26

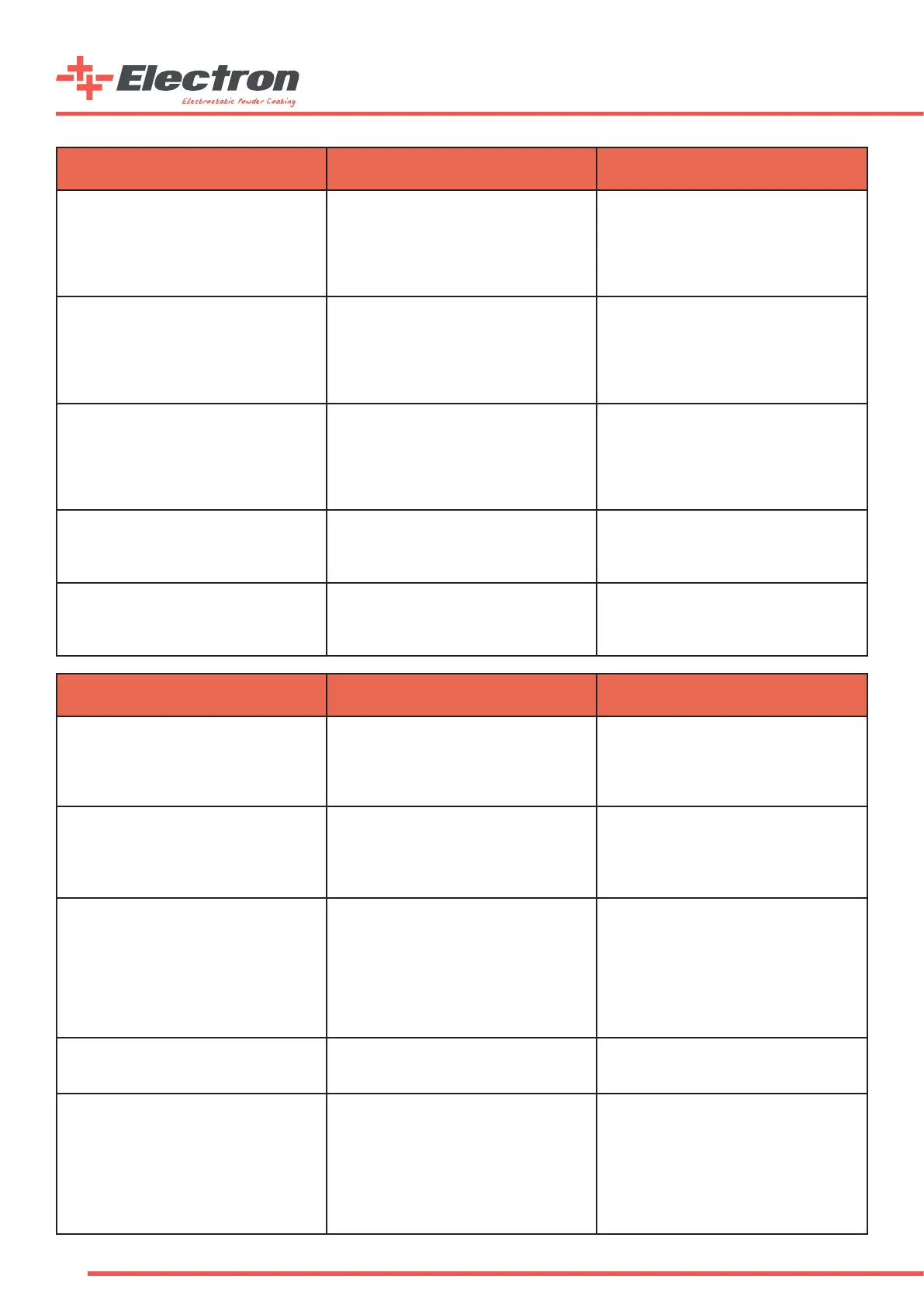

Troubleshoot Code Explanation Suggestions

There isn’t any high voltage and the

control unit is ashing with kV and µA

signs.

1. Gun cable is not connected.

2. The gun cable is connected but not

well xed to the socket

3. Gun cable is damaged.

4. Cascade is damaged.

1. Connect the gun hose.

2. Fix the cable to the socket.

3. Consult an ELECTRON expert.

Powder Paint is being blown from the

gun but the paint doesn’t hold on the

material (No High Voltage Output)

1. The material is not earthed

2. the kV or µA parameter is set to 0

3. The signal from the gun does not

reach to the Cascade.

1. Earth the material or improve the

grounding.

2. Set the kV or µA parameter above 0.

3. Consult an ELECTRON expert.

Powder Paint is being blown from the

gun but the paint doesn’t hold on the

material (No High Voltage Output)

1. Blockage in the powder route

2. The Air or Powder Ratio segment is

set to 0

3. Tearing or disconnection between the

injector and the control unit.

4. If the preferences are adjusted in

a well manner, the proportional valve

inside the gun might be damaged

1. Blockage in the powder route

2. The Air or Powder Ratio segment is

set to 0

3. Tearing or disconnection between the

injector and the control unit.

4. Consult and ELECTRON expert

Pressing the trigger doesn’t start the

control unit (The LED in front of the

control unit is not lit)

1. Gun trigger is damaged 1. Consult and ELECTRON expert

Parameters at the installation are con-

gured but the powder pattern is not

well.

1. Teon bushing in the injector’s life

cycle is ended.

2. Nozzle life cycle is ended.

3. Pneumatic hoses are damaged/broken

or plugged.

4. The air channels are plugged.

5. Injector jet’s life cycle is ended

1. Change the Teon bushing.

2. Change the nozzle

3. Fix the pneumatic hoses or change

them if needed.

