33

APPENDIX

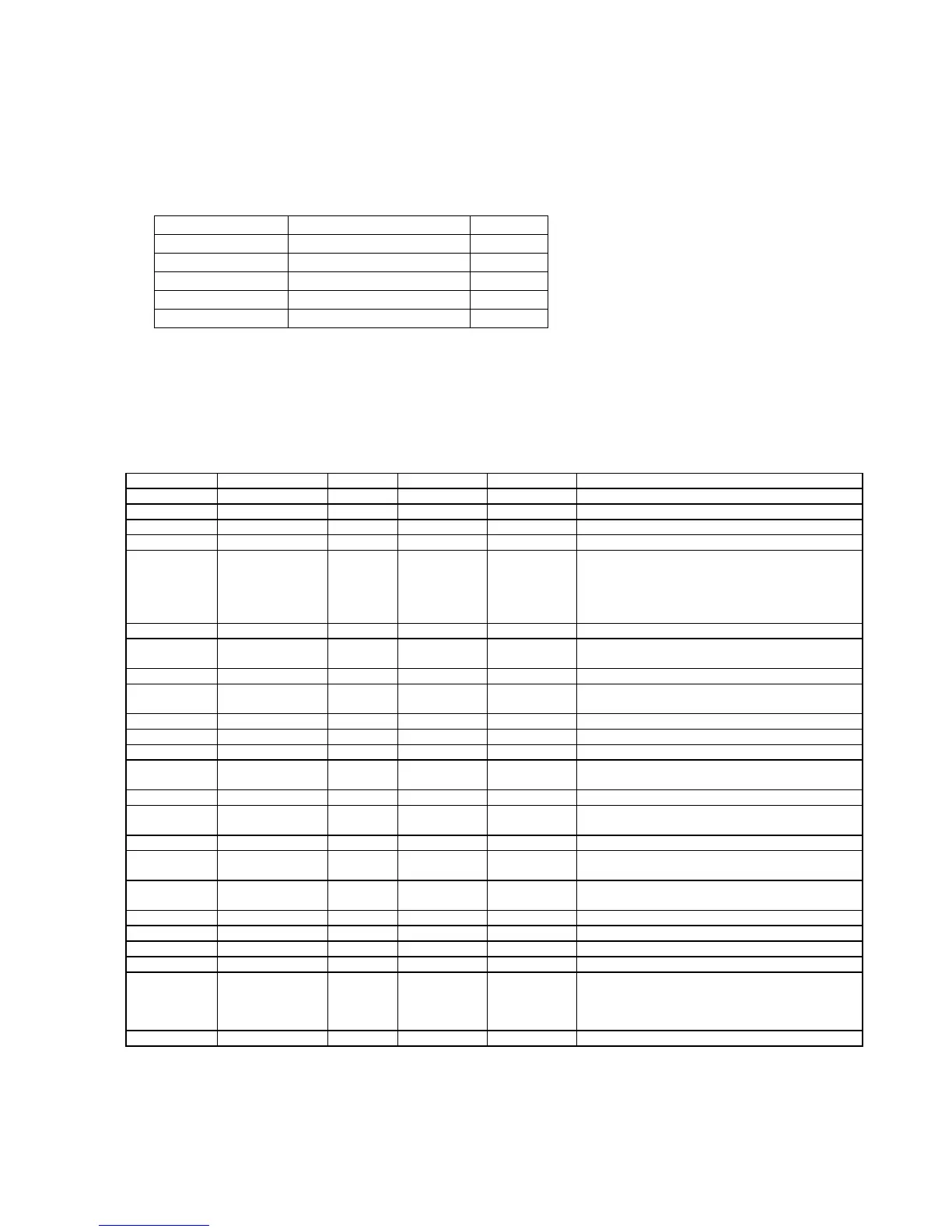

RS232

An RS232C modular jack (connector is RJ-11) is on the rear panel. It is configured for 9600 baud, 8 data

bits, 1 stop bit, and no parity. Pinout is:

The pump uses hardware handshaking. The pump does not transmit on the TXD output if the DSR input is

at a low logic level. The pump does not receive on the RXD input when the DTR output is at a low logic

level. A low logic level is –3.0 to –15 volts, and a high logic level is 3.0 to 15 volts.

