Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

164 Mentor MP User Guide

www.controltechniques.com Issue: 3

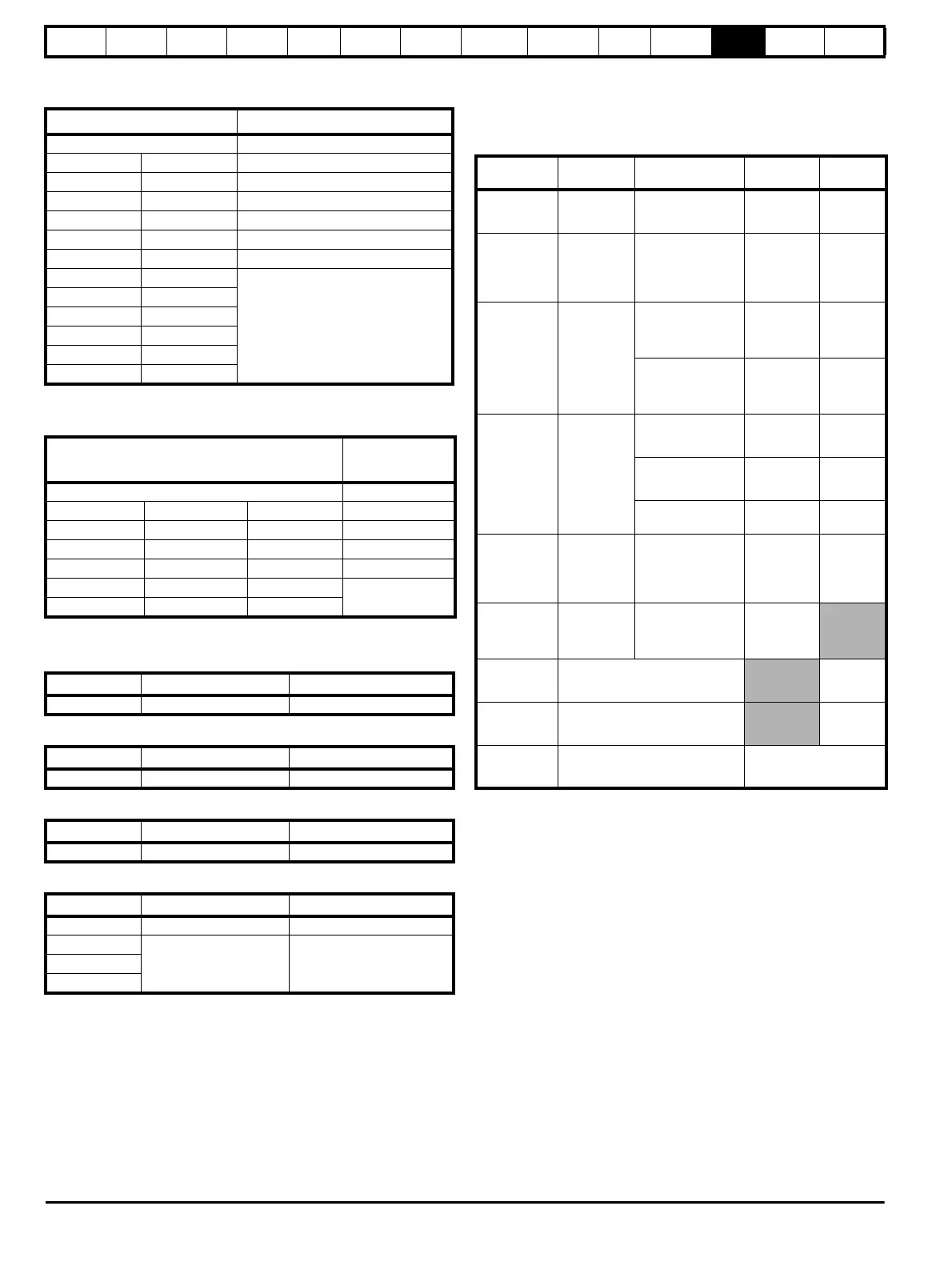

Table 12-37 Mentor MP size 1 drive thyristor I

2

t ratings for

semiconductor fusing

Table 12-38 Mentor MP size 2 drive thyristor I

2

t ratings for

semiconductor fusing

12.2.3 Torque settings

Table 12-39 Drive control, status relay and encoder terminal data

Table 12-40 Drive auxiliary and machine armature terminal data

Table 12-41 Drive power stage terminals

Table 12-42 Drive power stage terminals on size 2 drives

12.2.4 Electromagnetic compatibility (EMC)

This is a summary of the EMC performance of the drive. For full details,

refer to the Mentor MP EMC data sheet which can be obtained from the

supplier of the drive.