4. Clean the injector and the lters.

Change any necessary parts.

5. Change the injector jet.

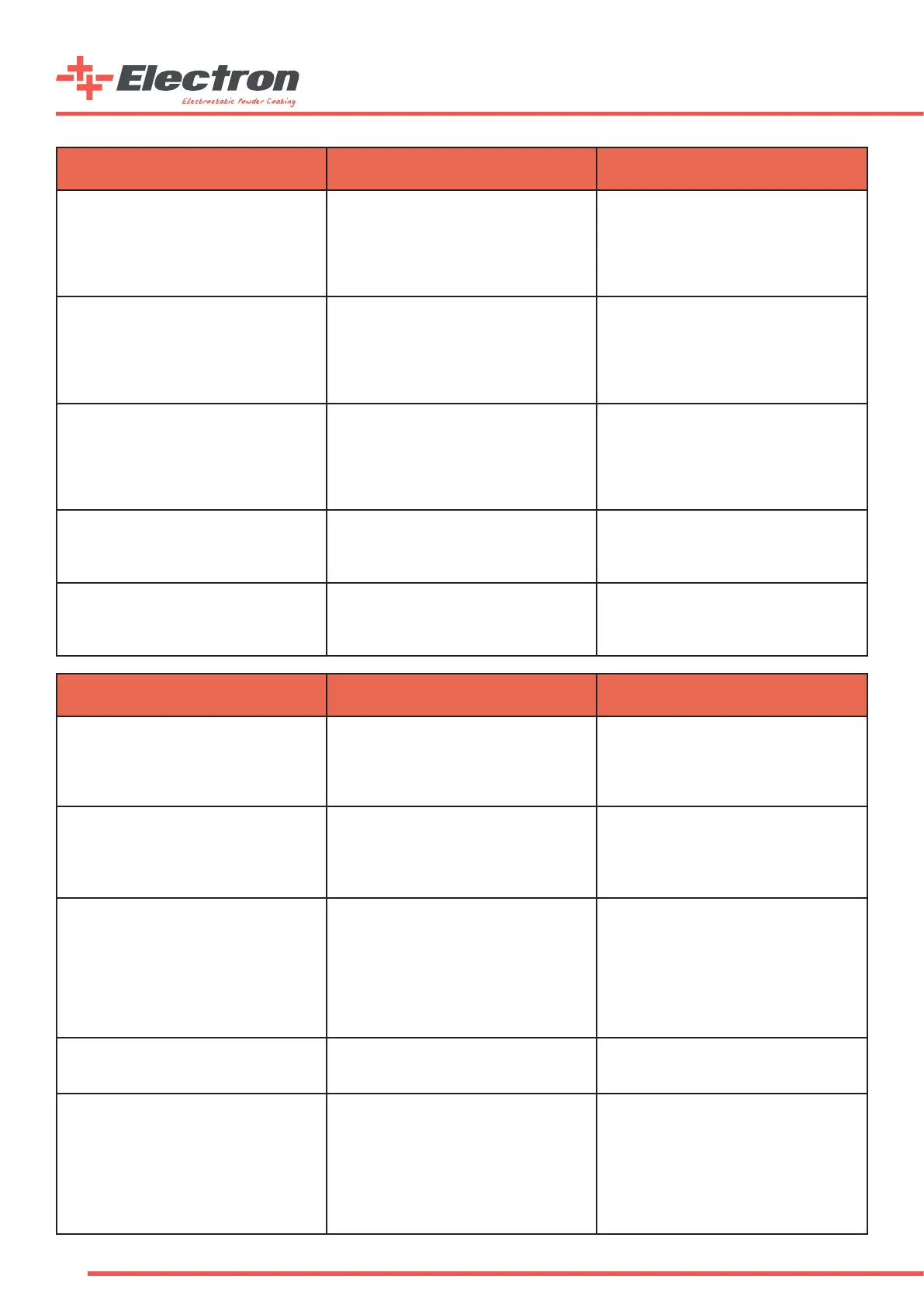

Failure

Possible Failure

Reason

Solution

Powder Paint is being blown from the

gun but the paint doesn’t hold on the

material. (No High Voltage Output)

1. The material is not earthed

2. The kV parameter is set to 0

3. The signal from the gun does not

reach to the Cascade.

1. Earth the material or improve the

grounding.

2. Set the kV parameter above 0

3. Check the connection between the

gun Cascade and the Socket Group for a

possible short circuit inside the gun.

The gun trigger is working and the High

Voltage is working but there is no pow-

der output.

1. Blockage in the powder route

2. Tearing or disconnection between the

injector and the control unit.

1. Remove the blockage in the powder

route.

2. Change the Air or Powder Ratio other

than 0 on the control unit.

3. Remove the blockage or x the dis-

connection.

There isn’t any output High Voltage or

Powder Output.

1. Gun cable is disconnected.

2. Gun cable is damaged

3. Short Circuit or damage in the Gun

Trigger grouping

1. Plug the cable.

2. Check for the damage or change the

cable

3. Check the grouping for short circuit or

damage and change the trigger group if

needed.

The interface buttons are not working as

intended.

1. The Control Unit front panel mem-

brane has a short circuit or damaged.

2. The Control Unit is not correctly

congured.

1. Change the keypad of the membrane.

2. Check the entire conguration of the

Control Unit and redo the conguration

if needed.

The rotary Knob is not changing any

values on the screen.

1. The segment is not chosen.

2. The Knob is damaged.

1. Please select the segment that you

want to change.

2. Change the Rotary Knob.

Loading...

Loading...