23

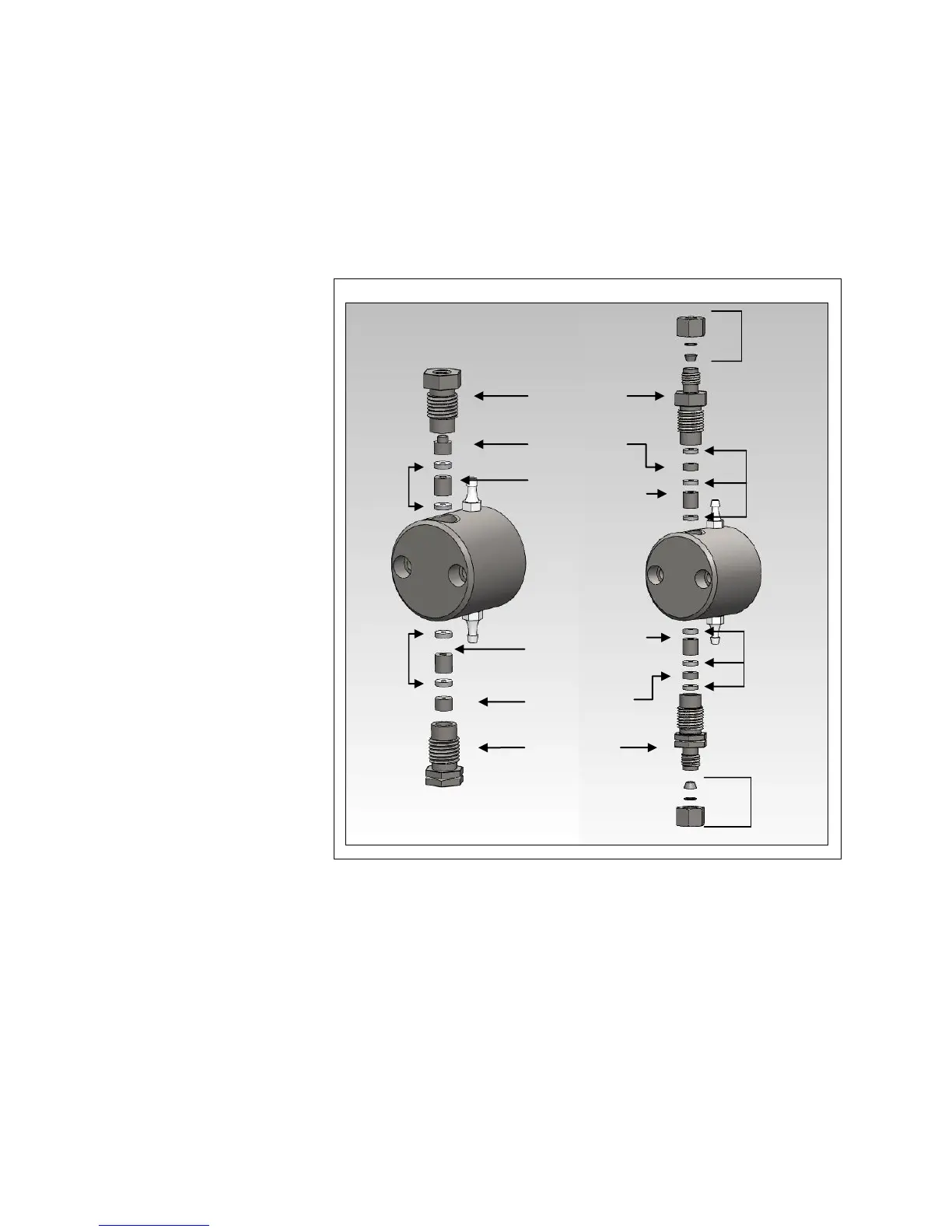

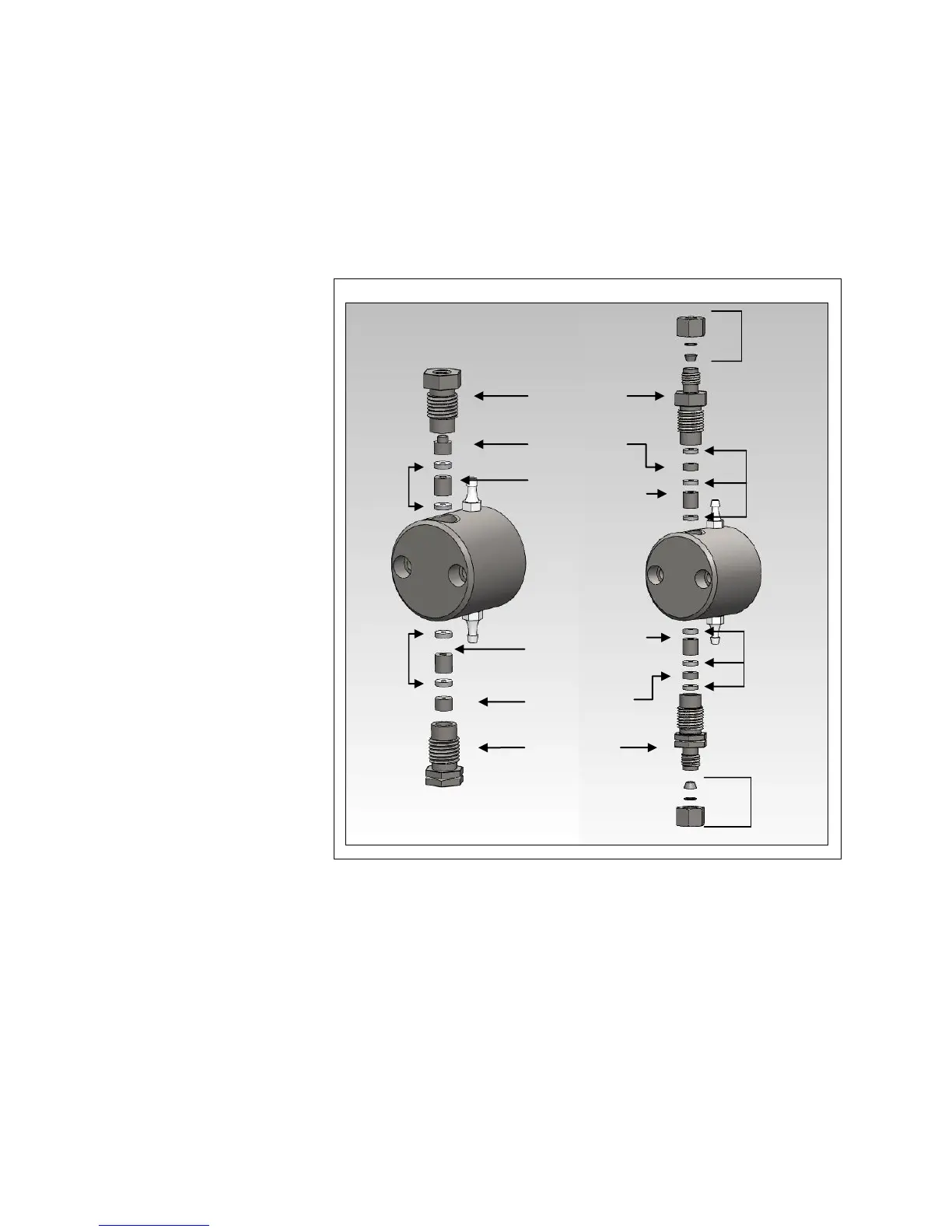

Replacing Valves

Always replace valves in a clean area to prevent dust and dirt from entering the pump.

Removal of Existing Valves

The valves are the two hexagon-shaped components on the liquid end assembly (see Figure 4.4). Inlet valves

can be distinguished from outlet valves by the groove on the hexagonal part of the valve. Remove the valves

with a ½” wrench, turning in a counter-clockwise direction. After removal, be careful to keep the valve oriented

so the translucent washers face upwards to prevent parts from falling out. If you wish to replace the cartridge in

the valve, you may purchase

replacement cartridges,

which include the cartridge

and instructions.

Installation of New

Valves

1. Inlet valves can be

distinguished from

outlet valves by the

groove on the

hexagonal part of

the valve.

2. Unscrew the

shipping nut and

remove the metal

shipping washer, as

these are not used

for installation of

the valves.

3. Insert the new valve

into the liquid end

assembly and

tighten by hand

until just finger-

tight. Then use a

½” wrench and

tighten ¼ turn more.

You should tighten

valves to the point

at which no further

leakage occurs, or

not more than 4.5

ft./lbs.

OVERTIGHTENING THE VALVES CAN CAUSE THE SAPPHIRE SEATS TO CRACK.

STABILIZE THE VALVE WITH A ½” WRENCH WHEN ATTACHING YOUR FITTINGS TO PREVENT

FURTHER VALVE TIGHTENING. DO NOT TIGHTEN FITTINGS TO BEYOND 40 IN./LBS., OR THE

POINT WHERE NO FURTHER LEAKAGE OCCURS.

Replacing Valve Cartridges

1. Remove the valve from the cylinder (see above for detailed instructions).

2. Using the smaller dowel pin provided (1-1/4” long by 1/8”diameter), press out the internal components

of the valve assembly using a steady pressure. Do not hammer parts through with the dowel pin or

hammer on the dowel pin. Do not allow the valve parts to fall out of the valve onto a hard surface.

Figure 4.4: Liquid End Assembly

Valve Cartridge:

Triangular Opening

faces up

Valve Cartridge:

Triangular Opening

faces up

Loading...

Loading...