EllisSaw.com

8

InIn

11

11

22

//

2 in2 in

11

2 i2 inn

22

//

0

HIGH

SPEED

MID-RANGE

TORQUE

HIGH

TORQUE

MUST RUN MOTOR TO SHIFT TORQUE!

R

e

a

d

a

n

d

u

n

d

e

r

s

t

a

n

d

O

w

n

e

r

s

M

a

n

u

a

l

b

e

f

o

r

e

o

p

e

r

a

t

i

n

g

t

h

i

s

m

a

c

h

i

n

e

!

5050-1

OPERATING INSTRUCTIONS

1. Turn on the drill press and run it at moderate speed.

NOTE: The motor must be moving at a

moderate speed to change the torque range

selection.

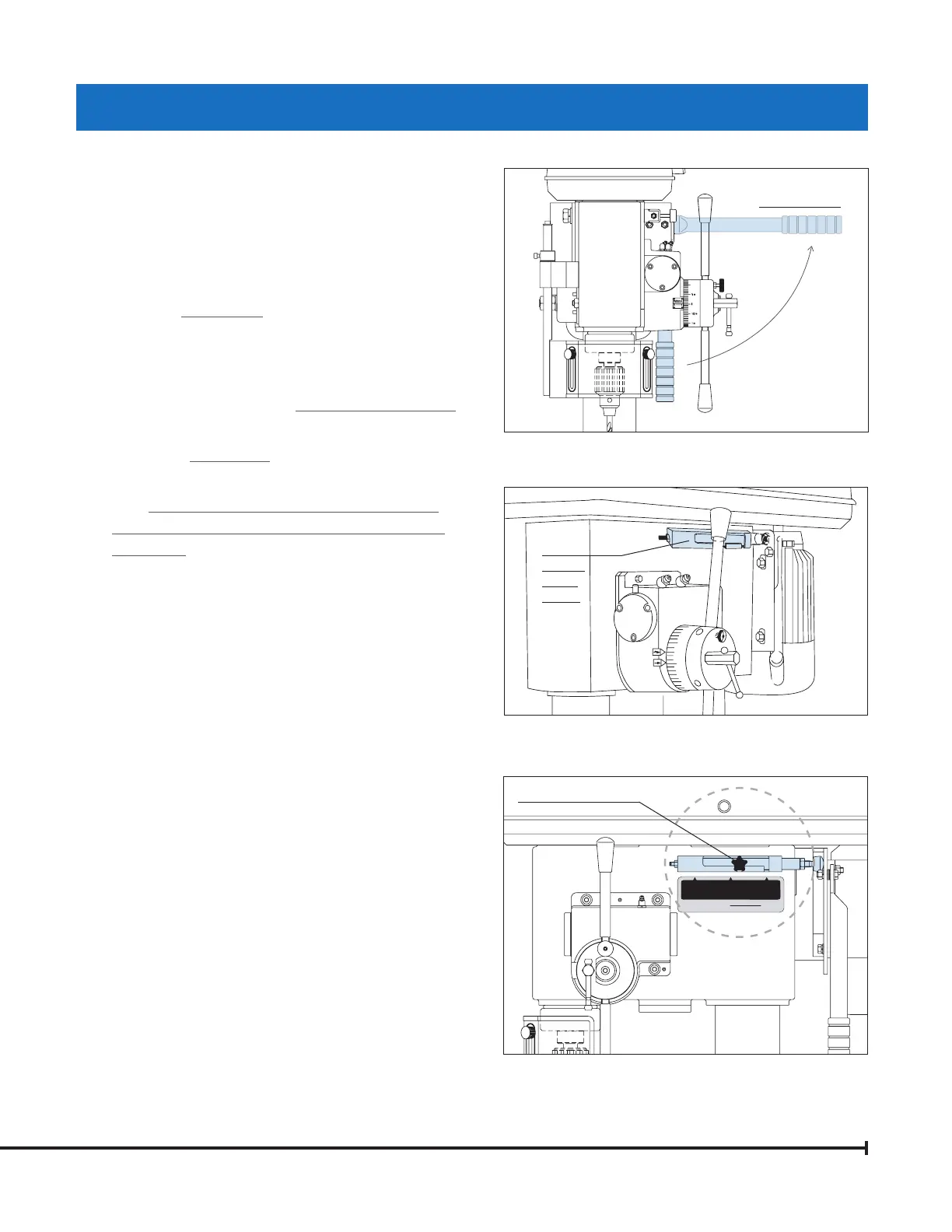

2. Grasp the Shift Handle that is attached to the

Motor Mounting Plate and raise it to a horizontal

position with your right hand. See Figure A.

