22

4. Remove the retainer/wash from the liquid end,

and insert the installation tool/dowel pin into

the liquid end through the piston seal (if your

pump uses a 3/32” or 1/8” diameter piston, the

installation tool has a “hooked” end, which is

used to remove the seals). If you are using the

installation tool, hook the existing seals and

remove and discard both the washer and the

seal. If you are using the ¼” dowel pin, rock

the dowel pin back and forth gently, and

remove and discard both the washer and seal.

Do not scratch the walls of the piston seal gland

in the liquid cylinder with the tool/dowel pin.

5. Inspect the piston. You can remove the piston by moving the piston up in the slot which holds it in

place. If the piston has scratches on the sapphire, or significant corrosion on the stainless steel piston

holder, you should replace it. If there is minor corrosion on the piston holder, clean the piston holder.

Also inspect for evidence of deposits on the sapphire. If deposits are present on the sapphire

(discoloration or particulates), clean it. If the sapphire does not clean, you should replace the piston.

6. Inspect the retainer. Clean the retainer/wash if necessary. If there is evidence of wear, or if the piston

does not fit snugly in the retainer/wash, or if the retainer/wash grips the piston too tightly, you should

replace the retainer/wash.

7. Inspect the liquid cylinder, paying special attention to the gland for the piston seal. Any scratches or

irregularities will require replacement of the liquid end.

8. Clean all parts with a liquid detergent, followed by a rinse. Clean any fluid in the mechanical end of the

pump.

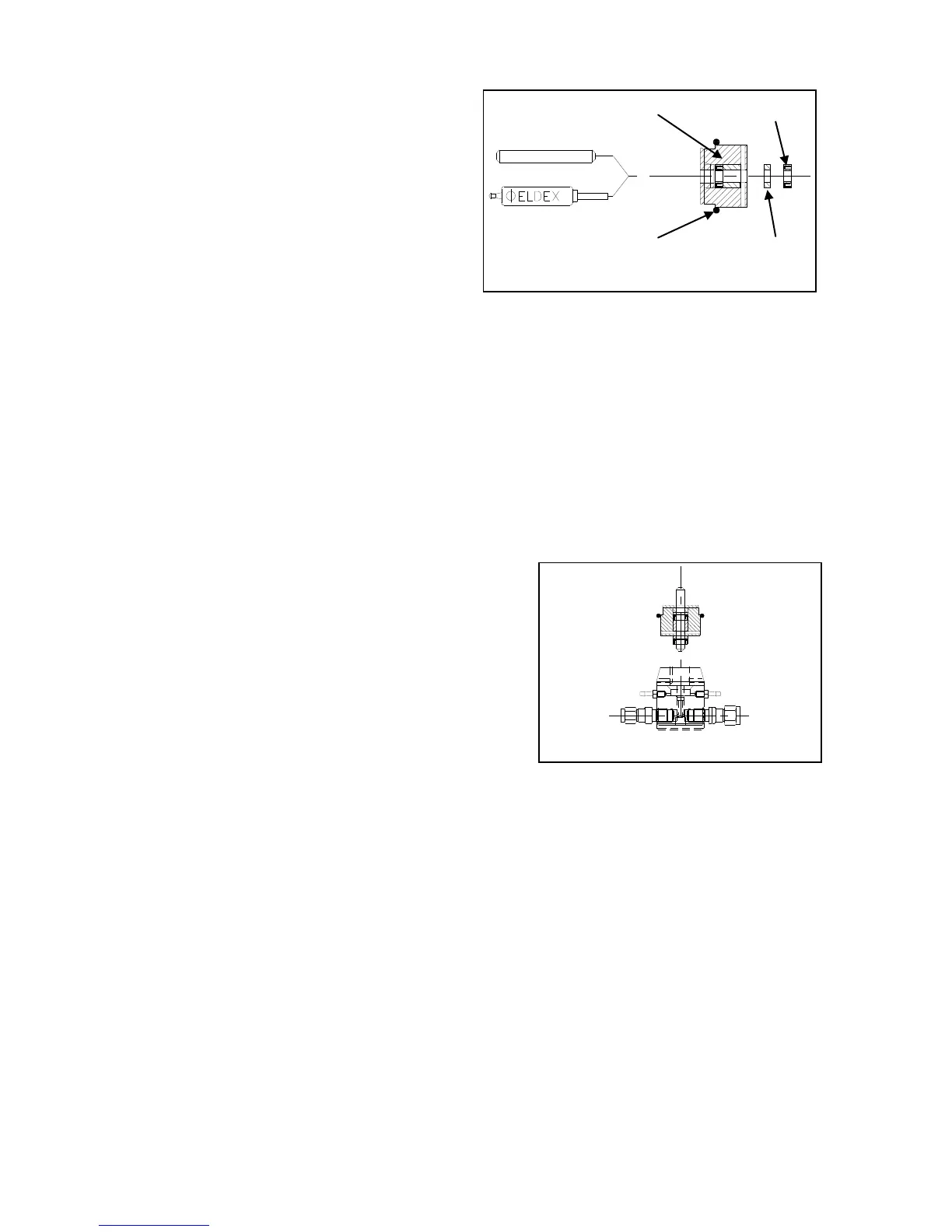

9. Insert the installation tool/dowel pin into the

retainer/wash and then into the new seal backup washer

(used on 1HI, 2HI, and 3HI pumps) and new piston seal.

