Mounting Deltabar PMD78B HART

10 Endress+Hauser

5.1.4 Installing pressure piping

• For recommendations for routing pressure piping, refer to DIN 19210 "Differential pressure

piping for flow measurement devices" or the corresponding national or international

standards

• When routing the pressure piping outdoors, ensure sufficient anti-freeze protection, e.g. by

using pipe heat tracing

• Install the pressure piping with a monotonic gradient of at least 10%

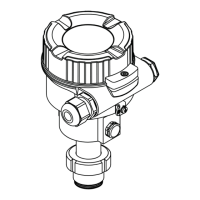

5.2 Mounting the device

5.2.1 Level measurement

Level measurement in an open vessel, diaphragm seal on one side with temperature

isolator

• Mount the device directly on the vessel

• The negative side is open to atmospheric pressure

Level measurement in a closed vessel, diaphragm seal on one side with temperature

isolator

• Mount the device directly on the vessel

• Always connect the piping on the negative side above the maximum level

Level measurement in a closed vessel, diaphragm seal on one side or both sides with

capillary

Mount the device below the lower diaphragm seal

Level measurement is only guaranteed between the upper edge of the lower diaphragm seal

and the lower edge of the upper diaphragm seal.

Level measurement in a closed vessel with superimposed vapor, diaphragm seal on one

side with temperature isolator

• Mount the device directly on the vessel

• Always connect the piping on the negative side above the maximum level

• The condensate trap ensures constant pressure on the negative side

• When measuring in media with solid parts (such as dirty liquids) installing separators and

drain valves is useful for capturing and removing sediment

5.2.2 Differential pressure measurement

Differential pressure measurement in gases, vapors and liquids, diaphragm seal on one

side or two sides with capillary

• Mount diaphragm seals with capillaries on pipes at the top or side

• In vacuum applications, mount the device below the measuring point

Loading...

Loading...