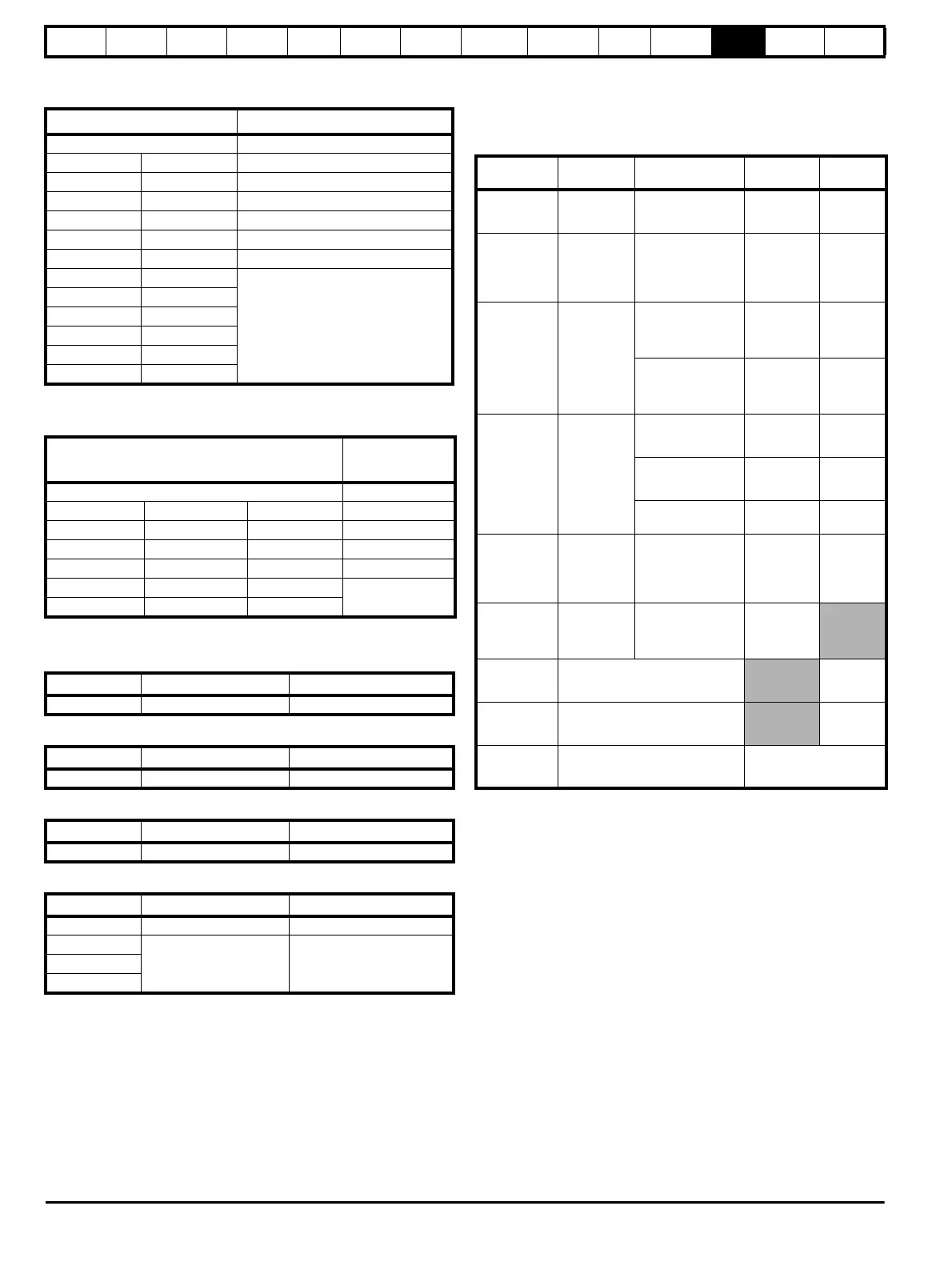

Table 12-43 Immunity compliance

1

See section 4.9.4 Surge immunity of control circuits - long cables and

connections outside a building on page 47 for control ports for possible

requirements regarding grounding and external surge protection.

