4- VACUUM GAUGE PORT

5- PRESSURE ADJUSTMENT

6- TO NOZZLE

The pump is adjusted during testing and inspection to 12 bar. VERIFY: - That piping system is perfectly sealed; - That the use

of hoses is avoided whenever is possible (use copper pipes preferably); - That depression is not greater than 0,45 bar, to avoid

pump’s cavitation; - That check valve is suitably designed for the duty; The pump pressure is set at a value of 12 bar during the

testing of burners. Before starting the burner, bleed the air in the pump through the gauge port. Fill the piping with light-oil to

facilitate the pump priming. Start the burner and check the pump feeding pressure. In case the pump priming does not take place

during the first prepurging, with a consequent, subsequent lock-out of the burner, rearm the burner’s lock-out to restart, by

pushing the button on the control box. If, after a successful pump priming, the burner locks-out after the prepurging, due to a fuel

pressure drop in the pump, rearm the burner’s lock-out to restart the burner. Do not allow the pump to work without oil for more

than three minutes. NOTE: Before starting the burner, check that the return pipe is open. An eventual obstruction could

damage the pump sealing device.

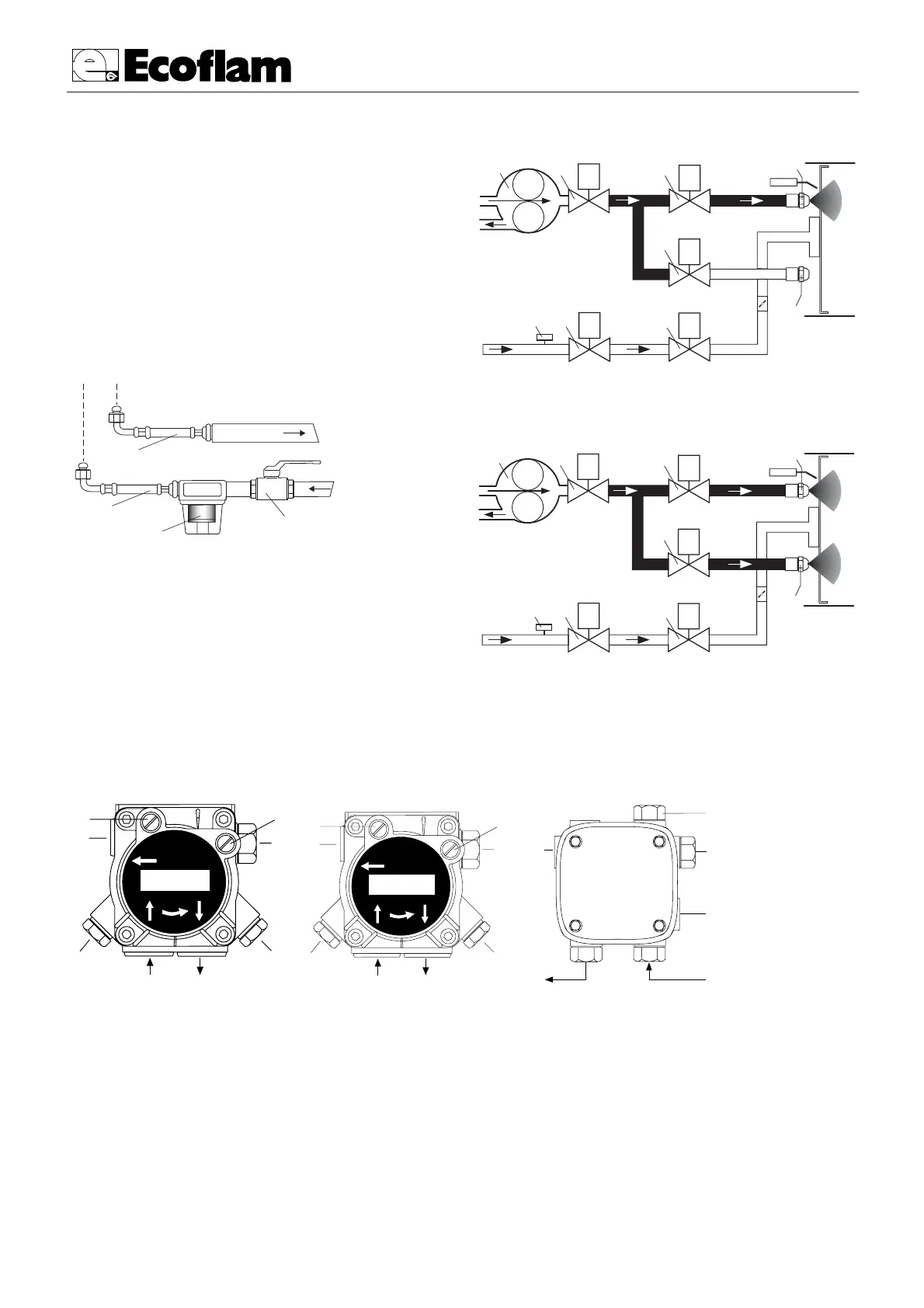

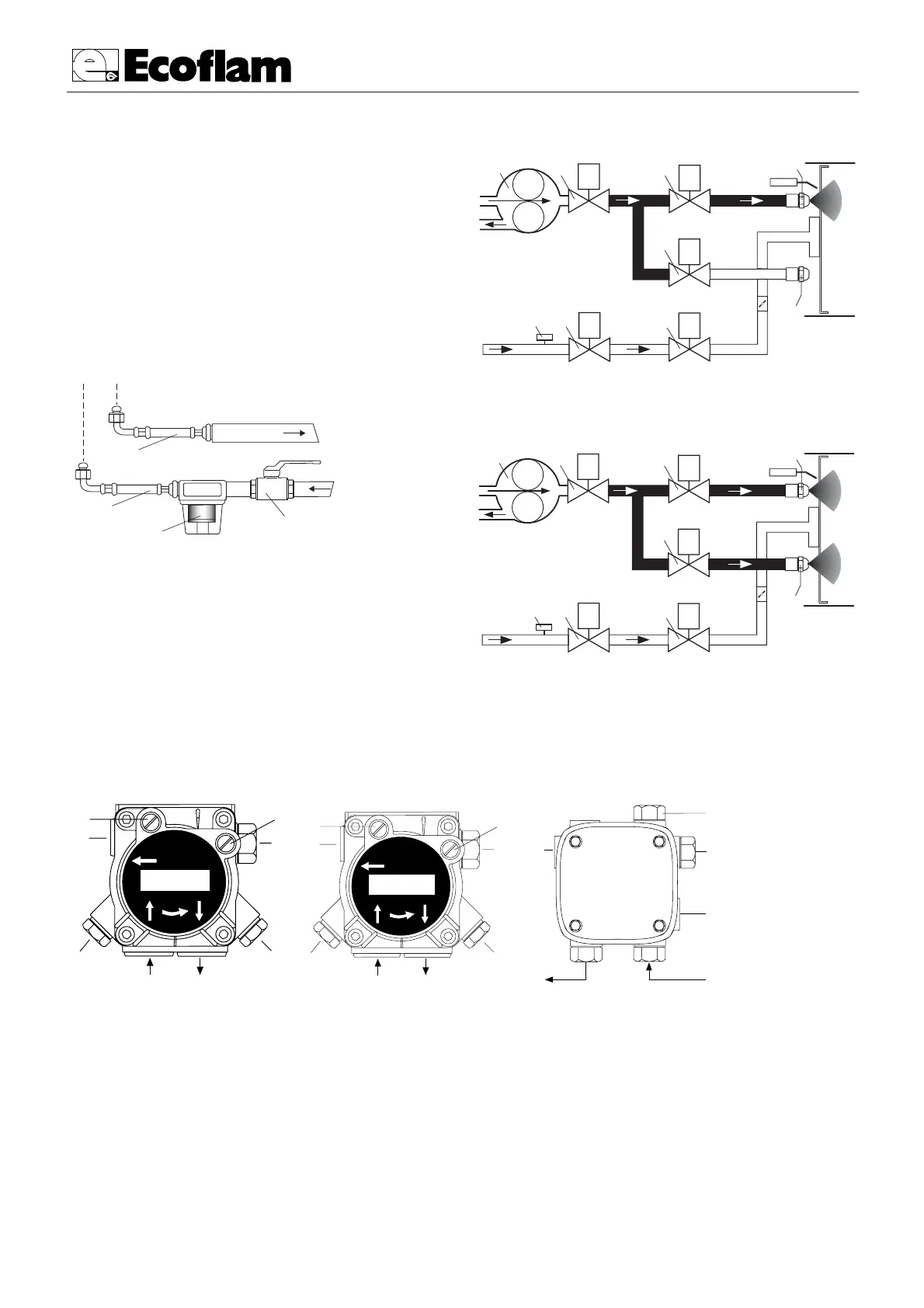

LIGHT-OIL CIRCUIT

A - HOSE

B - OIL FILTER

C - OIL COCK

1 - PUMP

2 - SAFETY OIL VALVE

3 - LOW FLAME OIL VALVE

4 - HIGH FLAME OIL VALVE

5 - LOW FLAME NOZZLE

6 - HIGH FLAME NOZZLE

7-GAS PRESSURE SWITCH

8-SAFETY GAS VALVE

9-GAS VALVE

SUCTION

RETURN

SUCTION

RETURN

Adjust light-oil pressure and airflow for the low flame.

The burner will operate in Low flame until the switch set again

to High flame. The control box will then enable the High

flame, through the full opening of the air damper.

The High flame pressure, in normal operation, must be set to

12-15 bar (check on the manometer connected to the pressure

port). Adjust the combustion air through the head adjusting

lever.

A

A

B

C

1- INLET

2- RETURN

3- BLEED AND PRESSURE GAUGE PORT

Loading...

Loading...