DATE :

08/03/2023

SHEET:

1 of 1

SCALE:

NTS@A4

DRAWING No:

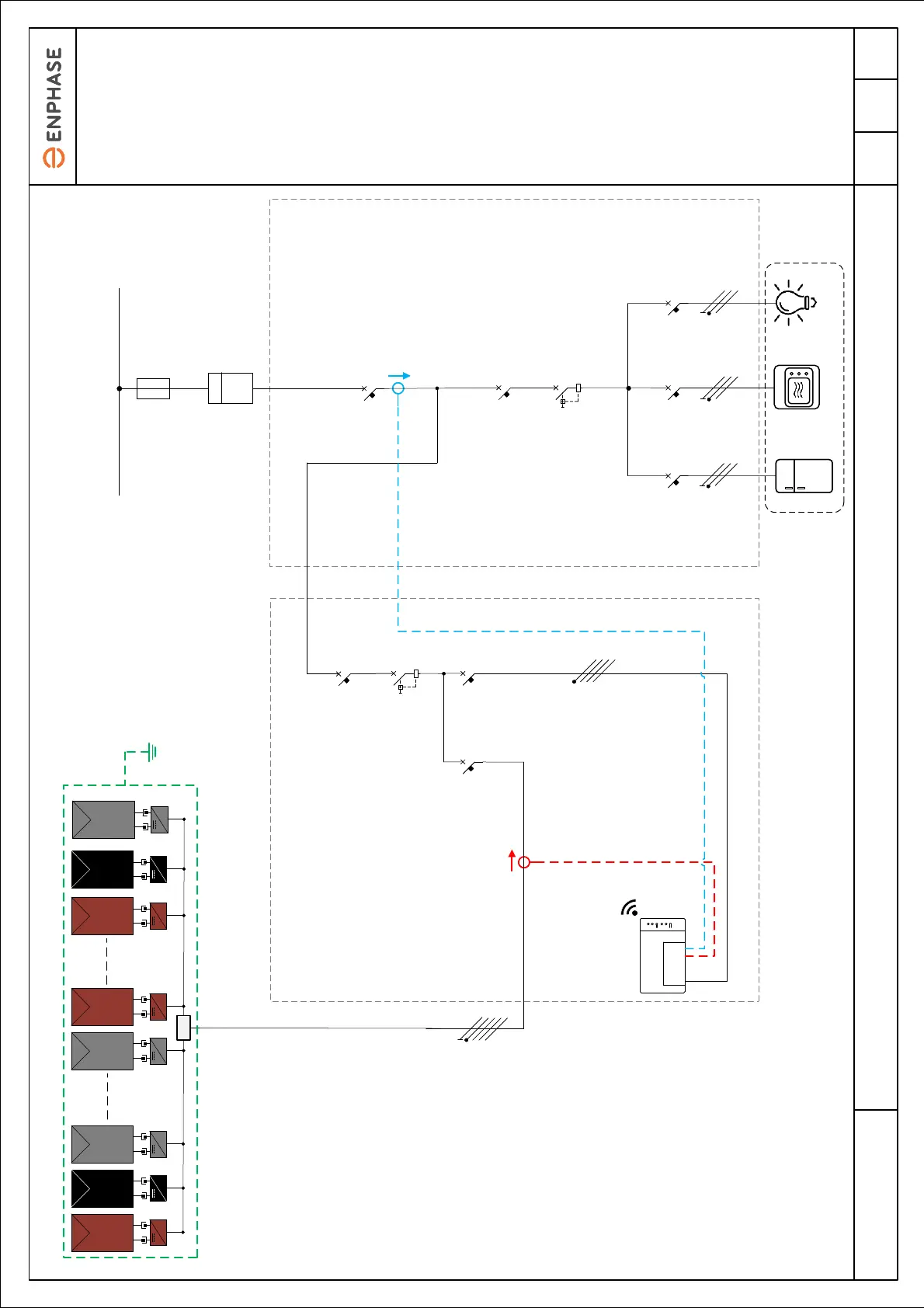

