What to do if Endress+Hauser Measuring Instruments device does not respond?

- JJacqueline RuizAug 16, 2025

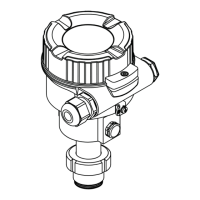

If your Endress+Hauser Measuring Instruments device does not respond, ensure the supply voltage matches the nameplate specification, correct the polarity if it's wrong, verify the cables are properly connected to the terminals, and increase the supply voltage if the load resistance is too high to reach the minimum terminal voltage.