M561-00-880 Issue C

Page 50 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

Use the following procedure to change the gas module mode:

1. Access the Config menu on the PDT (contact Edwards for advice).

2. Scroll down to Gas Process - press ENTER.

3. Scroll through options to choose gas process - use ENTER to select desired option.

4. Scroll down to Default N2 Setup - press ENTER.

5. PDT displays: Set Default Yes (Press Enter) - confirm default - Press ENTER.

5.6.3 iXL variants

iXL variants are not fitted with gas modules.

5.7 System operating temperature configuration

The system operating temperature configuration may be adjusted to suit process demands. Contact Edwards service

personnel for instructions on how to access the configuration menu (via the PDT) and for process-specific

recommendations.

Use the following procedure:

1. Access the Config menu on the PDT (requires an access code, contact Edwards).

2. Scroll to Temp Setpoints – press ENTER.

3. Scroll to Set DP Temp or Set MB Temp – press ENTER.

4. Scroll to desired temperature – Press ENTER.

Notes: 1 The Dry Pump set point is the desired surface temperature of the internal low vacuum stage.

2 The Booster set point is the temperature of the booster stator at which additional cooling is deployed

to control booster temperatures. The booster will not necessarily reach the set point temperature at

ultimate conditions.

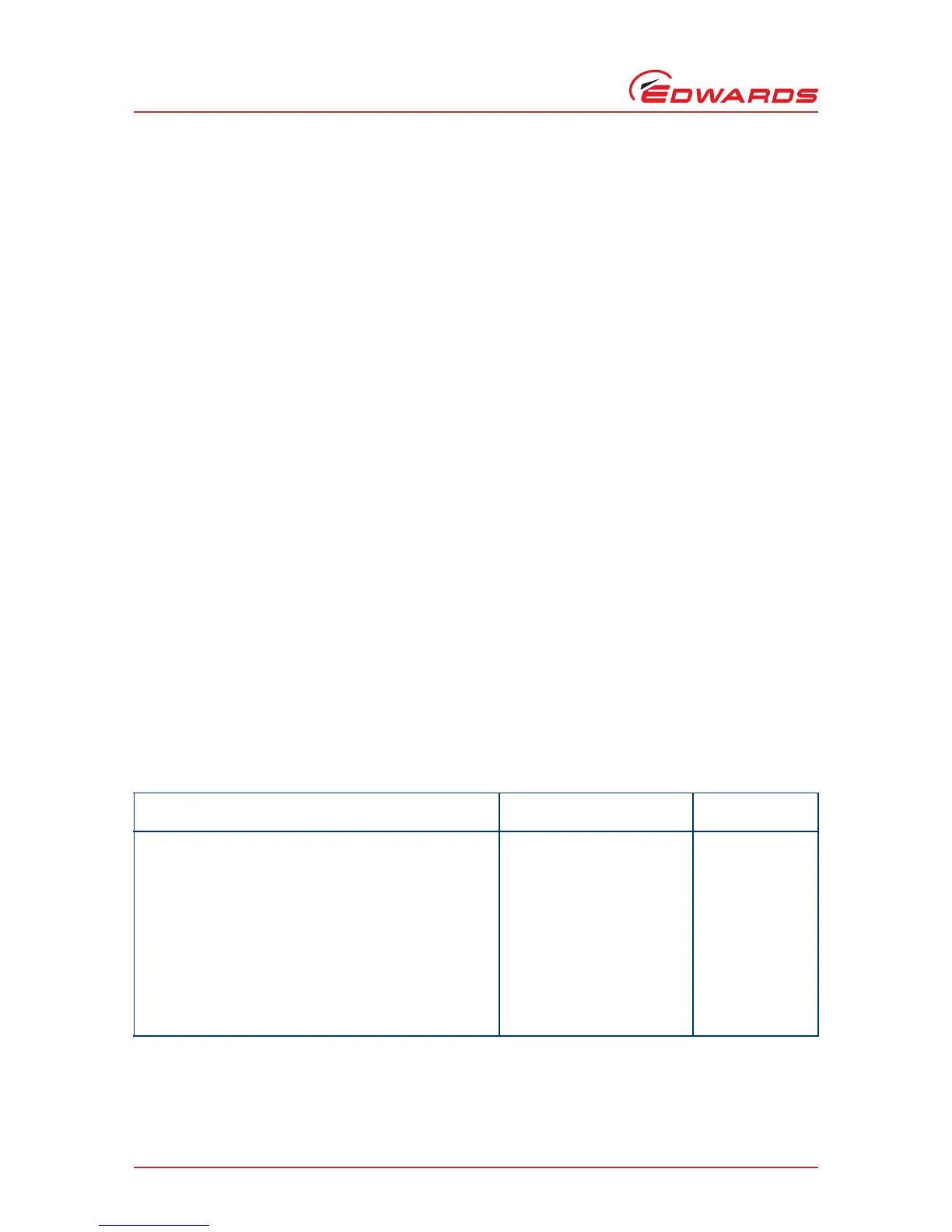

Refer to Table 21 for default temperature settings and ranges.

Table 21 - Dry pump and booster temperature settings

Temperature Setting

Range in which temperature

can be set (°C)

Default value (°C)

Standard iXH dry pump 70 - 135 110

iXH T variants containing 450H and 500H dry pump 110 - 150 140

iXH3030T 110 - 160 160

All other iXH T variants 110 - 150 150

iXL250Q dry pumps - 105

iXL 500 dry pumps 126 - 136 131

iXL750Q dry pumps - 120

Booster (except iXH610) 60 - 100 100

Booster (iXH610 only) 0 - 55 55

Loading...

Loading...