A G-TRAC MANUAL

IOM-24 Page 16 March 1999 R1

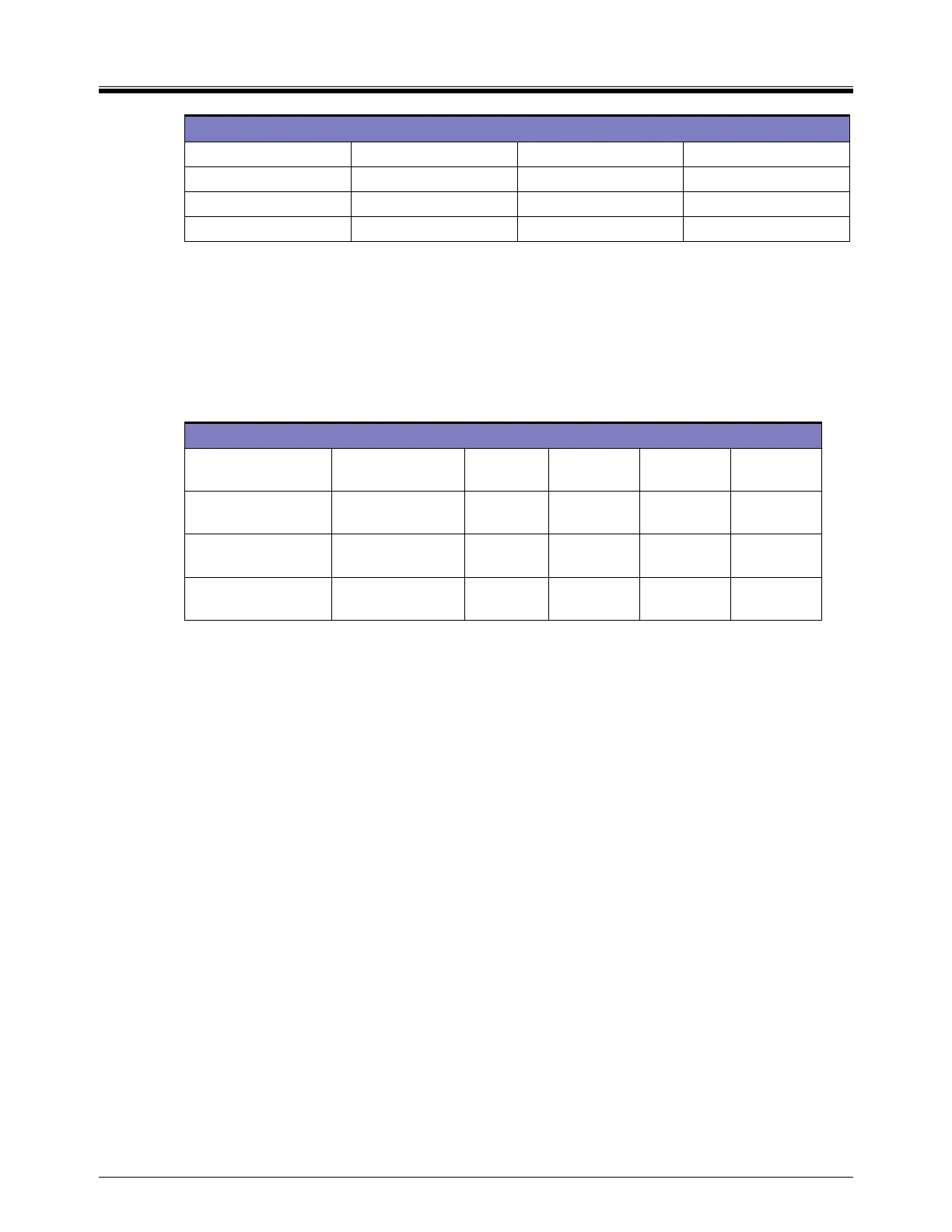

Time (Jumpers) Time (Jumpers) Time (Jumpers) Time (Jumpers)

0:0 (1111)

0:15 (0111) 0:45 (1011) 1:15 (0011)

1:45 (1101)

2:15 (0101) 2:45 (1001) 3:15 (0001)

3:45 (1110)

4:15 (0110) 4:45 (1010) 5:15 (0010)

5:45 (1100)

6:15 (0100) 6:45 (1000) 7:15 (0000)

TO SET THE MAINTAIN PURGE TIME DELAY

Maintain Purge Time Delay is set by cutting the “maintain purge” jumpers on the back of the G-TRAC

board. This is best to do before installing a new board. Cut the same jumpers as were cut on the old

board or contact the factory (after getting unit serial number) for correct jumper information. Maintain purge

time is determined by the speed that heat exchangers lose heat and control systems react. If purge has

turned off and there is another call for heat, then pre-purge must occur again which may create wide

discharge temperature swings. Turning the combustion fan off is only done as an energy management

step.

