Mounting Deltabar PMD78B HART

8 Endress+Hauser

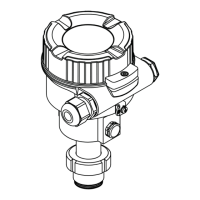

Always firmly tighten the housing cover and the cable entries.

1. Counter-tighten the cable entries.

2. Tighten the coupling nut.

5.1.2 Installation instructions

• To ensure optimal readability of the local display, adjust the housing and local display

• Endress+Hauser offers a mounting bracket to mount the device on pipes or walls

• Use flushing rings for flanges, flange seals and pancake seals if buildup or clogging can be

expected at the membrane

• The flushing ring is clamped between the process connection and the flange, flange seal

or pancake seal

• Material buildup in front of the membrane is flushed away, and the pressure chamber is

vented, via the two lateral flushing holes

• When measuring in media containing solids (e.g. dirty liquids), installing separators and

drain valves is useful for capturing and removing sediment

• Using a valve manifold allows for easy commissioning, installation and maintenance

without interrupting the process

• When mounting the device, establishing the electrical connection and during operation:

prevent the penetration of moisture into the housing

• Point the cable and plug downwards as much as possible to prevent moisture from entering

(e.g. rainwater or condensation)

5.1.3 Installation instructions for devices with diaphragm seals

NOTICE

Improper handling!

Damage to the device!

‣

The diaphragm seal and pressure transmitter form a closed, calibrated system which has

been filled with diaphragm seal fill fluid. Never open any of the holes for fill fluid.

‣

Ensure strain relief to prevent the capillary from bending (bending radius ≥

100 mm (3.94 in)).

‣

Do not use capillaries as a carrying aid for the diaphragm seals.

‣

Observe the application limits of the fill fluid.

General information

In the case of devices with diaphragm seals and capillaries, the zero point shift caused by the

hydrostatic pressure of the filling liquid column in the capillaries must be taken into account

when selecting the measuring cell. Perform zero adjustment if necessary. If a measuring cell

with a small measuring range is selected, a position adjustment can cause the measuring cell

to go over range (position adjustment due to zero point offset, caused by the orientation of

the fill fluid liquid column).

For devices with a capillary, use a suitable bracket (mounting bracket) for mounting.

When mounting, sufficient strain relief must be provided for the capillary to prevent the

capillary from bending (capillary bending radius ≥ 100 mm (3.94 in)).

Mount the capillary so that it is vibration-free (in order to avoid additional pressure

fluctuations).

Loading...

Loading...