How-To: Using the IQ-501 with the Fiery server

4

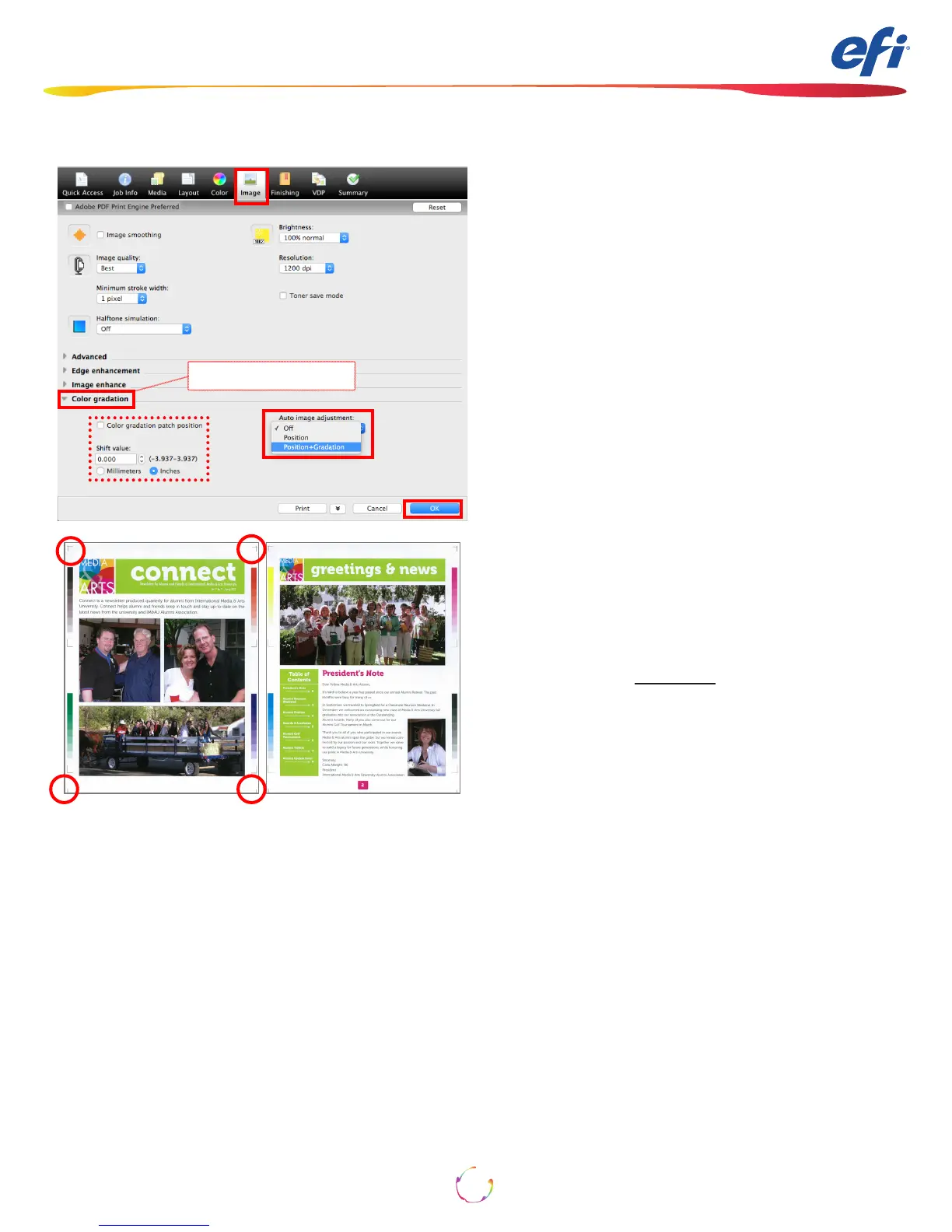

1. Open Job Properties of the job in which you

wish to engage Auto Image Adjustment.

2. Select the Image tab.

Note that on some software versions the Auto

Image Adjustment may be in the Job Info tab or

directly under the Image tab

3. Pull down the Color Gradation section

or Realtime Adjustment section.

4. Select either Position or Position+Gradation.

5. OPTIONAL: check the Color gradation patch

position check box and choose a +/- Shift value

to ne tune the placement of the color bars on

the edge of the sheet.

6. Click OK.

7. Print the job.

8. Follow directions as needed on the Press Control

Panel.

