Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

50 Mentor MP User Guide

www.controltechniques.com Issue: 3

Table 4-24 Fan supply specification

Cabling should be 300V rated. Rated for at least 3A continuous in line

with local wiring regulations. Cabling should be protected 3A non time

delay fuses i.e. gG, Class CC or Class J and rated for at least 300V, in

accordance with local wiring regulations.

4.13 Control connections

Refer to Figure 4-20 to understand the connection of the different power

connections.

4.13.1 General

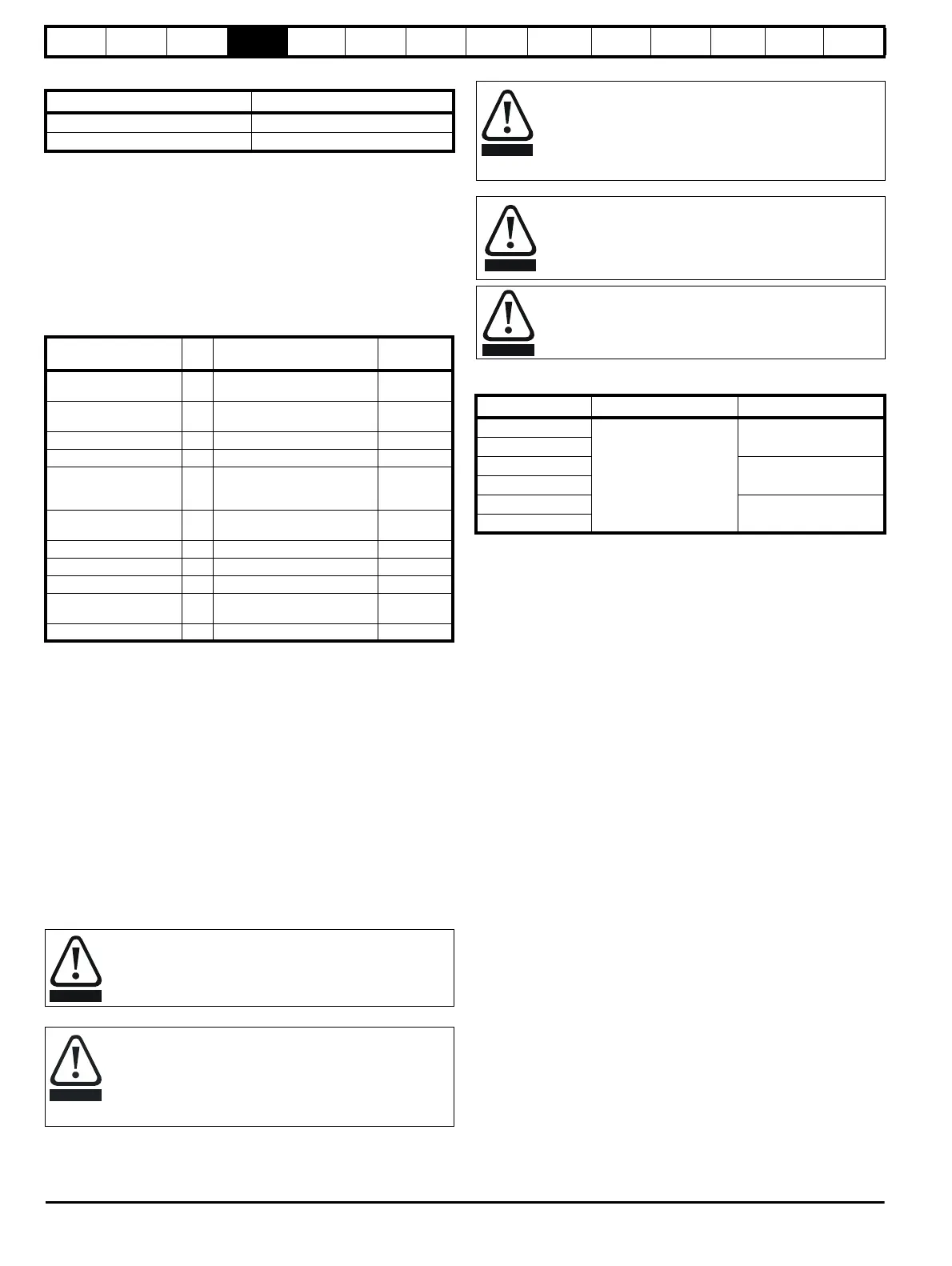

Table 4-25 The control connections consist of:

Key:

All analog terminal functions can be programmed in menu 7.

All digital terminal functions (including the relays) can be programmed in

menu 8.

The setting of Pr 6.04 can cause the function of digital inputs T25 to T27

to change. For more information, refer to section 11.22.5 Start / stop

logic modes on page 143.

Table 4-26 Control connection recommended cable sizes

Fan configuration Supply specification

230V 230V ±10%

115V 115V ±10%

Function Qty Control parameters available

Terminal

number

Differential analog input 1

Destination, offset, invert,

scaling

5,6

Single ended analog

input

2

Mode, offset, scaling, invert,

destination

7,8

Analog output 2 Source, mode, scaling, 9,10

Digital input 3 Destination, invert, logic select 27, 28, 29

Digital input / output 3

Input / output mode select,

destination / source, invert,

logic select

24, 25, 26

Relay 2 Source, invert

51, 52, 53

61, 62, 63

Drive enable 1 Logic select 31

+10V User output 1 4

+24V User output 1 22

0V common 6

1, 3, 11, 21,

23, 30

+24V External input 1 2

Destination

parameter:

Indicates the parameter which is being controlled by the

terminal / function

Source

parameter:

Indicates the parameter being output by the terminal

Mode

parameter:

Analog - indicates the mode of operation of the terminal,

i.e. voltage 0-10V, current 4-20mA etc.