Model

Thyristor I

2

t (A

2

s)

Auxiliary 400

MP25A4 MP25A5 1030

MP45A4 MP45A5 3600

MP75A4 MP75A5 15000

MP25A4(R) MP25A5(R) 1030

MP45A4(R) MP45A5(R) 3600

MP75A4(R) MP75A5(R) 15000

MP105A4 MP105A5

80000

MP155A4 MP155A5

MP210A4 MP210A5

MP105A4(R) MP105A5(R)

MP155A4(R) MP155A5(R)

MP210A4(R) MP210A5(R)

Model

Thyristor I

2

t

(A

2

s)

Auxiliary 400

MP350A4(R) MP420A4(R) MP550A4(R) 320000

MP350A6(R) MP470A5(R) MP470A6(R) 281000

MP700A4(R) MP825A4(R) MP900A4(R) 1050000

MP700A6(R) MP825A5(R) MP825A6(R) 1200000

MP1200A4(R) MP1200A5(R) MP1200A6(R)

2720000

MP1850A4(R) MP1850A5(R) MP1850A6(R)

Model Connection type Torque setting

All Plug-in terminal block 0.5 Nm 0.4 lb ft

Model Connection type Torque setting

All Terminal block 0.5 Nm 0.4 lb ft

Model Connection type Torque setting

All M8 stud 10 Nm 7.4 lb ft

Model Connection type Torque setting

Size 2A M10 stud 15 Nm (11.06 lb ft)

Size 2B

M12 stud 30 Nm (22.12 Ib ft)Size 2C

Size 2D

Standard

Type of

immunity

Test specification Application Level

IEC 61000-4-2

EN 61000-4-2

Electrostatic

discharge

6kV contact

discharge

8kV air discharge

Module

enclosure

Level 3

(industrial)

IEC 61000-4-3

EN 61000-4-3

Radio

frequency

radiated field

10V/m prior to

modulation

80 - 1000MHz

80% AM (1kHz)

modulation

Module

enclosure

Level 3

(industrial)

IEC 61000-4-4

EN 61000-4-4

Fast transient

burst

5/50ns 2kV transient

at 5kHz repetition

frequency via

coupling clamp

Control lines

Level 4

(industrial

harsh)

5/50ns 2kV transient

at 5kHz repetition

frequency by direct

injection

Power lines

Level 3

(industrial)

IEC 61000-4-5

EN 61000-4-5

Surges

Common mode 4kV

1.2/50μs waveshape

AC supply

lines:

line to ground

Level 4

Differential mode 2kV

1.2/50μs waveshape

AC supply

lines:

line to line

Level 3

Lines to ground

Signal ports to

ground

1

Level 2

IEC 61000-4-6

EN 61000-4-6

Conducted

radio

frequency

10V prior to

modulation

0.15 - 80MHz

80% AM (1kHz)

modulation

Control and

power lines

Level 3

(industrial)

IEC 61000-4-11

EN 61000-4-11

Voltage dips

and

interruptions

-30% 10ms

+60% 100ms

-60% 1s

<-95% 5s

AC power

ports

EN 50082-1

IEC 61000-6-1

EN 61000-6-1

Generic immunity standard for the

residential, commercial and light -

industrial environment

Complies

EN 50082-2

IEC 61000-6-2

EN 61000-6-2

Generic immunity standard for the

industrial environment

Complies

EN 61800-3

IEC 61800-3

EN 61800-3

Product standard for adjustable

speed power drive systems

(immunity requirements)

Meets immunity

requirements for first and

second environments

Loading...

Loading...