Liquipoint T FTW 31, FTW 32

Endress + Hauser 3

Function and system design

Measuring principle An alternating voltage exists between the rod probes in an empty tank.

As soon as the conductive liquid in the tank creates a connection between the ground probe rod

and, for example, the maximum probe rod, a measurable current flows and the Liquipoint T

switches. With level limit detection, the Liquipoint T switches back as soon as the liquid clears the

maximum probe. With two-point control, the Liquipoint T does not switch back until the MAX and

MIN probe is cleared.

Using alternating voltage prevents corrosion of the probe rods and electrolytic destruction of the

product. The material used for the tank walls is not important for measurement because the

system is designed as a closed potential-free circuit between the probe rods and the electronics.

There is absolutely no danger if the probe rods are touched during operation.

Measuring system Probes with integrated electronic insert (compact-instrument version)

The measuring system consists of:

•

FTW 31, FTW 32 with two/three rods or ropes and an electronic insert

•

Control units, switches or signal transmitters, e.g. process control systems PLC, relays, etc.

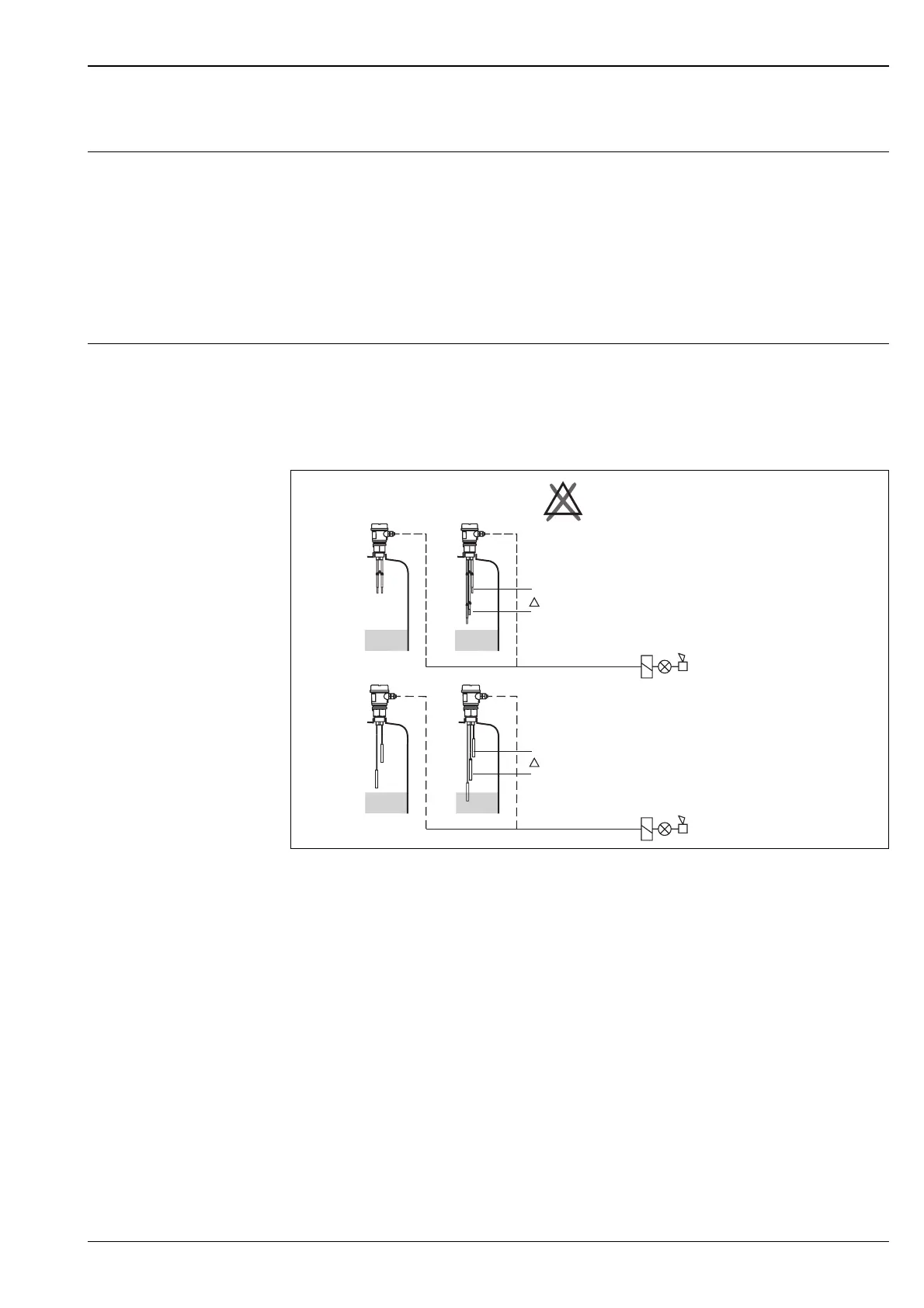

L00-FTW3xxxx-14-05-xx-en-001

Independent of the tank material

!

Note!

The compact-instrument version with three probes or rods is always used in ∆s mode.

E

X

FTW 32

FTW 31

s

s

1 - 2 points

2 - 3 ropes

1 - 2 points

2 - 3 rods

Loading...

Loading...