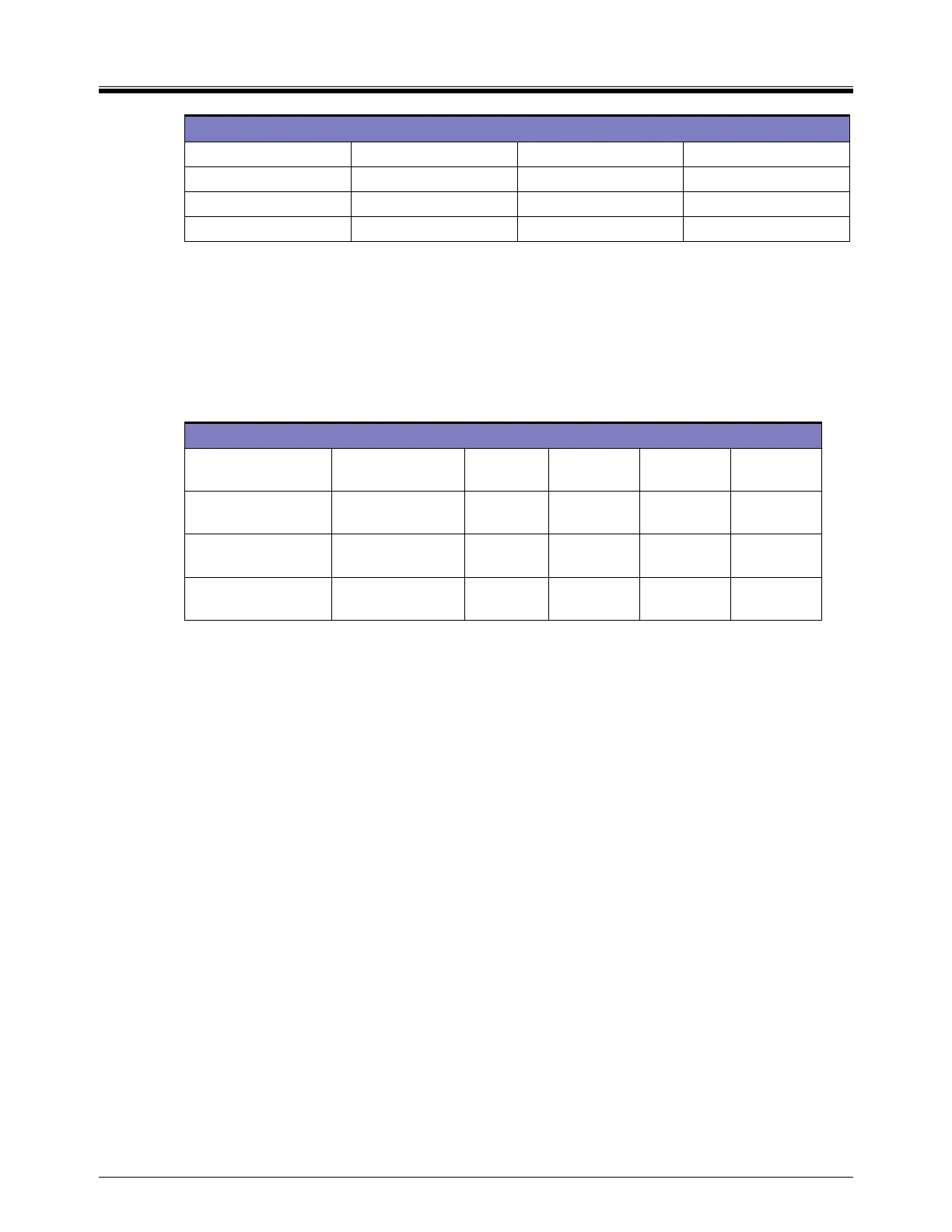

JUMPER CONNECTIONS

APPLICATION

TIME IN

MINUTES

MP-1 MP-2 MP-3 MP-4

ONLY ROOM

CONTROL

0:30 CUT JUMPER JUMPER JUMPER

MOST

APPLICATIONS

6.30 CUT CUT CUT JUMPER

CTRAC

CONTROL

2:30 CUT CUT JUMPER JUMPER

Cutting all MP jumpers allows a "maintain purge" time of 12 minutes (plus or minus 2 minutes).

ESTIMATED POT SETTINGS (Use for situations where design values not available)

If the old G-TRAC is available, there was a sticker inside the cover showing the pot settings as they left

our factory. If this is not available and the control was operating well before it failed, then match the pot

settings. Failing that:

POT 5 Valve Sensitivity Set at 3 (or slightly lower)

POT 6 Internal Control Band set at 3 (If G-TRAC is slave to a CTRAC then set this at 4)

POT 8 Burner ON/OFF Control Band If G-TRAC is slave to a CTRAC then set this at 4

POT 4 Auxiliary Set point Usually not used. Used only if there is a jumper “SP to

S” (main set-point) or “SP to Y” (reset set-point)

POT 1 Discharge Calibration Must be set as per instruction in manual

POT 3 Room Calibration Must be set as per instruction in manual. This is usually

as a room or return air reset rather than as room control.

Used only if V, X, Y, Z are wired

POT 2 Room Reset Ratio Used only if POT 3 is used. Used to determine how

much authority will be given to the reset

thermostat/sensor. Setting 1 is the minimum authority

(+/- 9ºF) and setting 5 is the maximum authority (+/-

32ºF).

POT 7 BMS RESET RATIO Used only if there is a BMS control wired to the BMS

input terminals “+ and –“ (1 is minimum reset authority and

5 is maximum authority).

Loading...

Loading...