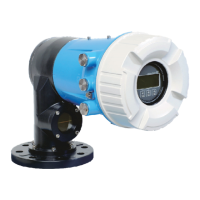

Proservo NMS80/81/83

Endress+Hauser 17

Further parameter settings

The following parameters affect the safety function. However, they may be freely configured in

accordance with the application:

It is recommended to note down the configured values!

Parameter Parameter name

Setup Upper density

Setup Process condition

Setup High stop level

Setup Low stop level

Setup Empty

Current input measurement: Setup → Advanced setup → Input/output → Analog I/O

0 % value

100 % value

The following parameters affect the safety function and are not freely configurable in Expert mode.

Instead, they are automatically set by the device to the safety-related values mentioned at the start

of SIL confirmation:

Parameter Preset value

Operation → Gauge command → Gauge command Level

Setup → Advanced setup → Input/output → Digital input mapping → Digital input

source 1

None

Setup → Advanced setup → Input/output → Digital input mapping → Digital input

source 2

None

Setup → Advanced setup → Input/output → Digital Xy-z → Contact type Normally closed

Setup → Advanced setup → Input/output → Digital Xy-z → Output simulation Disable

Setup → Advanced setup → Application → Tank calculation → HyTD → HyTD mode No

Setup → Advanced setup → Application → Tank calculation → CTSh → CTSh mode No

Setup → Advanced setup → Application → Alarm → Alarm X → Error value All alarms

Setup → Advanced setup → Application → Alarm → Alarm X → Alarm mode On

Setup → Advanced setup → Safety settings → Output out of range Alarm

Diagnostics → Simulation → Simulation distance on Off

Diagnostics → Simulation → Current output 1 simulation Off

Expert → Input/output → Digital Xy-z → Error on event Any error

Expert → Input/output → Analog I/O → Error on event Any error

Expert → Input/output → Analog I/O → Output out of range Alarm

Expert → Input/output → Analog I/O → Feedback threshold 1 s

Those parameters which are not mentioned do not affect the safety function and can be

configured to any meaningful values. The visibility of the parameters mentioned in the

operating menu depends in part on the user role, the SW options ordered and on the

configuration of other parameters.

Unlocking a SIL device

When SIL locking is active on a device, the device is protected against unauthorized operation by

means of a locking code and, as an additional option, by means of a hardware write protection

switch. The device must be unlocked in order to change the configuration for proof-tests as per test

sequence A → 20, test sequence B → 22or test sequence C → 24.

Loading...

Loading...