When inserting the tool through the new piston seal, the

piston seal should lay flat on a hard surface with the

spring side down (the seal will generally “snap” onto the

tool). Position the parts on the tool in the order shown.

Insert the tool into the liquid end bore. CAUTION:

The open side of the seal (side revealing the spring or

the O ring) should face the closed (fluid side) end of the

liquid end.

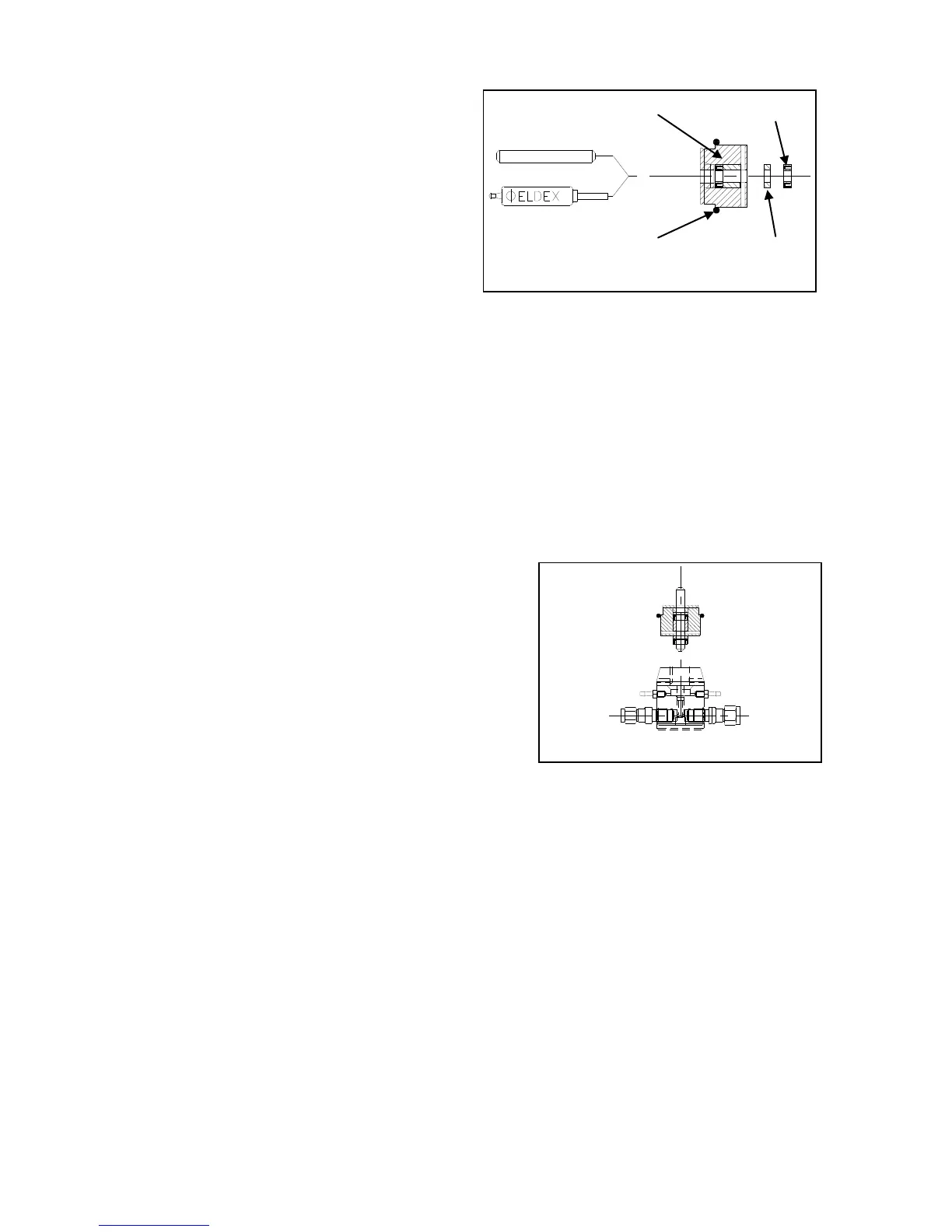

10. Keeping the tool perpendicular with the face of the liquid end, push the piston seal and washer into the

liquid end bore, by pressing down gently and evenly on the edge of the retainer/wash with both thumbs.

11. Withdraw the tool, while holding the retainer/wash and liquid end firmly in place. When installing the

retainer/wash, make sure you line up the holes in the retainer with the wash system.

12. Reinstall the liquid end on the pump. See Figure 4.1.

PRECAUTIONS:

1. Do not re-use the old piston seal.

2. Cleanliness is very important for optimal seal and check valve operation.

3. Note suggestion regarding seal “break-in” on page 15.

NOTE: If you retain the tools supplied with Eldex Part Nos. 5911, 5941, or 5944, you can purchase just the

seals and re-use the tools.

Figure 4.2: Piston Seal Assembly

Figure 4.3: Piston Seal Replacement

Loading...

Loading...