Section 7 Electrode mana

ement 43

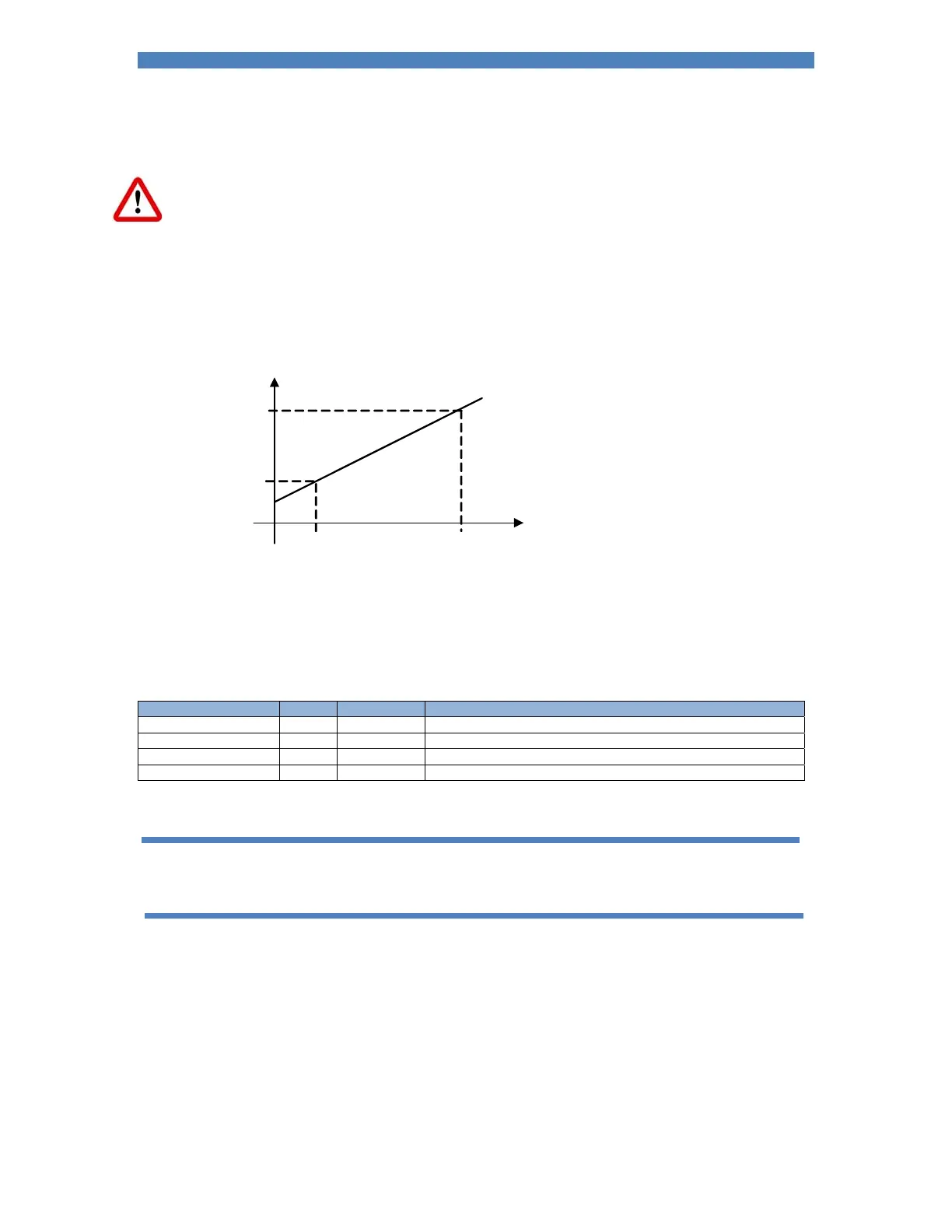

CCC calibration

The current must be calibrated before carrying out the following procedure.

When operating in CCu mode the inverter uses the Heat parameter to determine the output current. In

order to be able to control the output current directly in amps it is necessary to establish the relationship

between Heat and Current as follows:

Produce a short circuit weld at a low heat in CCu mode and note the heat setting (H1) from the

iPAK2 and the corresponding measured current (I1).

Repeat the short circuit weld at a higher heat and note Heat (H2) and Current (I2).

Enter these values as the ‘Points 1&2’ parameters in CCC calibration.

Heat

Current

H

2

H

1

I

1

I

2

The iPAK2 will use these values to determine the relationship between Heat and Current. CCC mode

can now be selected in the welding schedules and required current programmed directly in amps. The

Heat parameter is no longer required.

This calibration also assists the iPAK to produce a rapid rise-time to the desired current without causing

any significant transient conditions.

Parameter Units Range Description

Point 1 (heat) % 0

99.9 The set value of low heat (H1)

Point 1 (current) kA 0 - 500.0 The measured value of current at a low heat (I1)

Point 2 (heat) % 0

99.9 The set value of high heat (H2)

Point 2 (current) kA 0 - 500.0 The measured value of current at a high heat (I2)

In multi-electrode systems there are separate calibration files for each gun. Each electrode must be

calibrated before being used.

Loading...

Loading...