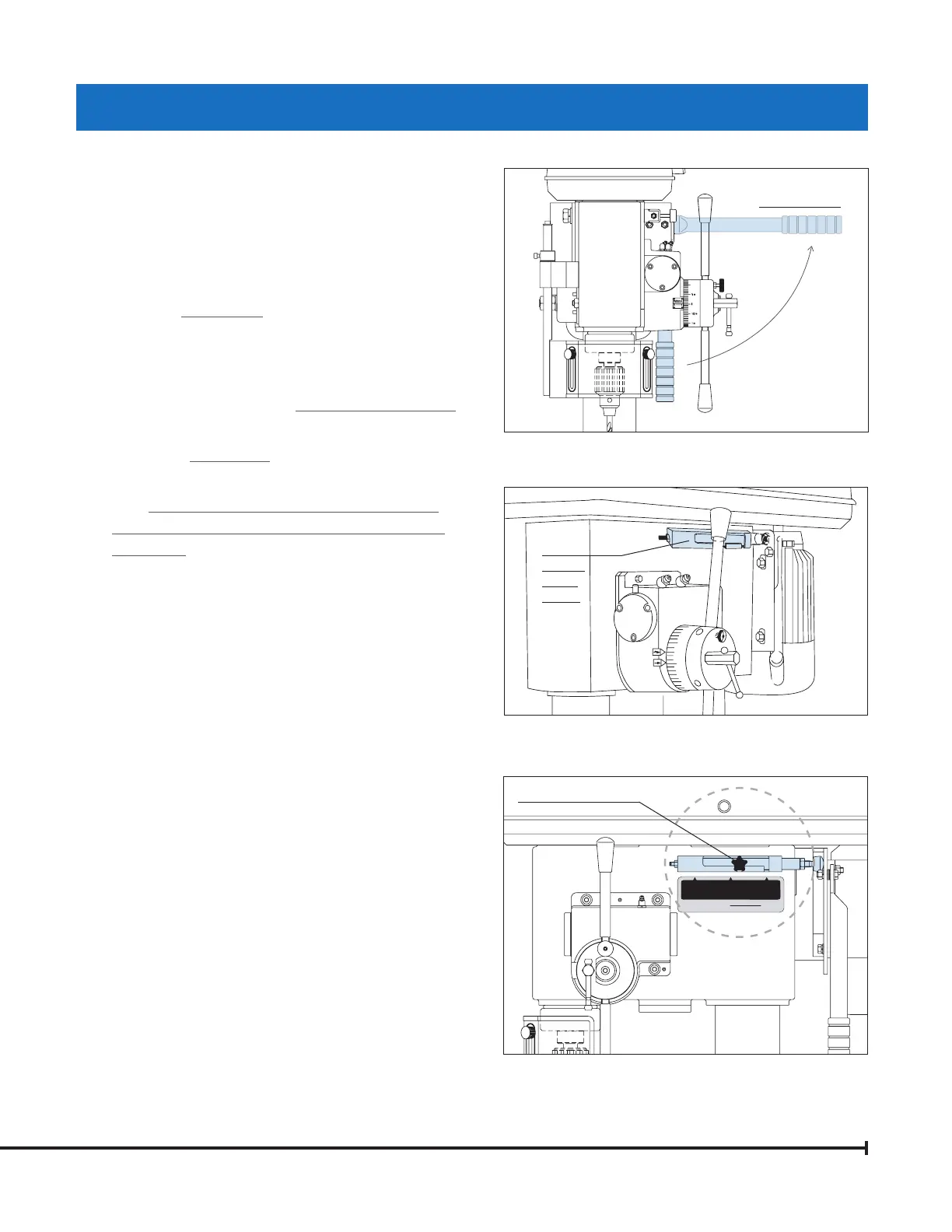

3. Push forward on the Shift Handle just enough to

relieve the pressure on the Torque Bolt Range ASSY.

Refer to Figure B and C.

4. Loosen the Range Knob and raise it out of

the position locking slot. See Figure C.

5. Push the Motor and the Torque Bolt Range ASSY

forward to reduce the spindle speed and increase

the torque. Moving the Torque Bolt Range ASSY and

the motor in the opposite direction will increase the

spindle speed.

NOTE: Make sure that the Range Knob is fully seated

in the locking slot when in the MID-RANGE TORQUE or

HIGH TORQUE positions.

MACHINE SPEED CONTROL

CAPABILITY

NOTE: The complete speed variation from zero to the

maximum of each range is made electronically using the

speed control dial on the Ellis Variable Speed Control

Box (+/- 10%).

•

High Speed, 0 to approximately 1265 RPM range.

This is the range best suited for small drills.

•

Mid-Range Torque, 0 to approximately 930 RPM

speed. This is the general purpose drilling range.

•

High Torque, 0 to approximately 570 RPM. This

range provides the highest torque. Use it for larger

drills and taps and for cutting large holes using

Hole Saws.

Figure C

Figure B

Figure A

TORQUE RANGE OPERATION

Shift Handle

Torque Bolt

Range

ASSY

(p. 9)

Range Knob

Loading...

Loading...