Digital - indicates the mode of operation of the terminal,

i.e. positive / negative logic, open collector.

If the control circuits are to be connected to other circuits

classified as Safety Extra Low Voltage (SELV) (e.g. to a

personal computer), an additional isolating barrier must be

included in order to maintain the SELV classification.

If any of the digital inputs (including the drive enable input)

are connected in parallel with an inductive load (i.e.

contactor or motor brake) then suitable suppression (i.e.

diode or varistor) should be used on the coil of the load. If no

suppression is used then over voltage spikes can cause

damage to the digital inputs on the drive.

The control circuits are isolated from the power circuits in the

drive by basic insulation (single insulation) only. The installer

must ensure that the external control circuits are insulated

from human contact by at least one layer of insulation

(supplementary insulation) rated for use at the AC supply

voltage.

Status relay contacts are over-voltage category II.

A fuse or other over-current protection should be installed to

the relay circuit.

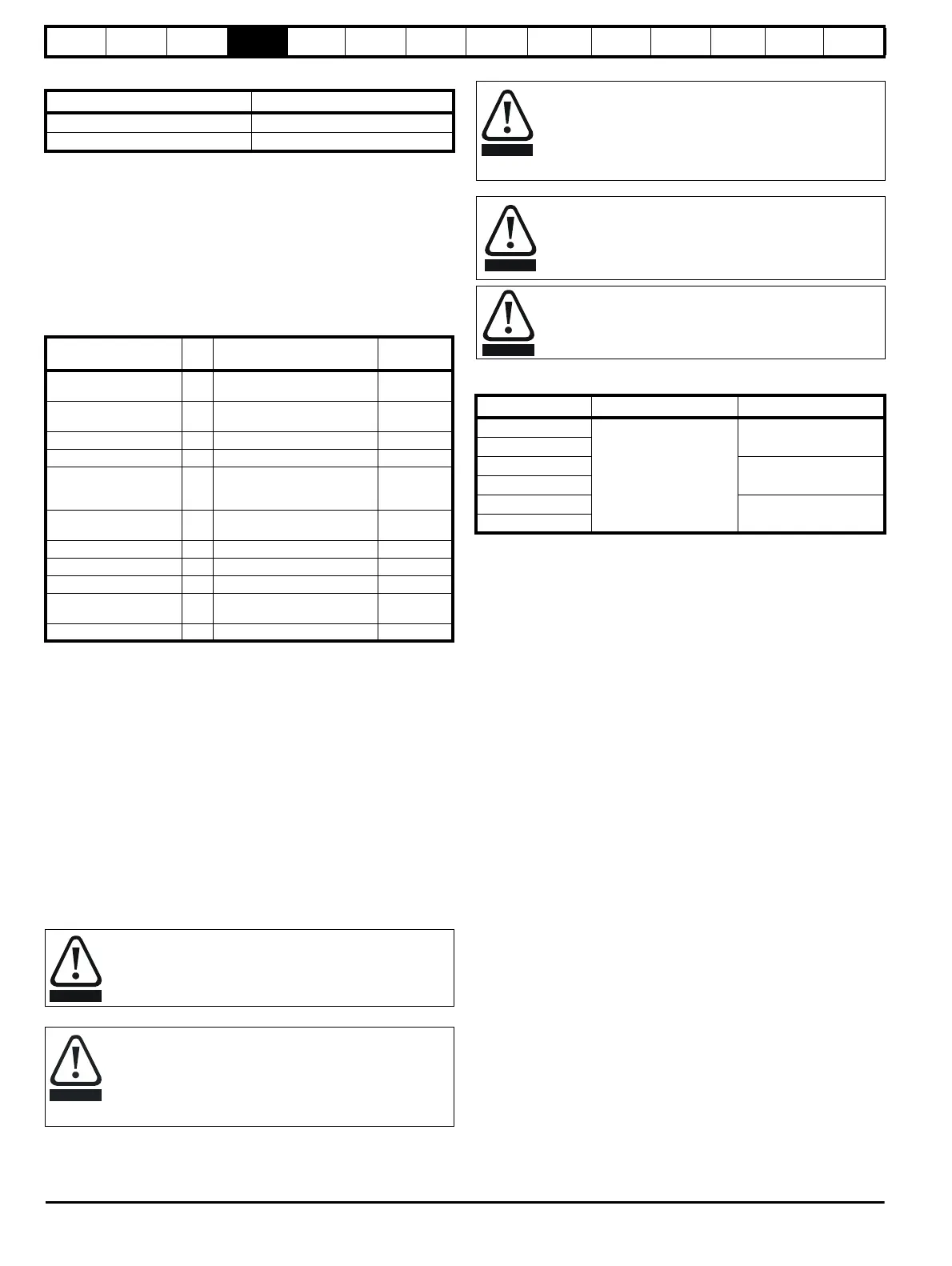

Terminal Minimum cable size Maximum cable size

Machine armature

0.5mm

2

20 AWG

5mm

2

10 AWG

Auxiliary

Control I/O

1.31mm

2

16 AWG

Encoder

Tachogenerator

2.5mm

2

12 AWG

Status relays

Loading...

Loading...