Micro Motion

®

Model D and DT Sensors Instruction Manual 51

Troubleshooting continued

• Use the host controller

If necessary, test the process fluid to confirm the flowmeter

measurement is correct.

Checking for RF or transient-voltage interference

Radio-frequency (RF) or transient-voltage interference can affect the

input or output signals at the transmitter. If you suspect interference, and

can eliminate the source, do so before checking the alternatives

described below.

Output wiring. Output wiring can be affected by interference. Make

sure output wiring from the transmitter is properly grounded in

accordance with the instructions in the transmitter manual. Also make

sure no wires remain exposed at either end of output wiring.

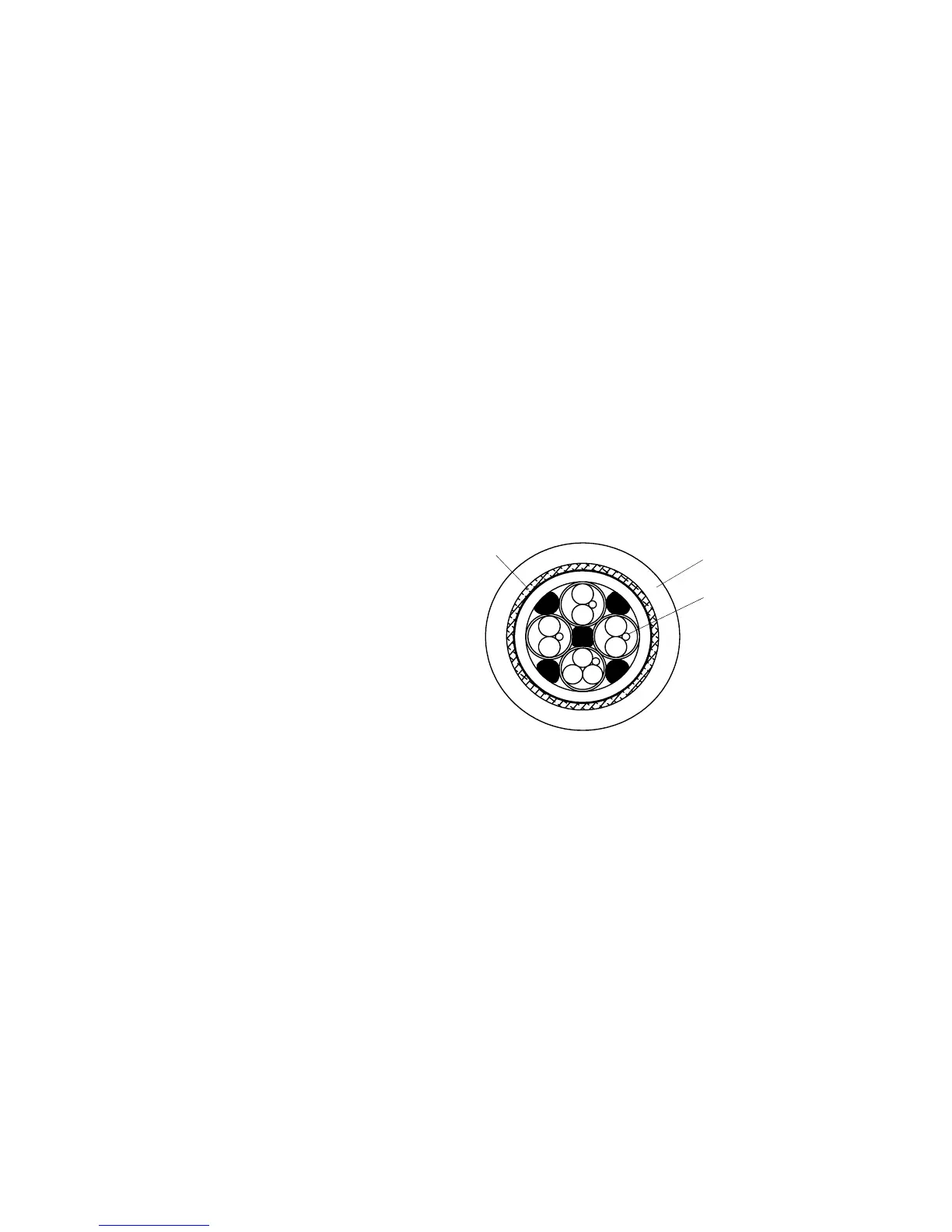

Flowmeter cable. If the flowmeter cable does not have an external

shield (see illustration, below), and is not installed in conduit, it could be

affected by interference. Also make sure no wires remain exposed at

either end of the flowmeter cable.