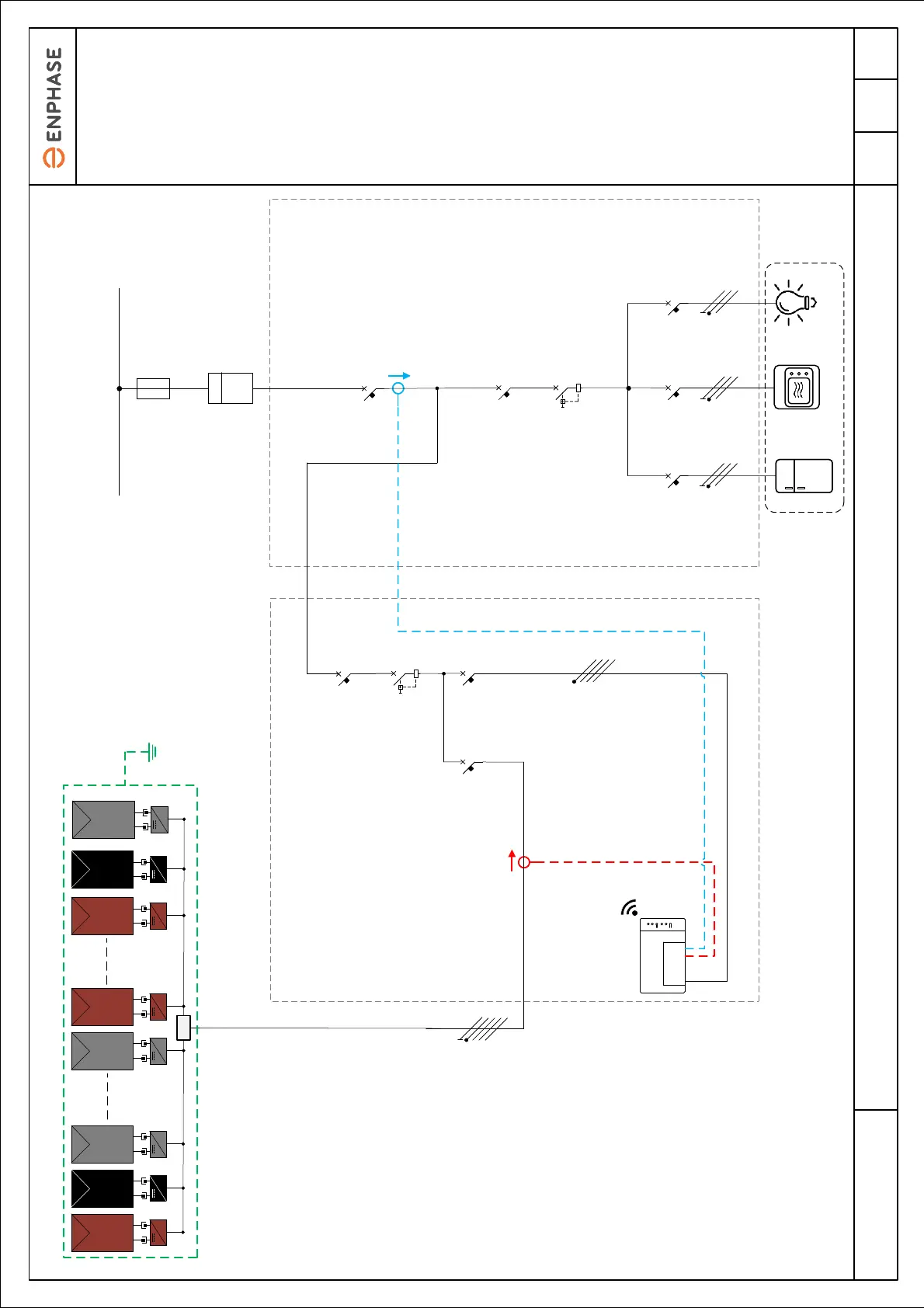

EN-IQ8-3PHN

DRAWING Name:

Electrical diagram example: Multi-phase IQ8 Series Microinverters (IQ8MC or IQ8AC or IQ8HC) Grid Tied PV System

Gateway internet connection:

- Ethernet LAN cable

- Wi-Fi

- Mobile Connect Cellular Modem

Gateway internet connection:

- Ethernet LAN cable

- Wi-Fi

- Mobile Connect Cellular Modem

Q1

1PH+N

Q1

1PH+N

Q2

1PH+N

Q2

1PH+N

Qn

1PH+N

Qn

1PH+N

Consumption measurement

CTs installed on Line

Conductors

Production measurement

CT installed on Line

Conductors

AC Cable 5 Core

(L1, L2, L3, N, PE)

6 mm² Minimum recommended

conductor size, see note 4

AC Cable 5 Core

(L1, L2, L3, N, PE)

6 mm² Minimum recommended

conductor size, see note 4

AC Cable 4x 2.5mm² (L1, L2, L3, N)AC Cable 4x 2.5mm² (L1, L2, L3, N)

MCB

3PH+N

20A

MCB

3PH+N

20A

MCB

3PH+N

6A

MCB

3PH+N

6A

Utility meter

See note 9

Utility meter

See note 9

kWhkWh

Main Breaker

3PH+N

Main Breaker

3PH+N

PV Sub-panelPV Sub-panel

Main PanelMain Panel

LoadsLoads

RCD - Consumption

3PH+N

See note 7

RCD - Consumption

3PH+N

See note 7

MCB - Consumption

3PH+N

Multi-phase IQ Cable 4x 2.5 mm²

(L1, L2, L3, N)

MCB - Production

3PH+N

40 A

MCB - Production

3PH+N

40 A

RCD - Production

3PH+N

40A, 30mA

See notes 7 and 8

RCD - Production

3PH+N

40A, 30mA

See notes 7 and 8

~~ ~~ ~~~~~~ ~~~~

~~

JB

L1-N L2-N L3-N

L1-N L2-N L3-N

L3-N L1-N

Maximum Microinverters per 20 A Circuit:

33x IQ8MC or 30x IQ8AC or 27x IQ8HC

(Maximum 16 A per phase)

Maximum 18 microinverters per

IQ Cable Section

Maximum 18 microinverters per

IQ Cable Section

NOTES:

1.These schematics are examples

only. These schematics provide

recommendations to assist the

system designer and installer.

2.The design and installation of the

photovoltaic power plant must be

carried out in accordance with local

electrical standards in the country

of installation and must be carried

out by competent personnel.

3.Before installing any PV

equipment, check the phase-to-

neutral voltage at the point of

connection. The operating voltage

must be within a range acceptable

for the 230 V microinverters.

4.The lengths and cross sections of

AC cable (between the end of the

IQ Cable and the electrical panel)

must be determined in accordance

with the electrical standards in

force in the country of installation. It

is recommended that the voltage

drop on this cable does not exceed

1% and that overall voltage drop in

the PV circuit from the point of

connection to the most remote

microinverter does not exceed 2%.

5.The 2.5 mm² IQ Cable is usually

protected by a 20 A B curve circuit

breaker.

6. The equipotential bonding

between PV module frames, array

mounting structure and the metal

microinverter mounting brackets

must be installed in accordance

with local electrical standards.

7. Surge protection devices (SPD)

and Residual Current Devices

(RCD) must be installed

accordance with local electrical

standards. Enphase microinverters

have an Internal surge protection.

8. Enphase microinverters have an

integrated High Frequency

transformer which provides

galvanic separation between DC

and AC parts. Where local

electrical standards require RCD

protection, a Type AC device can

be used.

9. Utility meter may be located

inside the main panel or as a

standalone device.

10. Use a G99 approved third party

network protection relay for PV

systems with system size above

17kW per phase.

Array structure

earthing where

required

See note 6

Public Electricity Network

(Grid connection)

IQ Gateway

Metered

Communication

Gateway

Loading...

Loading...