Liquiphant FTL31

4 Endress+Hauser

Function and system design

Measuring principle

A piezoelectric drive causes the tuning fork of the Liquiphant FTL31 to vibrate at its resonance

frequency. When the tuning fork is immersed in a liquid, its intrinsic frequency changes due to the

change in density of the surrounding medium. The electronics system in the point level switch

monitors the resonance frequency and indicates whether the tuning fork is vibrating in air or is

covered by liquid.

A signal is output via the DC-PNP or AC/DC electrical connection.

Measuring system

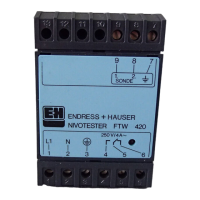

The measuring system consists of a Liquiphant FTL31 point level switch, e.g. for connection to

programmable logic controllers (PLC), a mini-contactor or solenoid valve.

A0020911

1 Overfill prevention or upper level detection MAX (maximum safety)

2 Lower level detection MIN (minimum safety)

3 Lower level detection MIN, e.g. dry running protection for pump

Loading...

Loading...