Installation manual

15

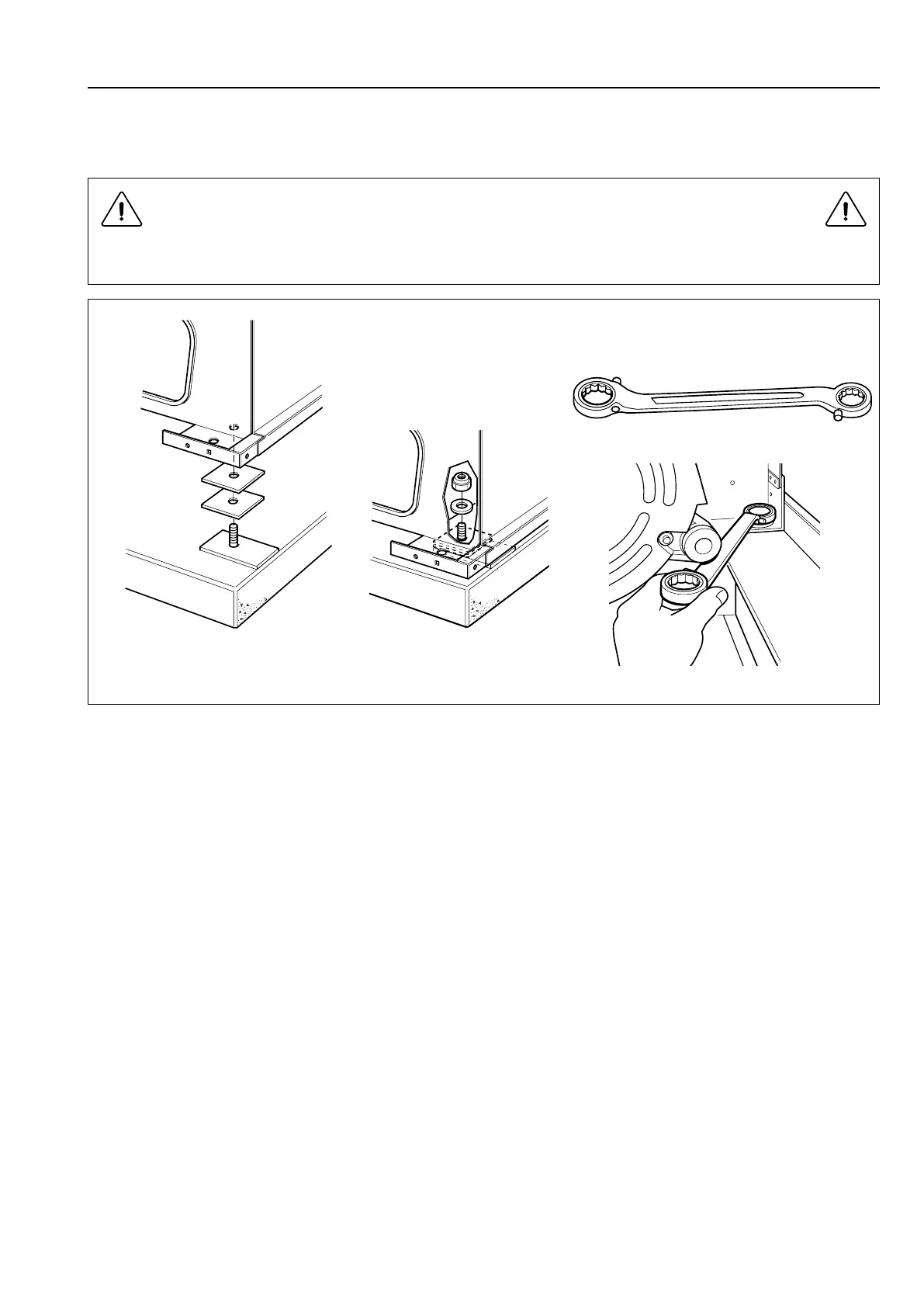

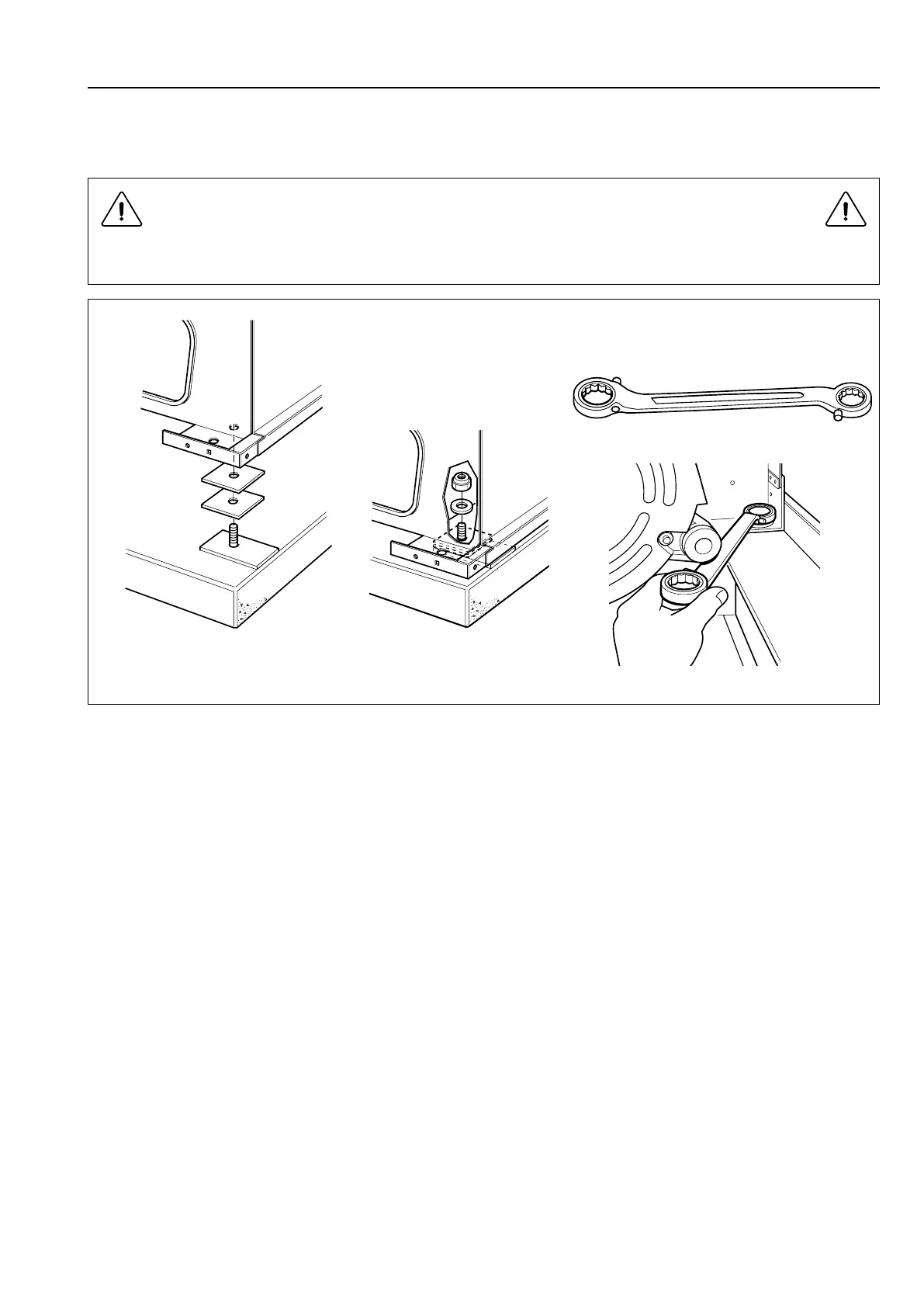

Level the machine by using stainless or galvanized steel washers between the machine and the floor. The washers

must be of a size to cover the support surface. Fit the washers and self-locking nuts supplied with the machine and

tighten well. To tighten the nuts it is recommended to use a rachet wrench, especially in the right rear corner.

It is of the upmost importance that the machine is placed in level, from side to side as well as front to rear. If the

machine is not properly levelled, it may result in out-of-balance without a real out of balance in the drum.

fig.5463A

After the machine has been in use for a while, check and re-tighten the nuts if necessary.

Floor

In this type of machine, the drum is attached directly to the frame. As a result the floor under the machine must be

stable enough to absorb the dynamic forces generated during spin cycles. For that reason, the mounting bolts must

be cast into the floor material itself.

When fixing the machine to an existing cement floor, it must be and at least 150 mm thick. If the floor is less than

150 mm thick, an alternative might be to cast a plinth.

The floor must be able to withstand the loads indicated in the technical data table.

If it isn’t possible to cast the bolts into the floor, an alternative might be to use so-called chemical anchors.

Note!

The use of chemical anchors and/or the use of a fabricated steel mounting base does not reduce the thick-

ness requirement for the underlying concrete floor. The floor MUST be at least 150 mm thick, or a new con-

crete foundation must be poured.

Loading...

Loading...