Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

54 Mentor MP User Guide

www.controltechniques.com Issue: 3

Feedback device connections

Ab, Fd, Fr encoders

4.15 Connecting an encoder

Additional measures to prevent unwanted emission of radio frequency

noise are only required where the installation is subject to specific

requirements for radio frequency emission.

Encoder connections:

To ensure suppression of radio frequency emission, observe the

following:

• Use an encoder with the correct impedance

• Use a cable with individually shielded twisted pairs.

• Connect the cable shields to 0V at both the drive and the encoder,

using the shortest possible links (pig-tails).

• The cable should not be interrupted. If interruptions are unavoidable,

ensure the absolute minimum length of "pig-tail" in the shield

connections at each interruption. Use a connection method that

provides substantial metallic clamps for the cable shield

terminations.

The above applies where the encoder body is isolated from the motor

and where the encoder circuit is isolated from the encoder body. Where

there is no isolation between the encoder circuits and motor body, and in

case of doubt, the following additional requirements must be observed to

give the best possible noise immunity.

• The shields must be directly clamped to the encoder and to the

drives grounding bracket. This may be achieved by clamping of the

individual shields or by providing an additional overall shield that is

clamped.

The recommendations of the encoder manufacturer should also be

adhered to for the encoder connections.

N

In order to guarantee maximum noise immunity for any application

double shielded cable as shown should be used.

In some cases single shielding of each pair of differential signals cables,

or a single overall shield with individual shield on the thermistor

connections is sufficient. In these cases all the shields should be

connected to ground and 0V at both ends.

If the 0V is required to be left floating a cable with individual shields and

an overall shield must be used.

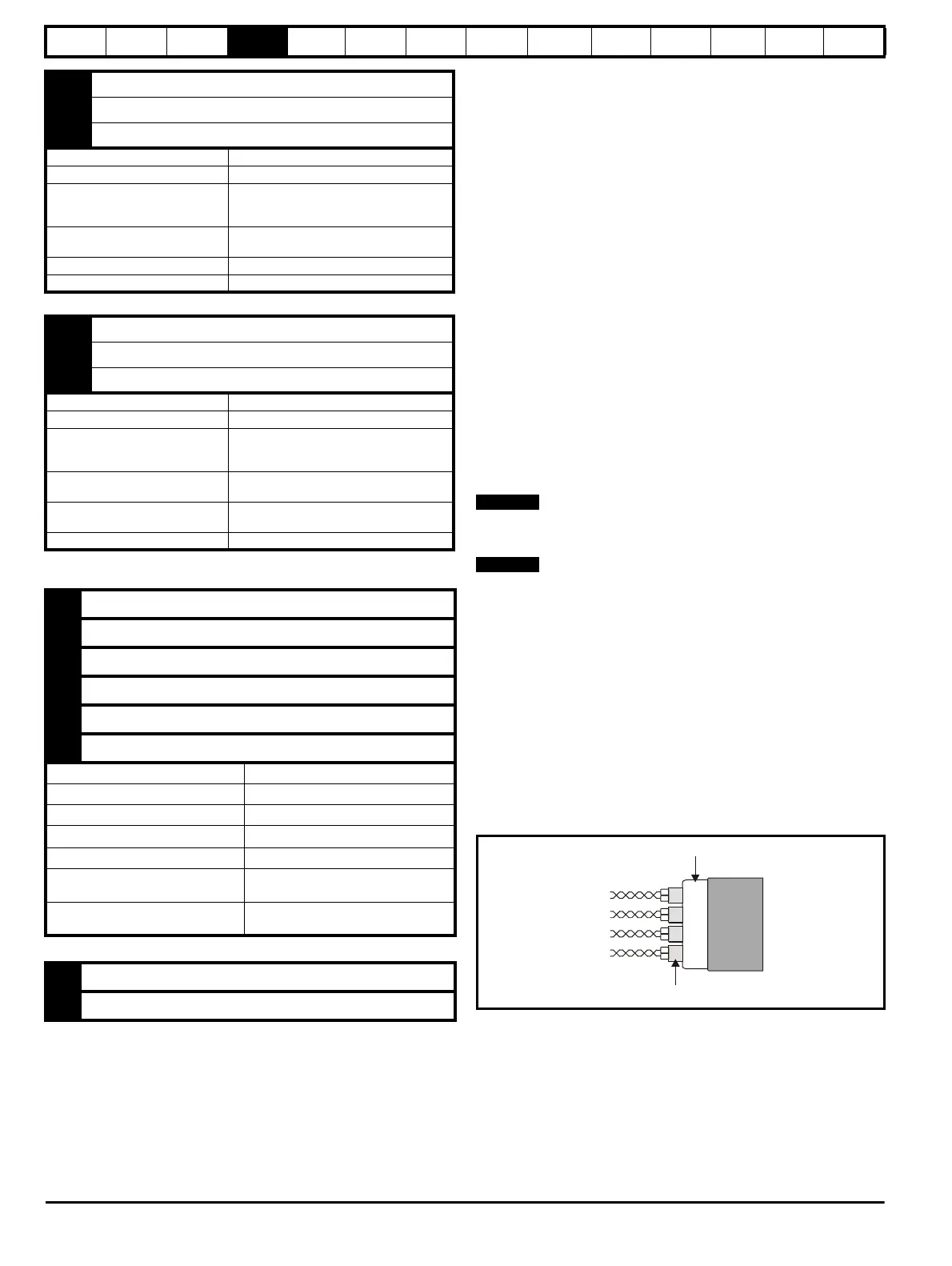

Figure 4-21 and Figure 4-22 illustrate the preferred construction of cable

and the method of clamping. The outer sheath of the cable should be

stripped back enough to allow the clamp to be installed. The shield must

not be broken or opened at this point. The clamps should be installed

close to the drive or feedback device, with the ground connections made

to a ground plate or similar metallic ground surface.

Figure 4-21 Feedback cable, twisted pair

51 Relay 1 common

52 Relay 1 normally closed

53 Relay 1 normally open

Default function Drive OK indicator

Contact voltage rating 240Vac, installation over-voltage category II

Contact maximum current rating

5A AC 240V

5A DC 30V resistive load

0.5A DC 30V inductive load (L/R = 40ms)

Contact minimum recommended

rating

12V, 100mA

Default contact position Closed when power on and drive OK

Sampling period 4ms

61 Relay 2 common

62 Relay 2 normally closed

63 Relay 2 normally open

Default function Contactor enable

Contact voltage rating 240Vac, installation over-voltage category II

Contact maximum current rating

5A AC 240V

5A DC 30V resistive load

0.5A DC 30V inductive load (L/R = 40ms)

Contact minimum recommended

rating

12V, 100mA

Default contact position

Closed when AC or DC contactor is

required to be closed.

Sampling period 4ms

A Channel A, Frequency or Forward inputs

A\ Channel A\, Frequency\ or Forward\ inputs

B Channel B, Direction or Reverse inputs

B\ Channel B\, Direction\ or Reverse\ inputs

Z Marker pulse channel Z

Z\ Marker pulse channel Z\

Type EIA 485 differential receivers

Maximum input frequency 500kHz

Line loading <2 unit loads

Line termination components

100

Ω for 2 - 5V range (switchable)

Working common mode range +12V to –7V

Absolute maximum applied voltage

relative to 0V

±25V

Absolute maximum applied differential

voltage

±25V

+ + supply

0V 0V

Twisted

pair

cable

Twisted pair shield

Cable

Cable overall shield

Loading...

Loading...