Proservo NMS80/81/83

Endress+Hauser 31

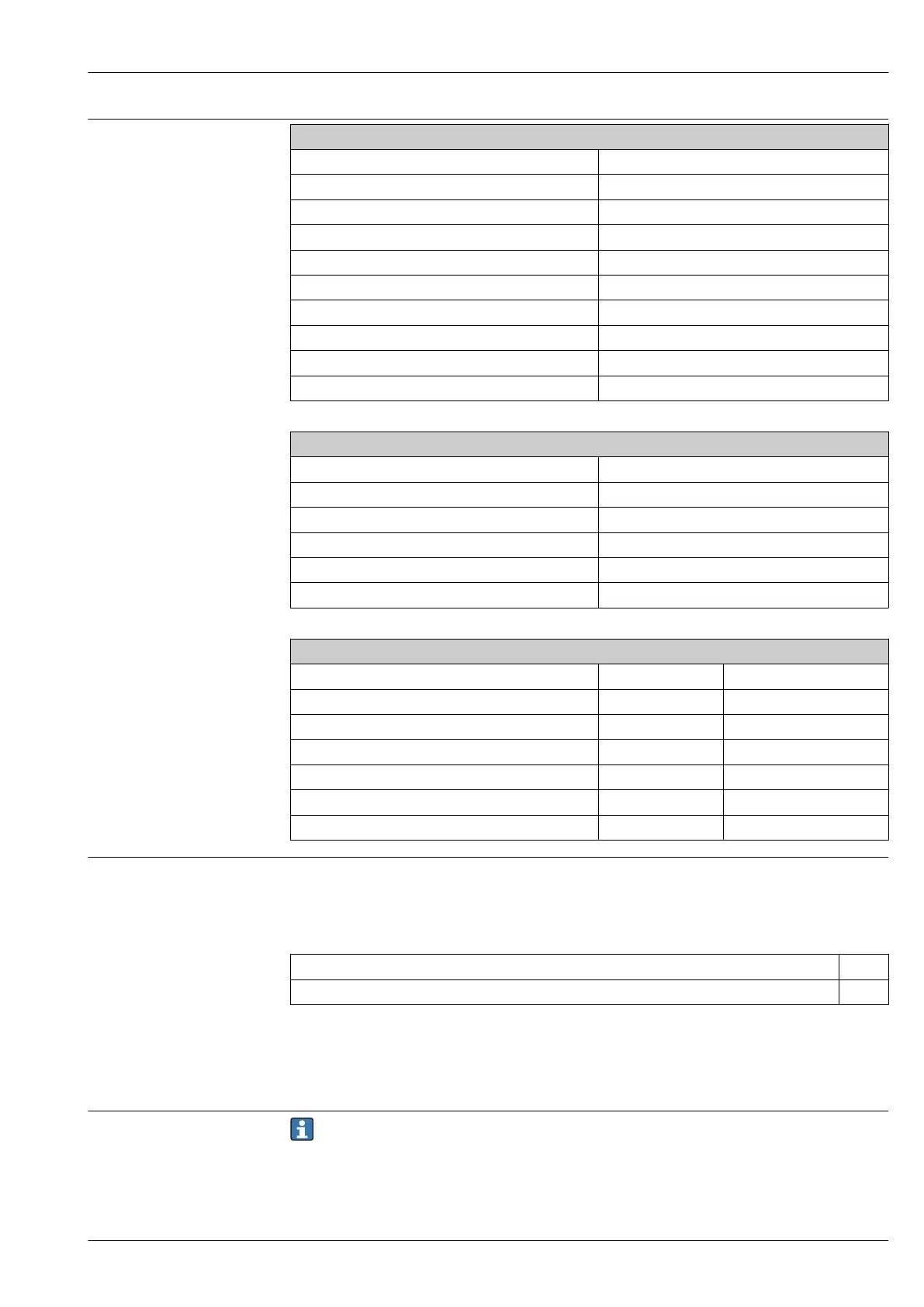

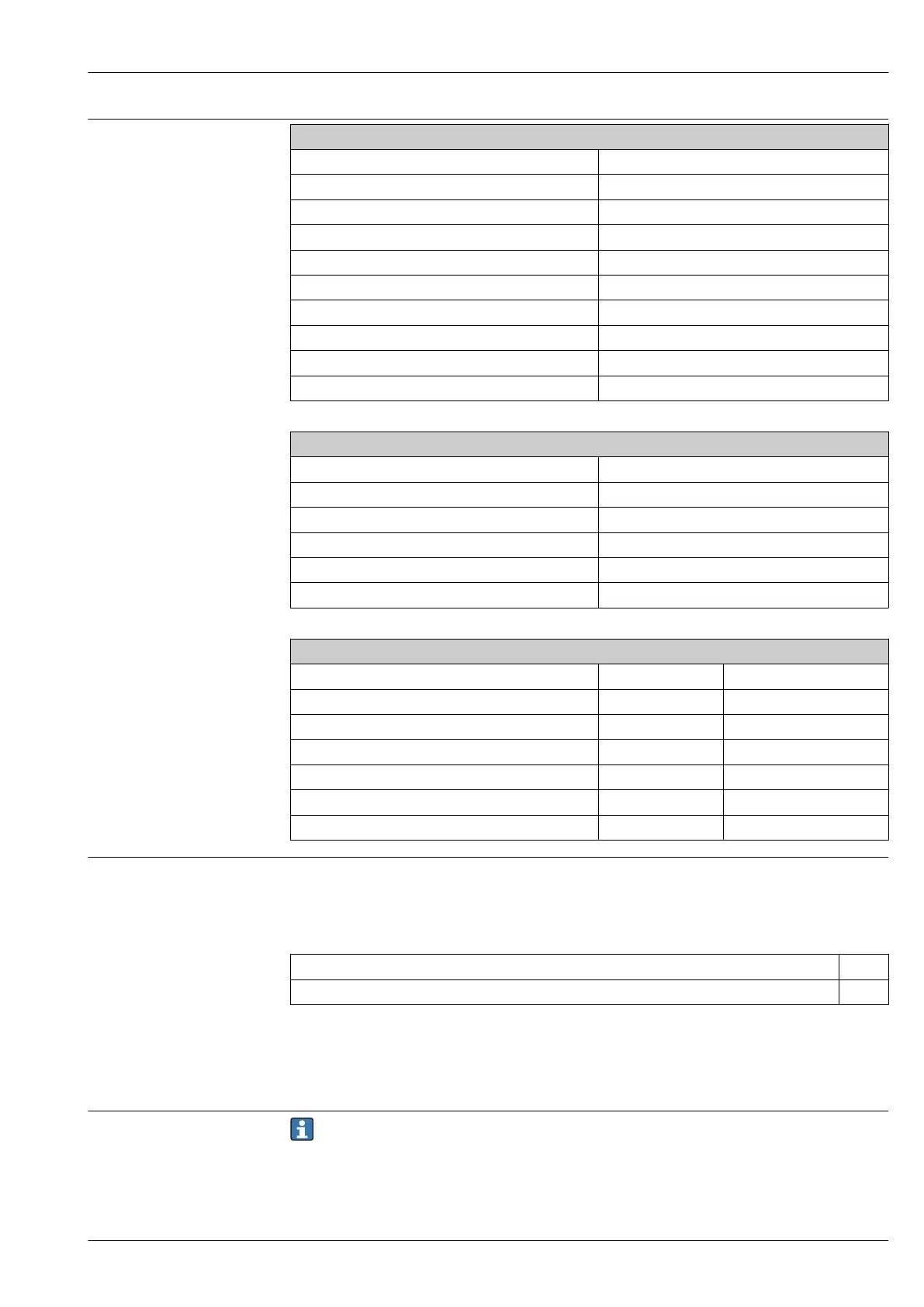

Proof-testing

System-specific data

Company

Measuring point/TAG no.

Facility

Device type/Order code

Serial number of device

Name

Date

Access code (if individual to each device)

Locking code used SIL 7452

Signature

Device-specific commissioning parameters

Upper density

Process condition

High stop level

Low stop level

Empty

Tank reference height

Proof-test protocol

Test step Set point Actual value

1. Current value 1

2. Current value 2

3. Current value 3 (if necessary)

4. Current value 4 (if necessary)

5. Current value 5 (if necessary)

Resistance value

Notes on the redundant

configuration of multiple

sensors

This section provides additional information regarding the use of homogeneous redundancy sensors

e.g. 1oo2 or 2oo3 architectures.

The common cause factors ß and ß

D

indicated in the table below are minimum values for the

Micropilot. These must be used when designing the sensor subsystem.

Minimum value ß with homogeneous redundant use 5%

Minimum value ß

D

with homogeneous redundant use 2%

The device meets the requirements for SIL 3 in homogeneous redundancy.

Please note the following when carrying out the proof-test: If an error is detected in one of the

redundantly operated devices, the other devices must be checked to see if there is the same error.

Further information

General information on functional safety (SIL) is available at:

www.de.endress.com/SIL (Germany) or www.endress.com/SIL (English) and in the Competence

Brochure CP01008Z/11 "Functional Safety in the Process Industry- Risk Reduction with Safety

Instrumented Systems".

Loading...

Loading...