Cross-section of externally shielded cable

Troubleshooting at the sensor

The tables in the preceding sections refer you to this section for

instructions on troubleshooting at the sensor. To troubleshoot at the

sensor, you might need a digital multimeter (DMM) or similar device. For

some procedures, you might also need the transmitter manual.

Checking flowmeter grounding

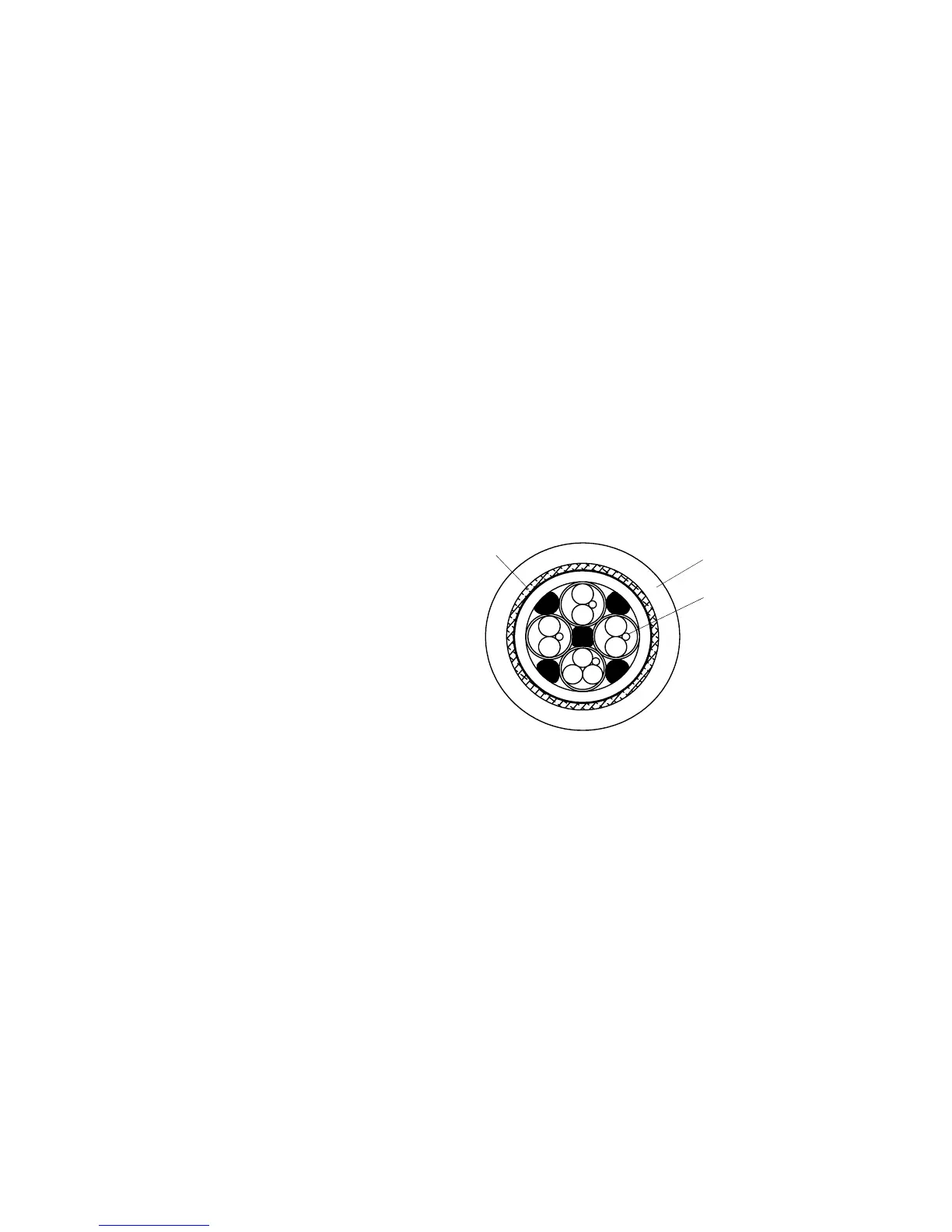

The sensor can be grounded via the piping, as long as joints in the

pipeline are ground-bonded, or by means of a ground screw on the

sensor case. See illustration, below. Transmitter grounding is described

in the transmitter instruction manual.

If the sensor is not grounded via the piping, and if national standards are

not in effect, adhere to these guidelines to ground the sensor via the

junction box:

• Use copper wire, 14 AWG (2,5 mm

2

) or larger wire size for grounding.

• Keep all ground leads as short as possible, less than 1 ohm

impedance.

• Connect ground leads directly to earth, or follow plant standards.

Loading...

Loading...