54/157

SDi Decades Extreme Service Manual www.ecoer.com

May. 2023Manufacturer reserves the right to change specifications or designs without notice.

5.9.2 Insulation of drainage pipe

1.Operational procedure of refrigerant pipe insulation

Select the suitable pipe → insulation (except joint section) → piping layout and connection→ drainage test→ insulate

the joint parts

2. Purpose of drainage pipe insulation

The temperature of condensate drainage water is very cold. If insulation is not enough, it shall form dew and

cause leakage to damage the house decoration.

3. Insulation material selection for drainage pipe

• The insulation material should be flame retardant material, the flame retardancy of the material should be

selected according to the local law.

• Thickness of insulation layer is usually above 0.39inch.

• Use specific glue to paste the seam of insulation ma- terial, and then bind with adhesive tape. The width

of tape shall not be less than 1.96inch. Make sure it is firm and avoid dew.

4. Installation and highlights of insulation construction

• The single pipe should be insulated before connecting to another pipe, the joint part should be insulated

after the drainage test.

• There should be no insulation gap between the insulation material.

4. Installation highlights of insulation construction

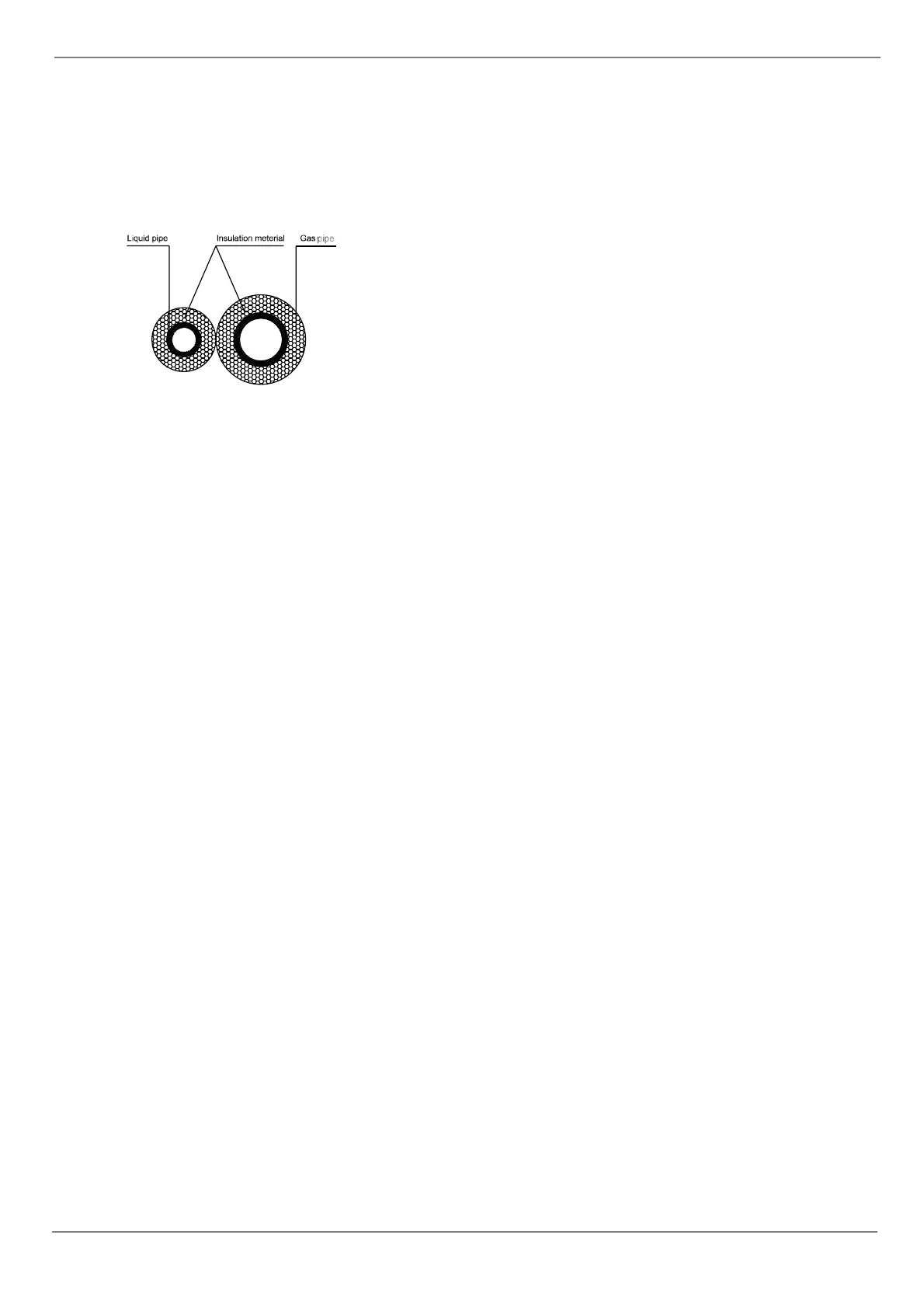

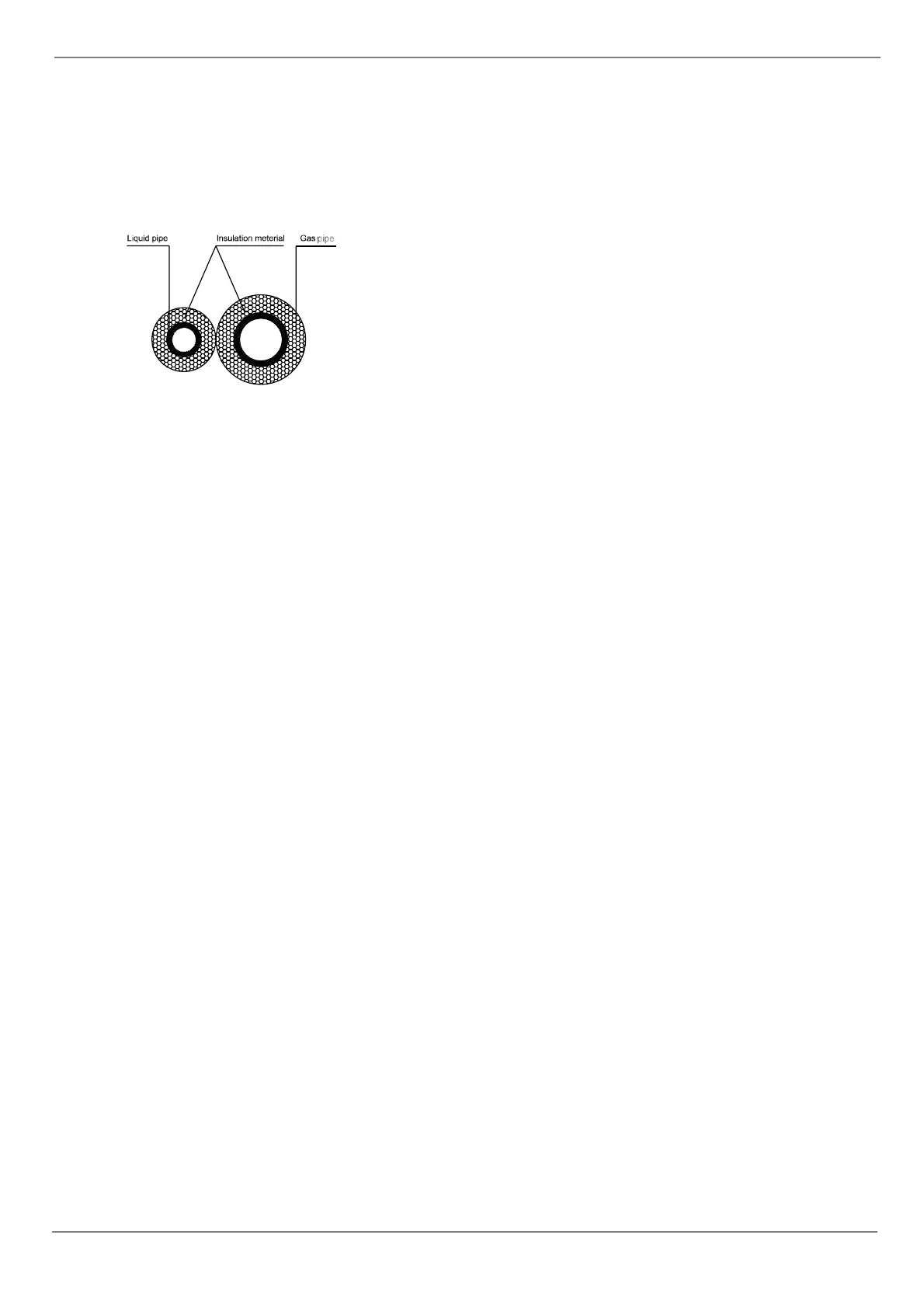

• Gas pipe and liquid pipe shall be insulated separately, if the gas pipe and liquid pipe were insulated

together; it will decrease the performance of air conditioner.

• The insulation material at the joint pipe shall be 1.96~3.93inch longer than the ga p of the insulation

material.

• The insulation material at the joint pipe shall be inserted into the gap of the insulation material.

• The insulation material at the joint pipe shall be banded to the gap pipe and liquid pipe tightly.

• The linking part should be use glue to paste together.

• Be sure not bind the insulation material overtight, it may extrude out the air in the material to cause bad

insulation and cause easy aging of the material.

Loading...

Loading...