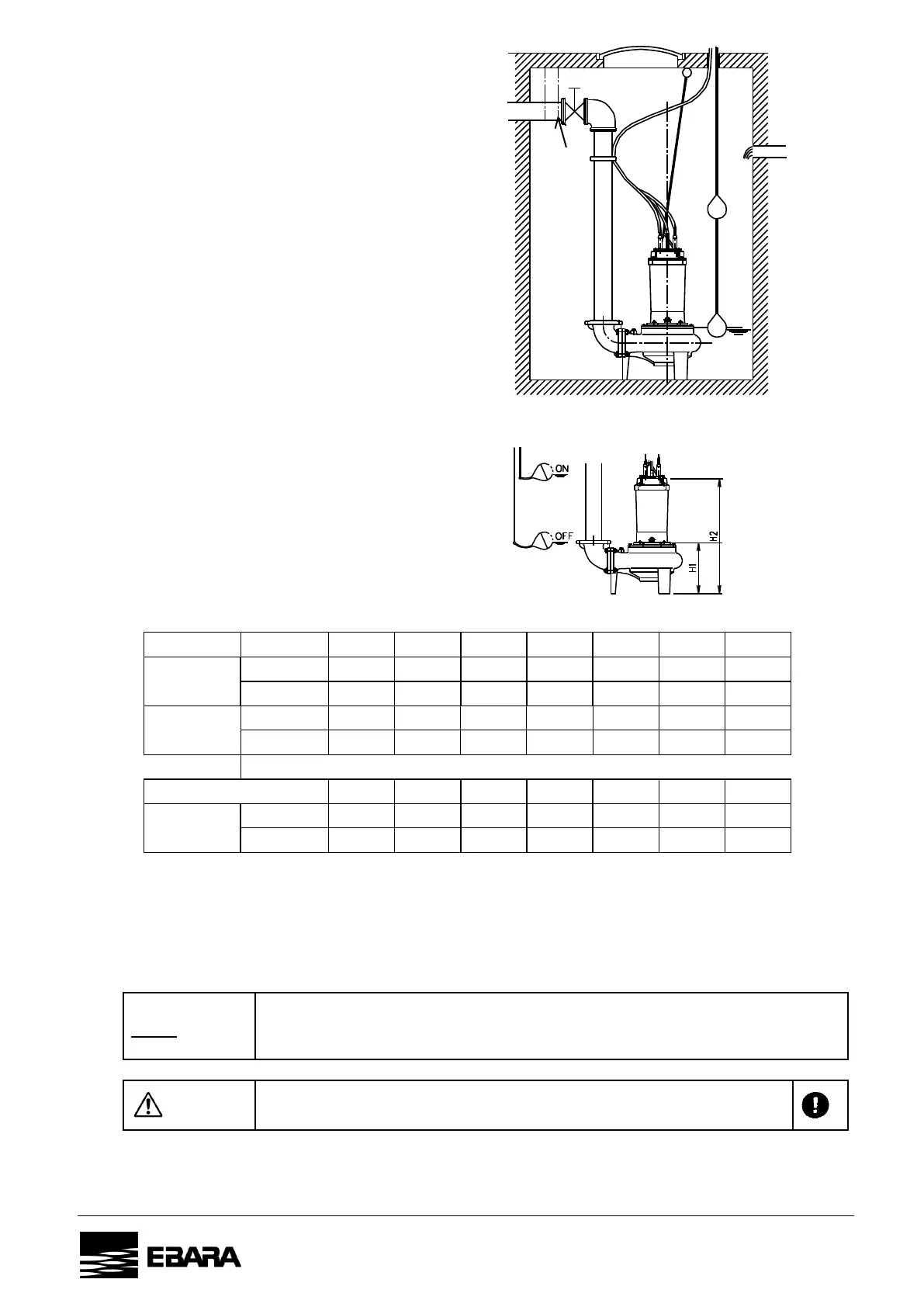

(7) Manual type pumps do not have an automatic

operating system based on built-in floats. Do

not operate the pump more than ten minutes

with the water level near the minimum

operating level as the automatic cut-off switch

incorporated inside the motor will be activated.

To avoid dry operation, install an automatic

operating system, as shown in Fig.3.

Water levels H1 and H2 are shown in the

following table.

(8) When using electrodes for automatic operating

system, incorrect actuation may occur caused

by scum and oil attached on the electrodes.

(9) Installation of the pump with quick discharge connector shall be performed according to the

manual ”Quick Discharge Connector “

Packing materials after installation, and wasted lubricant oil and grease, and parts after

inspection and repair shall be transferred to a qualified waste-treatment contractor observing

the applicable laws and the regional regulations.

Install a stand-by pump preparing for an accidental stop of the operating pump.

There is a possibility of suspension of water supply to stop the facilities.

Loading...

Loading...