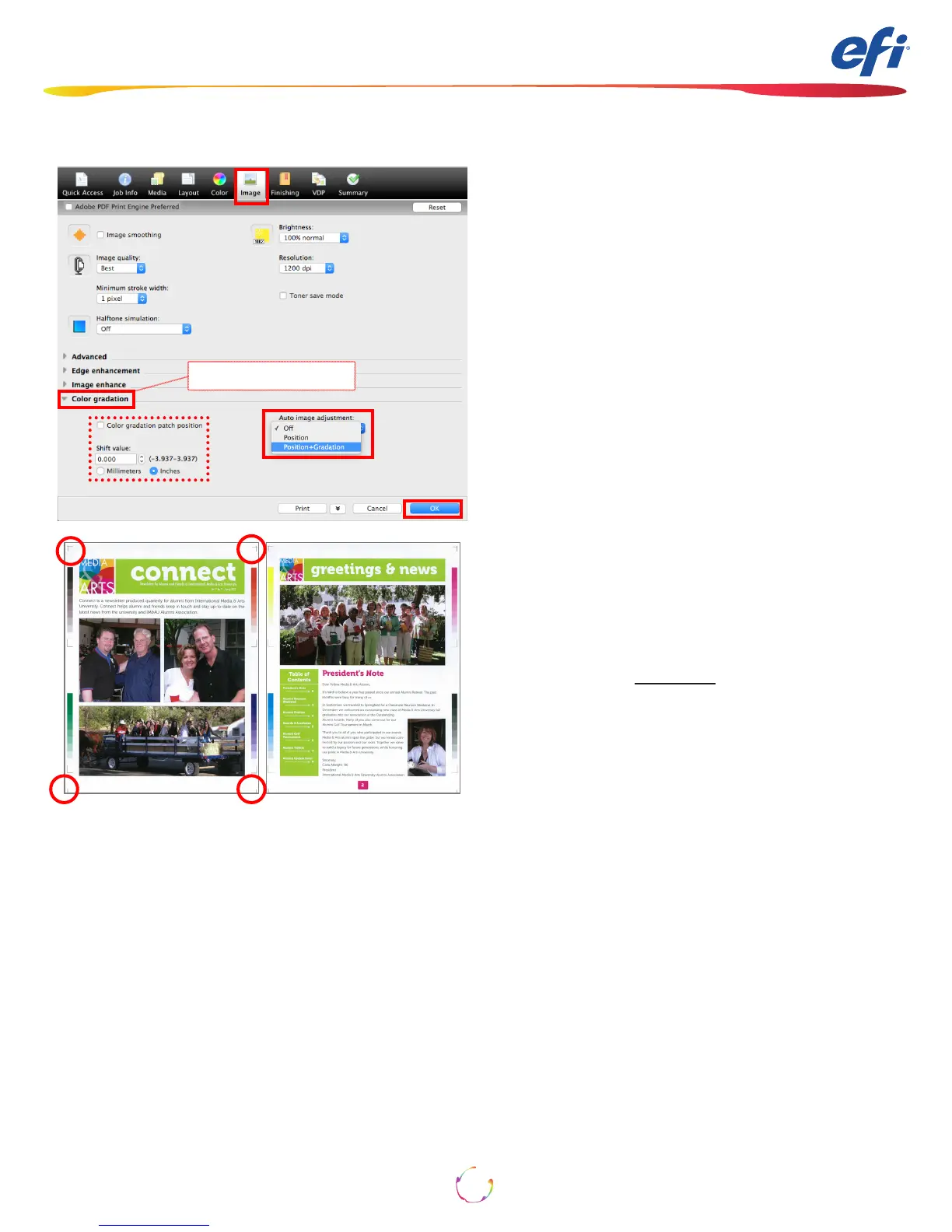

For the Position+Gradation selection the engine

places alternating CMYK and RGB/Process K

strips on the sheets’ inboard and outboard edges.

Approximately 9mm per edge is used. Position

places cross hair marks within the 9mm edge at

each corner. Please ensure that user content is

not placed in these border areas as the engine will

override and knock out content.

Note: ImageViewer or Preview will not show these

marks as they are added at the engine.

Note2: If the position marks or color bar strips do

not appear please contact Konica Minolta service

in order to resolve.

RGB/Process K strips CMYK strips

The engine keeps track of which set of strips were

last printed and ensures that they alternate.

Position markers shown in red circles.

Auto Image Adjustment

or Real time adjustment

Loading...

Loading...