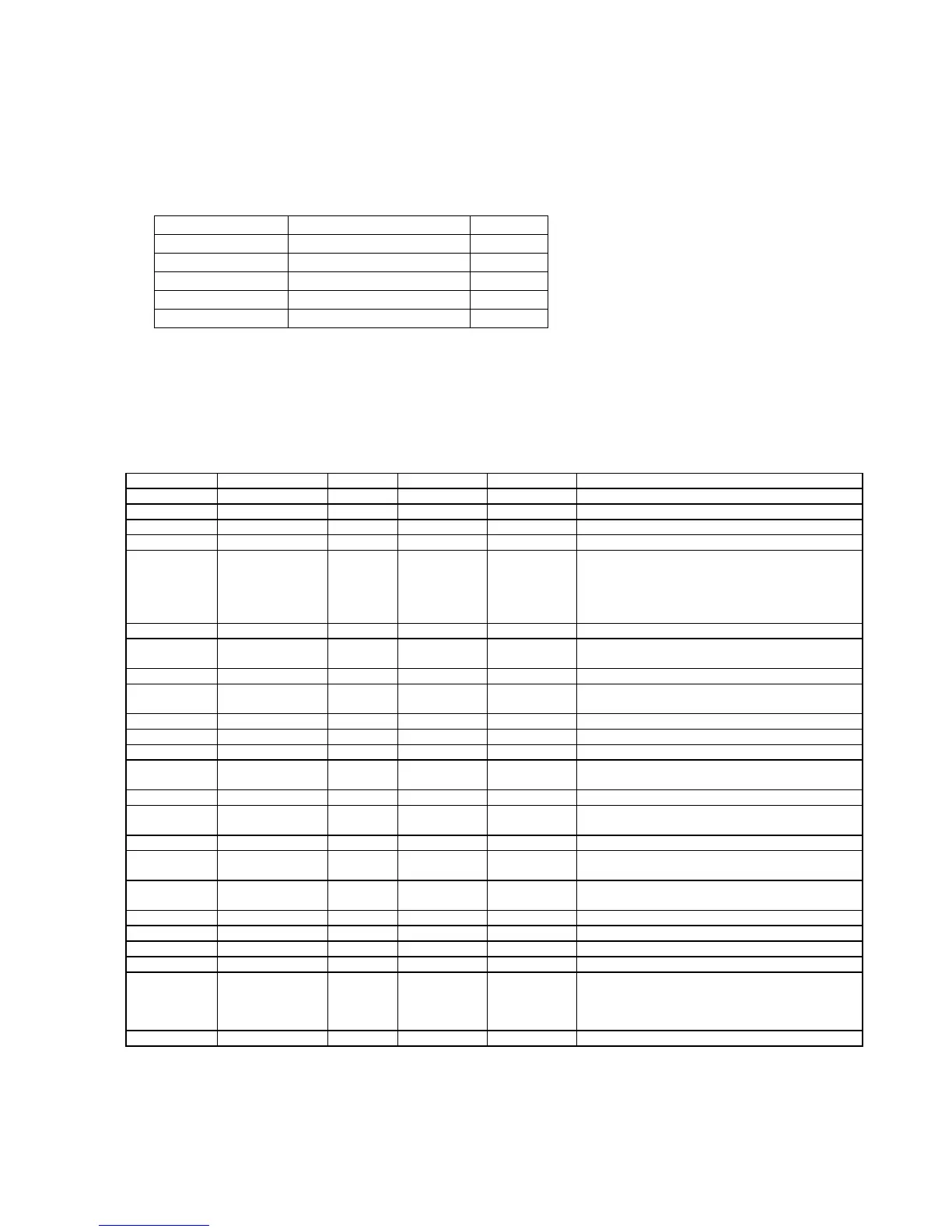

The pump does not send a message except when queried. Each command is characterized by a unique two-

letter command code. Only one command can be issued per line. Case is irrelevant. Command strings sent

by the pump are terminated by the “/” character.

Sets the pump to the RUN state.

Sets the pump to the STOP state.

Sets the flow rate to xx.xxx mL/min

Reads ID of pump where:

x = piston diameter (0=.093, 1=.125, 2=.250)

y = piston stroke (0=.125, 1=.250, 2=.500)

z = pump material (0=ss, 1=pk)

Aaa = EPROM revision

Sets the pump high pressure limit

Sets the pump low pressure limit

Reads the pump high pressure limit

Reads the pump low pressure limit

Sets the pump compressibility compensation

Reads the pump compressibility compensation

Sets the pump refill rate factor (0=Full Out; 1=15:85;

2=30:70; 3=50:50; 4=70:30)

Reads the pump refill rate factor

Disables keypad (default status at power-up is

enabled).

Sets the pump piston diameter (0=.093, 1=.125,

2=.250)

Reads the pump piston diameter (0=.093, 1=.125,

2=.250)

Sets the pump stroke (0=.125, 1=.250, 2=.500)

Reads the pump stroke (0=.125, 1=.250, 2=.500)

Sets the pump material (0=ss, 1=pk)

Reads the pump material (0=ss, 1=pk)

Reads the pump fault status where:

X = motor stall, 0=no fault, 1=fault

Y = hi press limit, 0=no fault, 1=fault

Z = lo press limit, 0=no fault, 1=fault

Sets LED to red and stops pump

Loading...

Loading...